Table of Contents

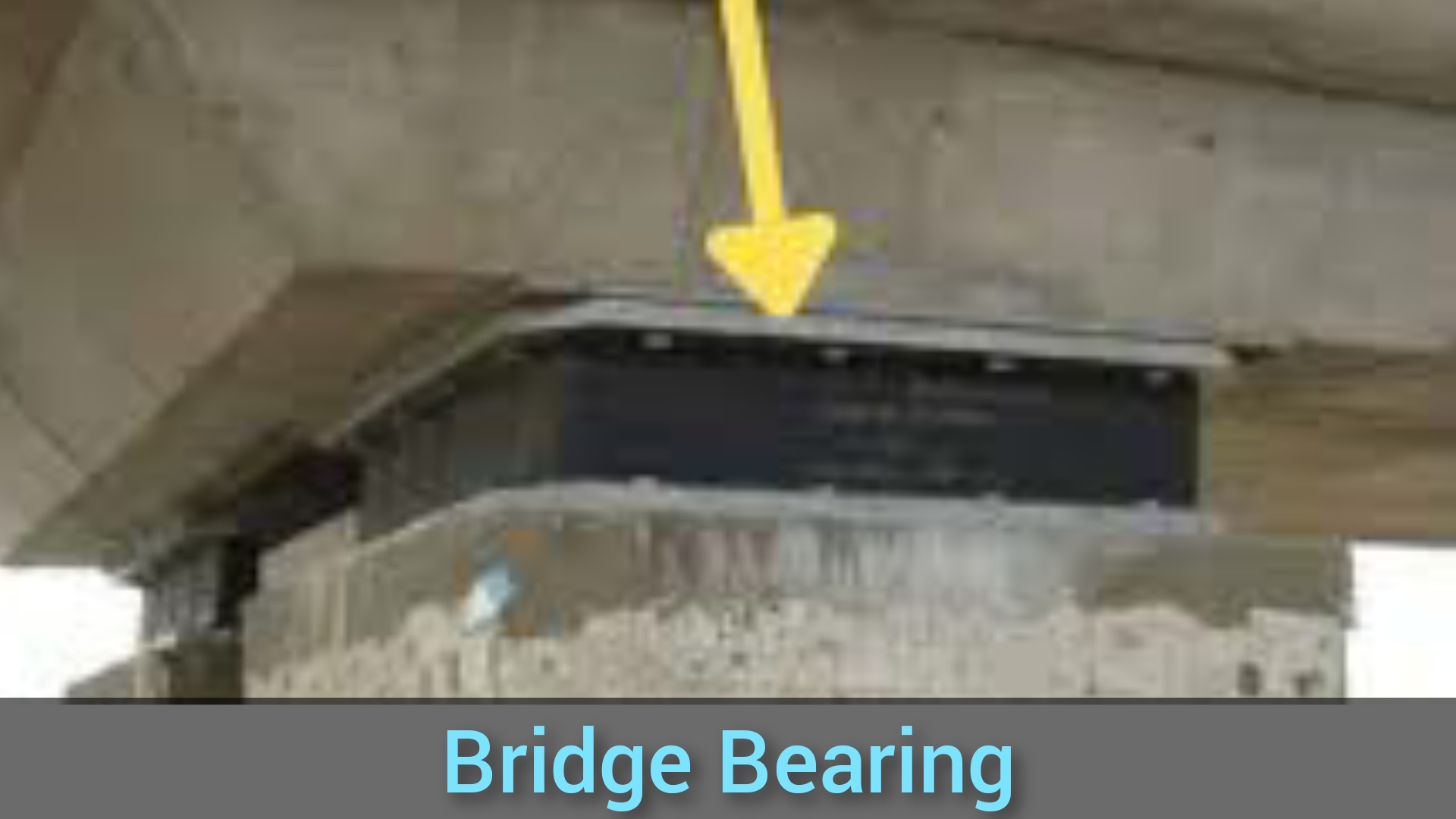

What Is Bridge Bearing?

A bridge bearing typically offers a resting surface between bridge piers and the bridge deck. The bridge bearing component plays a role in providing a resting surface between bridge piers and the bridge deck. A bridge typically relies on a bridge bearing to provide a resting surface between bridge piers and the bridge deck.

Description

A bearing serves the purpose of facilitating controlled movement and minimizing stress. This movement may arise due to a variety of factors such as thermal expansion and contraction, creep, shrinkage, or material fatigue.

External factors like ground settlement, thermal expansion, and seismic activity can also cause movement. Bridge bearings are available in various types that are selected based on factors such as bridge span, loading conditions, and performance requirements.

The simplest form of bridge bearing is two plates placed on top of each other. Elastomeric bridge bearings and mechanical bridge bearings are the two most common types. Mechanical bridge bearings are further classified into pinned bearings, including specific types like rocker bearings and roller bearings. Fixed bearings are another mechanical bearing type that allows rotation but restricts other forms of movement.

Bridge Bearing Functions

Bridge bearings are structural components that facilitate the transfer of forces between the bridge superstructure and substructure. They are designed to support vertical loads such as the weight of the structure and vehicle loads, as well as lateral loads such as wind and earthquake forces.

One important function of bridge bearings is to accommodate movements such as translation and rotation between girders and pier caps, which can occur due to thermal expansion or other factors. This helps to prevent damage to the bridge and ensure its long-term stability.

Neoprene bearing pads are a type of bridge bearing that is made of rubber-like material. These pads are designed to absorb energy through deformation, which helps to simplify the load transfer mechanism and make analysis easier.

Types Of Bridge Bearing

Here are some common types of bridge bearings.

1. Rocker Bearings

Rocker bearings feature curved surfaces that enable rocking and facilitate horizontal movement as the bridge expands. Typically composed of steel, they are commonly used in highway bridges.

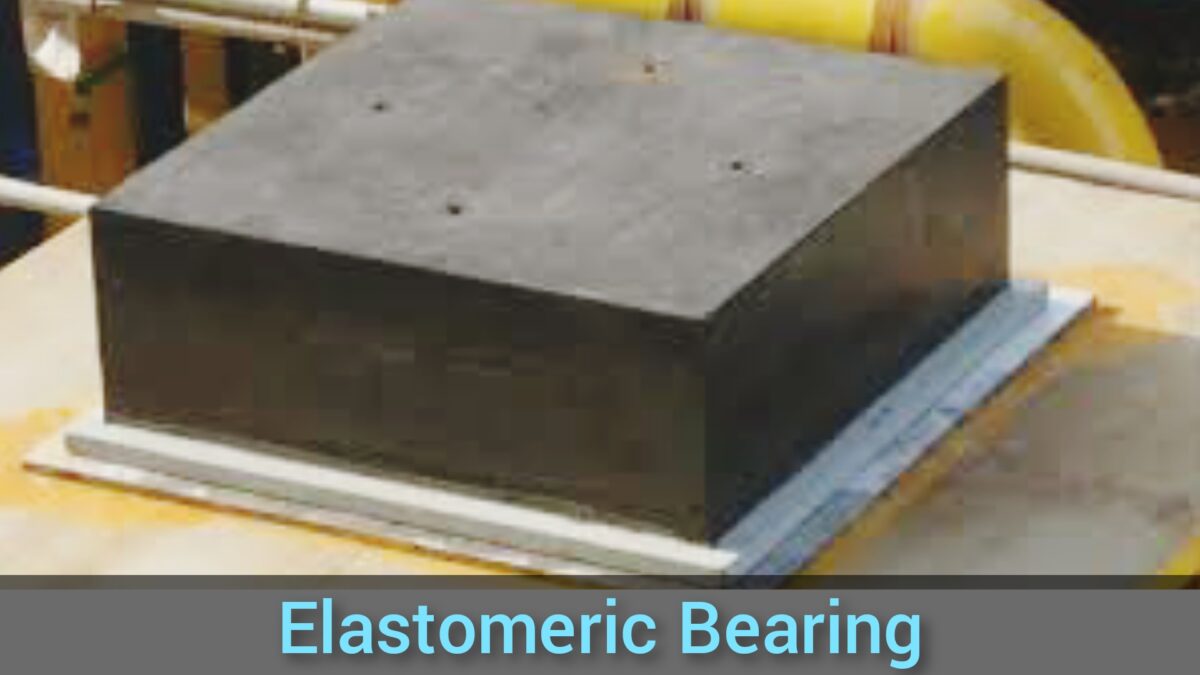

2. Elastomeric Bearings

Elastomeric bearings are the most prevalent type of bridge bearing used today. These bearings are made of rubber and do not have any moving components, as the rubber material allows for bridge movement. They are relatively inexpensive to manufacture and require minimal maintenance, unlike other bearing types with metal components that require regular upkeep. Steel reinforcement can be added to elastomeric bearings to enhance their strength if necessary.

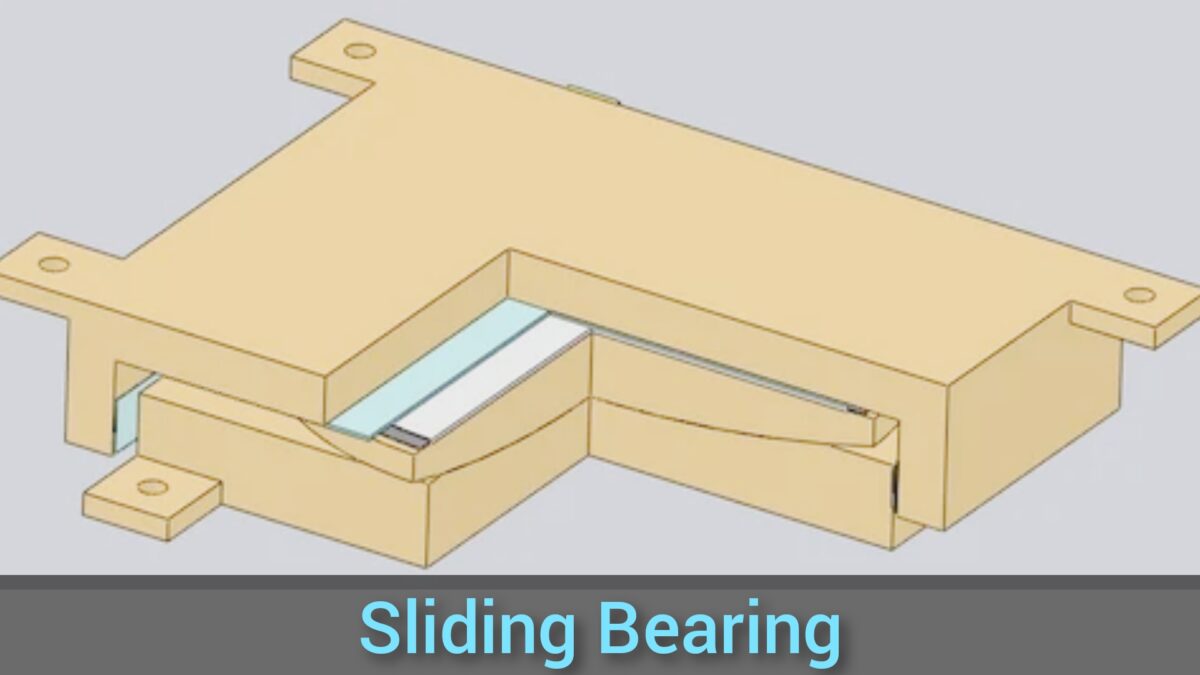

3. Sliding Bearings

Sliding bearings have a flat sliding surface that permits horizontal movement and a spherical surface that enables rotation. Although they were traditionally made of metal, Teflon is now commonly used to create sliding bearings.

4. Spherical Bearings

As their name implies, spherical bearings are spherical in shape. These bearings only allow for rotation and restrict movement in the horizontal and vertical directions.

Selection Of Bridge Bearings

When it comes to designing a successful bridge structure, the performance of the bearing is crucial. Therefore, careful consideration should be given to several factors when selecting the appropriate bridge bearing.

The first factor is the bearing’s ability to handle high vehicle loads. It should be able to withstand the weight of heavy vehicles passing over the bridge without buckling or deforming.

Another important factor is the bearing’s movement capability. It should allow for the expansion and contraction of the bridge due to temperature changes, as well as any other movements caused by wind, traffic, or other external forces.

Rotational capability is also essential in selecting a suitable bearing. The bearing should allow the bridge to rotate smoothly without causing any damage or excessive wear and tear.

The bearing must also have the capacity to resist external horizontal forces, such as wind. It should be able to maintain its stability even in the face of strong winds or other environmental conditions.

Seismic resistance is another crucial factor to consider when selecting bridge bearings. The bearings should be able to withstand the effects of earthquakes and other seismic activity without compromising the bridge’s stability or safety.

Cost is always a significant factor in any construction project. Therefore, the overall cost of the bridge bearing should be kept low without sacrificing its performance or safety.

Environmental conditions should also be taken into account when selecting bridge bearings. Bearings that are prone to corrosion should not be used in areas with high humidity or near water bodies. Roller bearings and sliding bearings may not be suitable for dusty areas.

Design Considerations For Bridge Bearings

Designing bridge bearings requires careful consideration of several factors, including:

1. Load Capacity:

Bridge bearings must be designed to handle the loads that will be placed on them, including the weight of the bridge deck, the weight of the vehicles, and any other loads that may be applied to the bridge.

2. Movement Capacity:

Bridge bearings must be designed to accommodate the movements of the bridge deck due to temperature changes, wind, and other environmental factors. The bearings must also be designed to accommodate any anticipated future movements of the bridge deck.

3. Durability:

Bridge bearings must be designed to withstand the harsh environment in which they will be installed. This includes exposure to weather, salt spray, and other corrosive elements.

4. Maintenance:

Bridge bearings must be designed to allow for easy maintenance and replacement. This is essential for ensuring the longevity and safety of the bridge.

Maintenance of Bridge Bearings

Proper maintenance of bridge bearings is essential for ensuring the longevity and safety of the bridge. Maintenance practices for bridge bearings typically include:

1. Regular Inspection:

Regular inspections of the bridge bearings should be conducted to identify any signs of wear or damage. Inspections should be conducted by trained professionals and should follow established inspection protocols.

2. Cleaning:

Bridge bearings should be cleaned regularly to remove any debris or contaminants that may have accumulated on or around the bearings. This is essential for ensuring that the bearings can function properly and for preventing corrosion.

3. Lubrication:

Bridge bearings should be lubricated regularly to ensure that they can move freely and without excessive friction. The type and frequency of lubrication will depend on the type of bearings installed and the environmental conditions in which the bridge is located.

4. Replacement:

Bridge bearings may need to be replaced over time due to wear, damage, or other factors. Replacement should be conducted by trained professionals and should follow established replacement protocols.

Sum Up

Bridge bearings are essential components of bridges, providing support to the bridge deck while allowing it to move freely under different loads. There are different types of bridge bearings, each with its own advantages and limitations. When designing bridge bearings, engineers need to consider load capacity, movement capacity, durability, and maintenance requirements.

Proper maintenance of bridge bearings is critical for ensuring the bridge’s longevity and safety. Bridge owners can ensure that their bridges remain safe and operational for many years by following established maintenance practices.

Choosing the appropriate bridge bearing is a critical aspect of bridge design. The selected bearing must be able to handle high vehicle loads, have movement and rotational capabilities, resist external horizontal forces, possess good seismic resistance, be cost-effective, and suitable for the environmental conditions. Engineers carefully consider these factors when designing bridge bearings to ensure the safe and effective operation of the bridge.