Table of Contents

What Is Circular Prestressing?

Circular Prestressing is used to refer to the prestressing of circular elements such as pipes and tanks in which the prestressed wire is wound in a circle.

In contrast to this term, “linear prestressing” is used to refer to any other type of prestressing in which a cable is straight or bent but not twisted in a circle around a circular structure.

In most prestressed circular structures, prestresses are applied in both the circumferential and longitudinal directions, where circumferential prestress are circular and longitudinal prestresses are virtually linear.

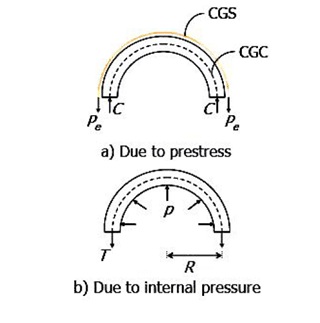

The circumferential prestress resists hoop stress due to internal pressure. Prestressing is carried out by means of wires or stiffeners arranged in a spiral or along with sectors around the element. Wires or cores are placed outside the concrete core. Therefore, the center of the prestressed steel (CGS) is on the outside of the core concrete cross-section.

When the prestressing element is bent in the prestressing direction, the prestressing is called hoop prestressing. For example, circumferential prestressing of pipes, tanks, silos, protective structures, etc. is a type of circumferential prestressing. Prestressing in the longitudinal direction (parallel to the axis) is also possible in these structures.

Circular prestressing is also applied to the dome and shell. The circumferential prestress resists hoop stress due to internal pressure. Prestressing is carried out by means of wires or stiffeners arranged in a spiral or along with sectors around the element. Wires or cores are placed outside the concrete core. Therefore, the center of the prestressed steel (CGS) is on the outside of the core concrete cross-section. The resulting annular compression is assumed to be uniform across the thickness of the thin shell. Therefore, the pressure line (or Cline) is centered on the main concrete section (CGC).

The following figure shows the internal forces under operating conditions. The analysis is performed for unit length cuts in the longitudinal direction (parallel to the axis). Liquid holding structures such as around pipes, tanks, and pressure vessels are excellent for hoop prestressing. The circumferential hoop compression induced in the concrete by prestressing balances the hoop stress due to internal fluid pressure. Reinforced concrete pressure pipe has a crack-free structure because a large amount of reinforcement is required to provide low tensile stress. However, circular prestressing eliminates cracks and saves material. Prestressing also protects against shrinkage cracking of the fluid-retaining structure.

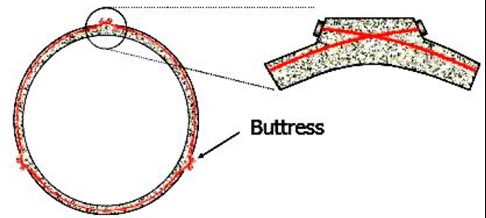

To reduce prestressing losses due to friction, prestressing can be performed in a sector of a circle. Buttresses are used to hold tendons in place. The following sketch shows the support around the circumference.

Advantages Of Circular Prestressing

1. Increased Structural Strength:

Circular prestressing significantly improves the structural strength of concrete elements such as tanks, silos, water pipes, and containment vessels.

The technique helps to counteract the tensile stresses that can occur due to internal or external pressure, enhancing the load-carrying capacity of the structure.

2. Improved Crack Control:

By introducing prestressing tendons in a circular pattern, the technique helps to minimize cracking in concrete elements.

The applied tension in the circumferential direction reduces the formation and propagation of cracks, increasing the overall durability and longevity of the structure.

3. Enhanced Load-carrying Capacity:

Circular prestressing allows for a more efficient distribution of loads.

By inducing compressive stresses in the circumferential direction, it increases the capacity of the structure to resist external forces, such as internal pressure or live loads.

This can result in the ability to carry higher loads without compromising the structural integrity.

4. Reduction In Material Usage:

Circular prestressing can lead to a reduction in the overall material requirements for a structure.

By introducing prestressing tendons, the concrete elements can be designed to carry higher loads with smaller cross-sectional areas.

This can result in cost savings and a more sustainable approach to construction.

5. Improved Structural Behavior Under Dynamic Loads:

Circular prestressing helps to improve the dynamic behavior of structures subjected to dynamic loads, such as seismic forces or wind-induced vibrations.

The prestressing tendons enhance the stiffness and damping characteristics of the structure, reducing its response to vibrations and increasing its resistance to dynamic forces.

6. Flexibility In Design:

Circular prestressing offers flexibility in the design of concrete structures.

The prestressing tendons can be arranged in various patterns and layouts, allowing for customization based on the specific requirements of the project.

This adaptability makes circular prestressing suitable for a wide range of applications and structural geometries.

7. Reduction In Maintenance And Repair Costs:

The enhanced durability and crack control provided by circular prestressing can lead to reduced maintenance and repair costs over the life cycle of the structure.

The minimized cracking and improved structural performance contribute to increased longevity and reduced need for ongoing maintenance and repairs.

Disadvantages Of Circular Prestressing

1. Complexity And Cost:

Implementing circular prestressing requires specialized knowledge, expertise, and equipment.

The process of placing and tensioning the tendons in a circular pattern can be more complex and time-consuming compared to traditional linear prestressing methods.

This complexity can increase construction costs, especially for smaller projects with limited budgets.

2. Limited Application:

Circular prestressing is mainly suitable for structures that have a circular or ring-shaped geometry, such as silos, storage tanks, and circular bridges.

It may not be feasible or practical to use circular prestressing for structures with non-circular geometries, limiting its applicability in certain construction projects.

3. Maintenance Challenges:

Circular prestressed structures can present challenges in terms of maintenance and repair.

Accessing and inspecting the tendons located within the circular members can be difficult, leading to increased costs and potential delays in identifying and addressing any maintenance or repair needs.

4. Non-uniform Stress Distribution:

Circular prestressing tends to result in a non-uniform stress distribution within the structural member.

The tensioned tendons apply higher stresses to the inner surface of the circular member, while the outer surface experiences lower stresses.

This non-uniform distribution of stresses can lead to differential deformations and potential cracking in the concrete, requiring careful design considerations.

5. Limited Flexibility:

Circular prestressed structures may have limited flexibility compared to non-prestressed or conventionally reinforced concrete structures.

The applied prestressing forces tend to create a state of initial compression in the concrete, reducing the flexibility and ductility of the structure.

This limited flexibility may not be desirable in some situations, such as seismic-prone areas where ductility is crucial to withstand earthquakes

Applications Of Circular Prestressing

1. Pre-stressed Concrete Pipes:

Circular prestressing is commonly used in the manufacturing of pre-stressed concrete pipes.

The tendons are arranged in a circular pattern around the inner circumference of the pipe, providing additional strength and load-carrying capacity.

2. Storage Tanks And silos:

Circular prestressing is employed in the construction of storage tanks and silos to increase their structural integrity and resistance to external forces, such as wind and seismic loads.

The tendons are positioned circumferentially to counteract tensile stresses and prevent cracking or failure.

3. Domes And Shells:

Circular prestressing is ideal for creating large-spanning structures like domes and shells.

By applying tensioned cables in a circular pattern, these structures can withstand the significant compressive forces they experience and distribute the loads evenly across the surface.

4. Circular Beams And Arches:

Circular prestressing can enhance the load-carrying capacity of circular beams and arches.

The tendons are placed in a circular arrangement along the length of the beam or arch to counteract the tensile stresses and increase their overall strength and stability.

6. High-rise Buildings:

Circular prestressing can be employed in tall buildings to improve their resistance to lateral loads and reduce deflections.

By introducing a circular pattern of prestressing tendons in the floors or around the core of the building, the structure becomes more robust and capable of withstanding wind and seismic forces.

7. Bridge Construction:

Circular prestressing is utilized in the construction of bridge structures, particularly for the construction of cable-stayed and suspension bridges.

The circular arrangement of prestressing tendons in the bridge deck or pylons helps to counteract the tensile forces caused by the weight of the bridge and the loads it carries.

Faqs

Circular Prestressing is when we put strong wires in a circle around a structure, like a round tank or bridge. Linear Prestressing is when we put those wires in a line along a structure, like beams or long pieces.

In Circular Prestressing, the strong wires spread out the force equally all around the structure, making it strong in every direction. In Linear Prestressing, the wires make the structure strong in a straight line, like a super-strong backbone.

Circular Prestressing is used for round things, like tanks and bridges that are shaped like circles. Linear Prestressing is used for straight things, like beams and long pieces that need to be very strong.

For Circular Prestressing, we put the strong wires in a circle around the structure and make them very tight. For Linear Prestressing, we put the wires in a straight line along the structure and make them tight too. It makes the structures super strong!

Circular Prestressing makes structures very stable, strong against twisting, and can hold a lot of weight. But it can be a little tricky to build. Linear Prestressing makes structures stronger and less likely to bend, and it’s easier to build. But it works best for straight things and may not be good for curved shapes.