Computer Integrated Manufacturing (CIM) is a manufacturing process by uses computer-controlled machinery, automated tool, various computer program, and software.

Computer-integrated manufacturing (CIM) is the manufacturing approach of utilizing PCs to control the whole production process. This integration permits individual processes to trade data with each part. Manufacturing can be quicker and less mistake-prone by the integration of computers. Normally CIM depends on closed-loop control processes based on real-time input from sensors. This process is also called flexible design and manufacturing.

The main purpose of CIM is to accomplish the highest effectiveness, shutting those gaps that hinder productivity and result in the bottom-line taking a hit. Moreover, CIM plays a huge role in gathering relevant, real-time information from the production floor.

It is used to improve efficiency, CIM can monitor the operational performance of vital equipment.

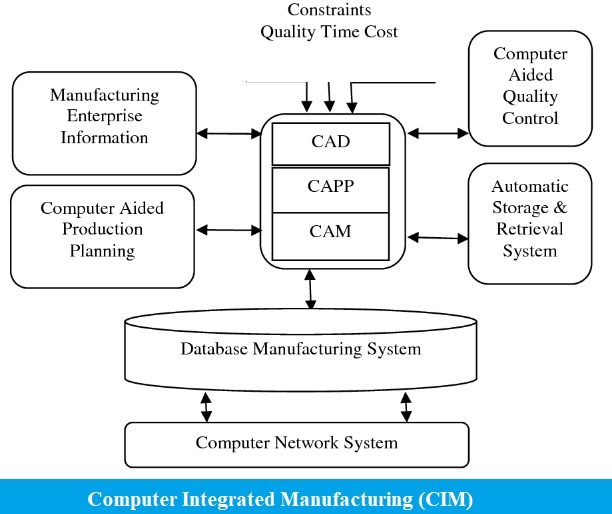

Computer-integrated manufacturing uses various technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) to provide an error-less manufacturing process that decreases manual labor and automates repetitive tasks.

The computer-integrated manufacturing approach enhances the speed of the manufacturing process and uses real-time sensors and closed-loop control processes to automate the manufacturing process. It is widely used in the automobile industries, space sector, etc.

Components of Computer-Aided Manufacturing (CIM):

- Information storage, retrieval, control, and introduction system.

- Real-time sensors for detecting the present status and for adjusting measures.

- Data processing algorithms.

Advantages of Computer-Aided Manufacturing:

- It improves the quality of the product.

- It is cost-effective.

- It saves time.

- CIM reduces errors in the manufacturing process.

- Computer-integrated manufacturing increases the manufacturing process.

- It is more flexible compare to the traditional manufacturing system.