A diaphragm pump is the maximum well-known sort of pump in the class of superb displacement pumps. It is likewise known as a Membrane pump. For pumping a fluid, a diaphragm pump makes use of a mixture of the reciprocating movement of the diaphragm manufactured from Teflon, thermoplastic, or rubber with the corresponding valves (globe valves, flap valves, butterfly valves, take a look at valves, or every other sort of valves) on each facet of the diaphragm.

These types of pumps are widely used in many factories because they can handle large volumes of liquids. Diaphragm pumps are well known for their ability to pump high, medium, or low viscosity liquids and high solids liquids. This pump can also be made from a variety of body materials and diaphragms to process a variety of harsh chemicals such as acids.

Table of Contents

Diaphragm Pump Working Principle

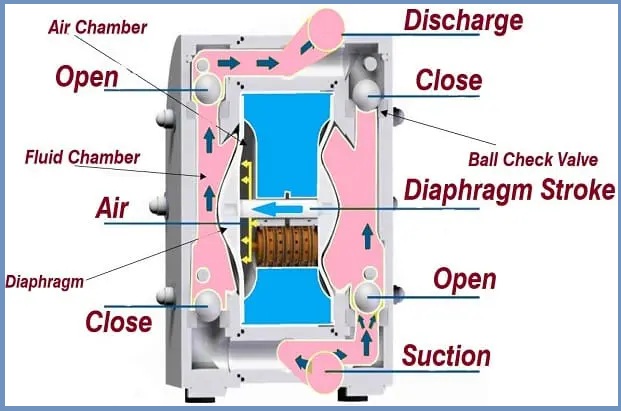

A diaphragm pump is a positive displacement pump that uses two flexible diaphragms that move back and forth to form a temporary vacuum. This vacuum is used to suck or discharge liquid from the diaphragm pump. The membrane acts as a barrier between the liquid and the air.

I have described the complete working principle of the diaphragm pump.

Stroke 1:

The two diaphragms are connected by a shaft through the central part, in which the air valve is located. The air valve is used to push the compressed air behind the first diaphragm and out of the middle. The first diaphragm creates a pressure stroke to draw the liquid out of the pump. At the same time, the second diaphragm performs the suction stroke. The air behind the 2nd diaphragm is released into the atmosphere and atmospheric pressure forces the liquid towards the suction. The suction valve pushes out of the saddle and liquid flows through the ball valve into the pump’s fluid chamber.

Stroke 2:

When the pressurized first diaphragm reaches the end of its stroke, the air is transferred from the first diaphragm to the back of the second diaphragm through the air valve. Pressurized air pushes the second diaphragm away from the center of mass and the first diaphragm is pulled into the center of mass. In the second chamber of the pump, the discharge ball valve is pushed out of its seat, while in the first chamber the opposite situation occurs. When the second stroke is complete, the air valve pumps air behind the first diaphragm, and the whole cycle repeats.

Popular Types of Diaphragm Pumps

Here is the list of famous types of diaphragm pumps.

- Air-Operated Double Diaphragm Pump

- Motor-Driven Pump

- Small Motor Driven Pump

- Small Air-Operated Pump

- Wanner Hydra-Cell Pump

Uses/Applications

- Mixing tank

- Filling machine

- Color filter

- Pigment bar

- Filter press

- 55-gallon drum transfer

- Airspray-Supply or Transfer

- General unloading

- Powder coating