Table of Contents

Definition:

Air brake system means a system that uses air as a medium to transfer pressure or force from the driver’s action to the service brakes.

Air brake system does not include systems that use compressed air or vacuum solely to assist the rider in applying muscular force to hydraulic, electrical, or mechanical components.

Air brakes are a type of friction brake for vehicles that forces compressed air against a piston to apply the necessary pressure to the brake pads or shoes to stop the vehicle. Air brakes are used on large and heavy vehicles, especially vehicles with multiple trailers that need to be connected to the braking system, such as trucks, buses and trailers.

How Air Brakes System Works?

This system mainly consists of a compressor, air filter, reservoir, valves and brake pads. Compressors take air from the atmosphere through a filter and compress it. This pressurized air is directed through a relief valve to a reservoir that is raised or opened at a given reservoir pressure. This air supply to the brake chamber, also called diaphragm unit, is located at each wheel via a brake valve.

The brake valve is controlled by the driver and can control the strength of the brakes on demand. When the rider squeezes the brake lever, the pressure in the reservoir drops, pushing the brake pads toward the type to apply the brakes.

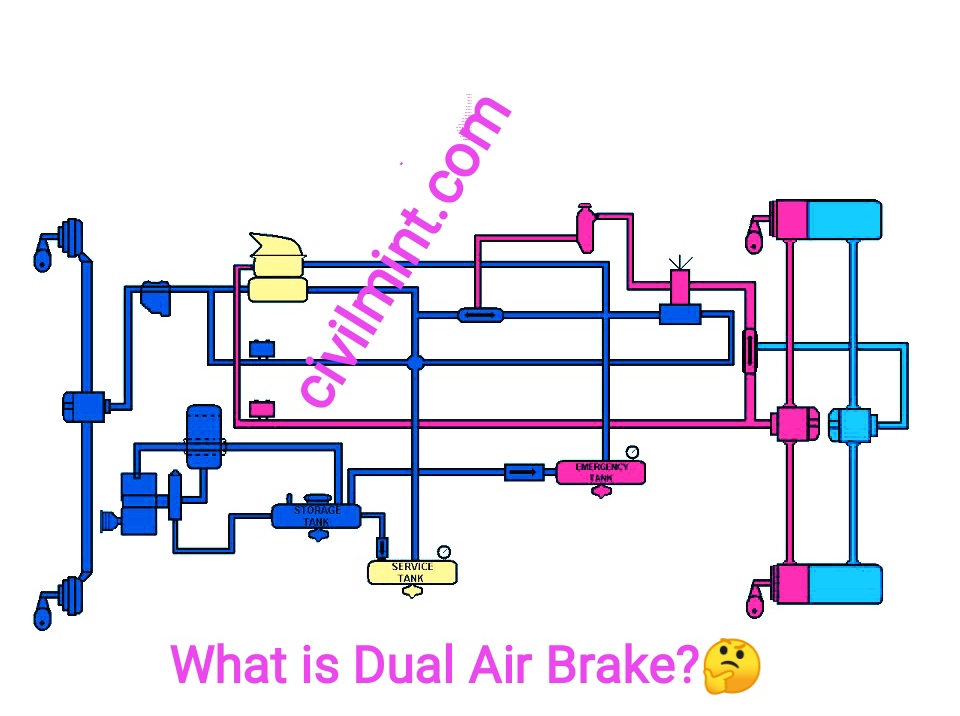

Dual Air Brake System

Equipped with a dual air brake system. Two independent air brake systems with one air brake system. A set of brake controls. Each system has its own air. Tanks, hoses, lines, etc.

A dual circuit braking system completely separates the front hydraulic lines and brake components from the rear. This means that even if the front brake suffers a catastrophic loss of pressure, the driver can rely on his rear brake to bring the car to a halt.

Advantages of Air Brake System

- The air supply is unlimited so the braking system does not run out of hydraulic fluid as it does with hydraulic brakes. Small leaks do not lead to brake failure.

- Air line couplers are easier to connect and disconnect than hydraulic lines. Eliminates the risk of air in the hydraulic fluid and the need to bleed the brakes during servicing. Trailer air brake circuits are easy to install and remove.

- In addition to acting as a power transmission fluid, air stores potential energy when compressed and can be used to control the force applied. Hydraulic fluids are mostly incompressible.

- The airbrake system includes an air tank that stores enough energy to stop the vehicle if the compressor fails.

- Air brakes are effective even in the event of a severe leak, so the air brake system should be designed with sufficient “fail-safe” capacity to safely stop the vehicle in the event of a leak

- The system-specific compressed air can be used for ancillary applications where hydraulics are not suitable, such as Air horns, seat adjusters, bus and trolleybus doors.

Disadvantages

- Air brakes are generally expensive.

- Because air brake systems compress air, the moisture must be removed with an air dryer, which can increase the price of air brake systems and increase maintenance and repair costs.