As the name suggests concrete vibrator machine is a mechanical device for creating a vibration in wet concrete. It comes in various shapes and sizes. The concrete vibrator has a different needle-like 25 mm to 90 mm.

The selection of vibrator needle is based on center to center spacing between two or more steel bars. If the spacing between reinforced bars is less than 25 mm then self-compacting concrete can be used.

Table of Contents

Uses of Concrete Vibrator Machine:

The vibrations drive the mixture to liquefy, decreasing the internal friction of the mix components of cement, aggregate, and water. Due to vibration concrete can move freely in whatever form you are placing the concrete. This helps to assure that sufficient concrete gets into every little nook and cranny and eliminates voids. Moreover, the vibrations and liquefication help to permit air bubbles to discharge. There’s a lot of air in the mix when placed, and too much air in the mix permits a less dense mixture and therefore can lead to failures and blemishes. The vibrations assist to bring those air bubbles to the surface where they discharge.

This liquification due to vibration also brings moisture to the surface which allows for easier floating/finishing of the slab, but this is truly more of a byproduct of the vibration process than it is a purpose.

The vibration of concrete is important to attain consolidation of the concrete mix which frequently results in homogenous concrete.

In cases of improper vibration, a fault usually known as honeycombing occurs. This is owing to the fact that the concrete was not fluid enough to “flow” through to all corners.

Self-consolidating concrete is a development that bypasses this requirement for external consolidation. The right balance of viscosity, fluidity, and segregation resistance is what is essential for the success of Self-consolidating concrete.

Types of Concrete Vibrators Machines:

- Immersion or Needle vibrator.

- Extended or Shutter vibrator.

- Surface vibrator.

- Vibrating table.

I have briefly described these 4 vibrators.

1. Immersion or Needle Vibrators:

Immersion or Needle Vibrators are the most commonly used vibrators for concrete pouring. It consists of a steel tube (with one end closed and rounded) having an eccentric vibrating component inside the needle. Steel tube which is known as poker is connected to an electric motor or a diesel engine through a flexible tube. Needle vibrators are available in different sizes based on their needle. It is available from 40 to 100 mm in diameter. The diameter of the poker is decided based on the spacing between the reinforcing bars in the formwork.

Normally, the frequency of vibration varies up to 15000 rpm. Nonetheless, a range between 3000 to 6000 rpm is recommended as a desirable minimum with an acceleration of 4g to 10g.

The typical radius of action of a needle vibrator is 0.50 to 1.0m. However, it would be desirable to immerse the vibrator into concrete at intervals of not more than 600 mm or 7 to 10 times the diameter of the poker.

The period of vibration needed may be of the order of 30 seconds to 2 minutes. The concrete should be placed in layers not greater than 600mm high.

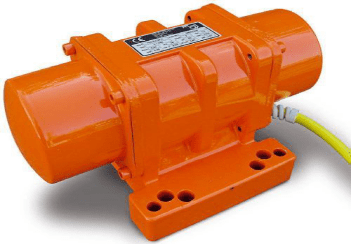

2. External or Shutter Vibrators:

External or Shutter Vibrators are clamped rigidly to the shape work at the pre-determined points so that the form and concrete are vibrated. These types of vibrators consume more power for a given compaction effect than internal vibrators.

These vibrators can compact up to 460 mm from the face but have to be moved from one place to another as concrete pouring progresses. Shutter Vibrators operate at a frequency of 3000 to 9000 rpm at an acceleration of 4g.

The external vibrators are more frequently utilized for pre-casting of thin in-situ sections of such shape and thickness as can not be compacted by Needle Vibrators.

3. Surface Vibrators for Concrete:

Surface Vibrators are placed directly on the wet concrete. This type of vibrator is appropriate for the compaction of shallow elements and should not be used when the depth of concrete to be vibrated is more than 250 mm.

Dry mix concrete can be most effectively compacted with surface vibrators. The surface vibrators most usually used pan vibrators and vibrating screeds. The main application of this type of vibrator is in the compaction of small slabs, not more than 150 mm in thickness, and patching and repair work of pavement slabs. The operating frequency is approximately 4000 rpm at an acceleration of 4g to 9g.

4. Concrete Vibrating Table:

Concrete Vibrating Table consists of a rigidly built steel platform mounted on flexible springs and is driven by an electric motor. The mean frequency of vibration is 4000 rpm at an acceleration of 4g to 7g. The vibrating tables are very efficient in compacting stiff and rough concrete mixes required for the manufacture of precast elements in the factories and test specimens in labs.

How To Choose Best Concrete Vibrator Machine

Choosing the best concrete vibrator machine is important to achieve a smooth and durable finish. Here are some things to think about:

- Decide which type of vibrator you need. Internal vibrators are placed inside the concrete mix, and external vibrators are attached to the surface.

- Consider how the vibrator will be powered. You can choose from electric, battery-operated, or compressed air-powered vibrators.

- The frequency of the vibration is important. A higher frequency usually produces better results, but it can be more expensive.

- The amplitude, or maximum displacement of the vibrator head from its central position, is also important. A larger amplitude can compact a larger area of concrete at once.

- Think about how portable you need the machine to be. Some machines come with wheels or handles to make them easier to move around.

- Vonsider the price of the machine and how it fits into your budget.

These above mentioned factors will help you to choose the best concrete vibrator machine for your project and achieve a smooth and durable finish.