Computer-Aided Manufacturing or CAM is a manufacturing process by using computer software. This computer software makes the process simple and automated.

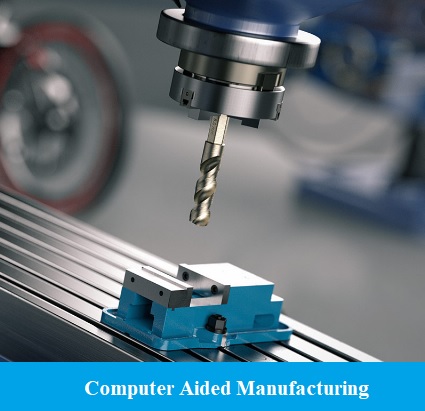

CAM utilized the software and computer-controlled machinery to automate a manufacturing process.

Computer software helps in all phases of manufacturing, including process and production planning schedule, manufacture, quality control, and management.

There are 3 important components of CAM.

- Software.

- A machine such as a CNC machine.

- Post-processing system which gives instructions to machine.

These three parts are stuck along with tons of human labor and skill. It took years building and refining the best manufacturing machinery around. Today, there’s no plan excessively intense for any proficient mechanic shop to deal with.

How CAM Works?

CAM uses computer software to translate drawing and data into detailed instruction. CAM works with CAD to complete the manufacturing process. CAD uses to prepare the drawing while CAM focuses on how to make it. CAM converts the drawing into the list of instructions to complete the manufacturing process.

In simple words, CAM orders the machine how to complete the manufacturing task.

CAM software creates a model for machining by working through several actions, including:

- Checking if the model has any geometrical errors that will effect the manufacturing process.

- Creating a well defined instruction for the model, a set of coordinates the machine will follow during the manufacturing process.

- Setting any needed machine parameters, including cutting speed, voltage, cut/pierce height, etc.

- Configuring nesting where the CAM system will decide the best orientation for a part to maximize machining effectiveness.

Advantages of Computer Aided Manufacturing (CAM)

- CAM automates the manufacturing process.

- CAM makes the manufacturing process very fast.

- CAM reduces error in the manufacturing process.

- It provides greater accuracy and consistency.