In this article, we are going to discuss very important topic for civil engineers. Most of the fresher engineers don’t have any idea how to make bar bending schedule for a beam.

Table of Contents

Introduction

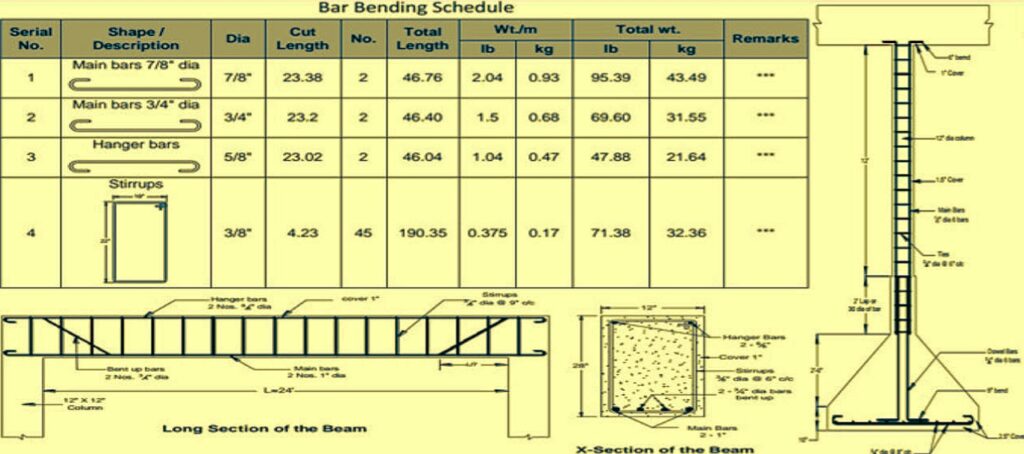

A Bar Bending Schedule (BBS) is a detailed calculation that lists the type, size, and number of reinforcement bars required for specific structure. It is used to ensure that the correct amount of steel reinforcement is used in a concrete structure, and that it is placed in the correct location.

A civil engineer should have basic understanding of reinforcement cement concrete (RCC). Otherwise, it can be difficult to understand bar bending schedule.

Description And Formulas

Before creating the BBS, it is important to have a clear understanding of the design of the beam and the loads it will be subjected to. This information can be obtained from the structural design calculations, which should be carried out by a qualified engineer.

The first step in creating the BBS is to determine the size and type of reinforcement required. This is determined by calculating the steel reinforcement area (As) required for the beam using the following formula:

As = (My)/(f’cd)

Where:

M = moment in the beam.

y = distance from the extreme compression fiber to the centroid of the steel reinforcement.

f’c = concrete compressive strength

d = depth of the beam

Once the As has been calculated, the next step is to determine the number and size of reinforcement bars required.

The number of bars is calculated using the following formula:

Number of bars = As / (bar size * bar spacing)

The size of the reinforcement bars can be selected from the standard sizes available, and the spacing should be such that it complies with the minimum and maximum requirements as per the standard codes.

Next, the length of each bar is calculated. This is done by measuring the length of the beam and subtracting the clear cover (the distance between the outermost reinforcement and the concrete surface) from it. The length of the reinforcement bars should also take into account the development length (the length required for the bar to properly bond with the concrete), which is calculated using the following formula:

Development length = (50f’csqrt(fy))/fy

Where:

f’c = concrete compressive strength

fy = yield strength of the reinforcement steel

The final step is to create the BBS. This is a detailed document that lists the type, size, and number of reinforcement bars required, as well as their length and location in the beam. It should also include any special requirements such as hooks, bends, or stirrups.

Sum Up

Developing a Bar Bending Schedule (BBS) for a beam is an essential part of guaranteeing that the right amount and type of steel reinforcement is employed in a concrete structure. It is vital to possess a thorough comprehension of the beam’s design and the forces it will be exposed to, and to apply the correct equations to determine the steel reinforcement area, number and size of bars, and their length. The final BBS should be a comprehensive document that includes all the required information for building the beam.

FAQS

What is the purpose of creating a Bar Bending Schedule (BBS) for a Beam?

A BBS serves as a blueprint for the steel reinforcement required for a beam, ensuring the correct amount and type of steel is used to maintain the structural integrity and safety of the beam.

Who is responsible for creating a BBS for a Beam?

A BBS for a beam is typically created by a structural engineer or a draftsman, using information from architectural and structural drawings of the building.

What types of information does a BBS for a Beam include?

A BBS includes information such as the type and size of steel bars, the shape of the beam, the number of bars required, length of each bar, and the shape of each bend.

How is steel reinforcement cut and bent according to a BBS?

Specialized machinery and tools are used to cut and bend the steel reinforcement according to the specifications listed in the BBS.

How is steel reinforcement placed and secured in a beam according to a BBS?

Steel reinforcement is carefully positioned and secured in a beam using binding wire or other fastening methods, as per the specifications in the BBS.

How is the quality of steel reinforcement checked according to a BBS?

A quality control inspector checks the steel bars for any defects or damages, such as cracks or rust, and ensures that they meet the specifications listed in the BBS.

What is the process for inspecting and approving steel reinforcement according to a BBS?

A structural engineer or other qualified professional will review the BBS and inspect the steel reinforcement to ensure that it meets all the requirements for the beam.

What are the common mistakes that can occur in a BBS for a Beam?

Common errors include incorrect calculations of steel reinforcement, incorrect specifications for the type and size of steel bars, and errors in the shape or size of the beam.

How can errors in a BBS for a Beam be corrected?

Errors can be corrected by reviewing the BBS, making necessary adjustments, and consulting with a structural engineer or other qualified professional for verification.

How does a BBS for a Beam contribute to the safety and longevity of a construction project?

A BBS ensures the correct amount and type of steel reinforcement is used, thereby contributing to the structural integrity and safety of the beam, ultimately promoting the longevity of the construction project.