Table of Contents

Introduction of Tunnel Boring Machine

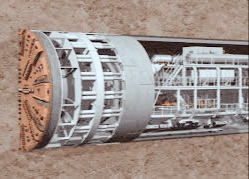

Tunnel boring machine is use to excavate ground for the construction of tunnels. These machine are specially design to excavate the hard soil such as rocks. These types of boring machine can go in higher depth of earth. They have circular cross section to excavate hard soils. These boring machine can also be used for micro-tunneling.

Description

Tunnel boring machines are used for rock drilling and blasting and as an alternative to traditional hand boring machine. Tunnel boring machine has the advantage of limiting disturbance to the surrounding soil and creating smooth tunnel walls. This significantly reduces tunnel lining costs and makes them suitable for urban use.

Tunnel boring machine are expensive to build and can be difficult to transport. The longer the tunnel, the lower the relative cost of the tunneling machine compared to drilling and blasting methods.

However, drilling and blasting are still the preferred method when dealing with heavily fractured and sheared rock formations.

Types of Tunnel Boring Machine

Normally two types of tunnel boring machines are used to perform boring operation.

- Hard Rock Tunnel Boring Machine

- Soft Rock Tunnel Boring Machine

Let’s know more about these two types of tunnel boring machines.

1. Hard Rock Tunnel Boring Machine

Shielded boring machine and open boring machines are used to excavate hard rocky soils. A special cutting blade is used to cut hard rocks. Cutting discs create compressive stress fractures in the rock and break up tunnel chips. Excavated rock is conveyed through openings in the cutter head to a belt conveyor that carries it through the machine to a system of conveyor belts.

An open type tunnel boring machine has no shield, leaving the area behind the cutter head open for rock support. For tunneling, the machine uses a gripper system that presses against the walls of the tunnel. A machine like the Wirth machine can only be steered without a steering wheel. Other machines can be steered. Grabbing it pushes the machine forward. At the end of the cycle, the grapple and power cylinder retract and the hind legs are lowered while the machine moves forward. The grippers are then re-engaged and the rear legs are raised for the next digging cycle.

Open type machines or main beams do not install concrete segments behind them. Instead, rocks are held in place with ground support methods such as ring beams, rock bolts, shotcrete, steel bands, ring steel, wire he mesh.

Shielded tunnel boring machine can be used on broken rocks. Behind the machine are concrete segments that support the walls of the tunnel. The Double Shield tunnel boring machine has two modes. On stable ground, grab the tunnel wall and move forward. In unstable and rough terrain, thrust is shifted to the thrust cylinder pushing the tunnel segment behind the machine. This prevents shear forces from acting on the fragile tunnel walls. The Single Shield tunnel boring machine works similarly, but is only used on loose ground as it can only be pushed against concrete segments.

2. Soft Rock Tunnel Boring Machine

Soft rock tunnel boring machine is used to cut soft soil. It is easy to cut soft soil compare hard soil. These types of machine is designed to perform work quickly. These machines are single shielded. Soft rock tunnel boring machine used thrust cylinders to push concrete segments forward.

Cutter heads use a combination of tungsten carbide cutting tips, carbide disc cutters, drag picks, and/or hard rock disc cutters. Pressure is maintained by controlling the topsoil extraction rate and forward speed. Additives such as bentonite, polymers and foams can be injected in front of the surface to improve soil stability. Additives can be injected into the cutter head to keep it sticky enough to maintain pressure and form a plug within the auger to restrict water flow.

Tunnel boring machine perform operation quickly. It reduces the need for large numbers of workers working under high pressure, but a caisson system can form in the cutting head of the Mud Shield Tunnel Boring Machine. Workers entering this space for inspection, maintenance or repair must be medically submersible and trained to operate locks.

Sum Up

Tunnels are the future of transportation. Tunnels boring machines make fast operation and reduce manpower.

I hope you enjoyed my article on tunnel boring machines. Thanks for reading.