In this post you will learn about the defects in concrete structures, their causes and repairs.

There can be different types of defects that can occur in concrete structures it may be crazing, cracking, blistering, dusting, delamination, efflorescence, scaling, spalling, and Curling. These defects can be due to various reasons or causes.

Table of Contents

Causes Of Defects In Concrete Structures:

Causes of defects in concrete structures can be broadly classified as:

- Structural inadequacy resulting from errors in, loading criteria, design, unexpected overloading, etc.

- Structural inadequacy due to construction defects.

- Harm due to fire, floods, earthquakes, cyclones, etc.

- Harm due to marine environments.

- Harm due to the abrasion of granular materials.

- Due to the physical characteristics movement of concrete.

(a) Structural Defects Because of Design and Detailing:

In this case, the design is required to be reviewed in detail, and rechecking measures worked out by the design team. After this is done the methods of carrying out the fortification measures will be similar to those arising out of other defects.

(B) Structural Inadequacy Due to Construction Defects:

Faulty construction methods form the largest segment of the source of strain to the beams. Such defects can be broadly divided as follows:

- Fault due to the quality of raw materials.

- Designed concrete mix non-adoption.

- Use of faulty construction plant for producing, transporting, and placing the concrete.

- Faulty workmanship.

- Poor quality detailing.

It is very important to choose a good type of cement for the concrete going into the structure under consideration. Ordinary Portland cement is the most common of all cement. Provided the quality of cement satisfies the applicable standard specifications, at the time of use, generally, no problem is encountered in respect of ordinary Portland cement.

Where the concrete is exposed to a violent environment, it may be necessary to use a particular type of cement, such as sulfate resisting Portland cement, blast furnace slag cement, low C3A cement.

The quality of aggregates, particularly with respect to alkali-aggregate reaction, needs to be taken into account, luckily cases of defects/failures attributed to the alkali-aggregate reaction are very low.

The use of water containing salt for making concrete can also contribute to the decay of the concrete.

The design of the concrete mix can be adequately carried out using a wide variety of aggregates. A logical continuity of grading of aggregates should be ensured.

Extra use of water in the concrete mix is the largest single source of weakness.

The accuracy of weighing the different components is very much dependent on the quality of the weigh batching system, available. Spring-loaded dials of the weigh batchers contribute toward extra variability in the quality of weigh-batched concrete.

Other characteristics that add to ill workmanship include segregation, improper placement, inadequate or extra vibration leakage of mortar through shuttering joints, inadequate concrete cover, insufficient curing, etc.

Perfect detailing of reinforcement, including sufficient cover, is essential to ensure the successful placement of concrete. poor detailing results in clogging of reinforcement to such a limit that concrete just cannot be placed and compacted properly, even if the concrete is workable.

Detailing of reinforcement should be based on an actual valuing of how the concrete placement and compaction are going to be carried out.

Different Factors that Lead to Poor Design Detailing:

- Corners Re-entrants.

- Sudden changes in section.

- Not proper joint detailing.

- Limits of deflection.

- Inadequate detailed drips and scuppers.

- Improper drainage.

- Inadequate detailing of expansion joints.

Types Of Defects In Cocrete Structures And Their Prevention:

Different types of defects which can be observed in hardened concrete surface and their prevention methods are explained here:

1. Cracking:

Cracks are formed in concrete because of different reasons but when these cracks are very deep, it is not safe to use that concrete structure. Different reasons for cracking are not proper mix design, insufficient curing, a gap of expansion and contraction joints, use of high slump concrete mix, not suitable sub-grade, etc.

To stop cracking, use a low water-cement ratio, and maximize the coarse aggregate in the concrete mix, admixtures containing CaCl2 must be avoided. The surface should be prevented against the quick evaporation of moisture content. Loads must be applied on the concrete surface only after getting their maximum strength.

2. Crazing:

Crazing also called pattern cracking or map cracking, is the development of closely spaced shallow cracks in an uneven manner. Crazing occurs due to the fast hardening of the top surface of concrete due to high temperatures or if the mix contains extra water content or due to insufficient curing.

Pattern cracking can be avoided by proper curing, by dampening the sub-grade to counter absorption of water from concrete, by providing protection to the surface from quick temperature change.

3. Blistering:

Blistering is the development of hollow bumps of various sizes on the concrete surface due to entrapped air under the finished concrete surface. It may cause due to extreme vibration of concrete mix or presence of excess entrapped air in the mix or improper finishing. Extreme evaporation of water on the upper surface of the concrete will also cause blistering.

It can be prevented by using a fine proportion of ingredients in the concrete mix, covering the upper surface which reduces evaporation, and using appropriate techniques for placing and finishing.

4. Delamination:

Delamination is also the same as blistering. In this case, also, the top surface of concrete gets split from the underlying concrete. Hardening of the upper layer of concrete before the hardening of underlying concrete will lead to delamination. It is due to the water and air bleeding from underlying concrete being struck between these two surfaces, hence space will be formed.

Like blistering, delamination can also be stopped by using proper finishing techniques. It is finer to start finishing after the bleeding process has run its course.

5. Dusting:

Dusting also called chalking is the development of fine and loose powdered concrete on the hardened concrete by deterioration. This happens due to the existence of an excess amount of water in concrete. It causes bleeding of water from concrete, with this fine particle like cement or sand will rise to the top and consequent overtired causes dust at the top surface.

To keep away dusting, use a low slump concrete mix to obtain a hard concrete surface with good wear resistance. Use water-reducing admixtures to obtain sufficient slump. It is also suggested to use better finishing techniques and finishing should be started after removing the bleed water from the concrete surface.

6. Curling:

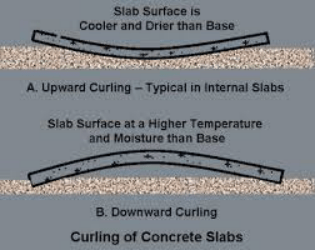

When a concrete slab is twisted into a curved shape by upward or downward movement of edges or corners, it is called curling. It happens mainly due to the dissimilarity in moisture content or temperature between the slab surface (top) and slab base (bottom).

The curling of the concrete slab may be downward curling or upward curling. When the upper surface is dried and cooled before the bottom surface, it begins to contract and upward curling takes place. When the bottom surface is dehydrated and cooled due to high temperature and high moisture content, it will shrink before the top surface and downward curling occurs.

To prevent curling, use a small shrink concrete mix, provide control joints, provide heavy reinforcement at edges or provide edges with good thickness.

7. Efflorescence:

Efflorescence is the formation of the accumulation of salts on the concrete surface. Formed salts are generally white in color. It is because of the presence of soluble salts in the water which is used in manufacturing concrete mix.

When concrete is hardening, these soluble salts get heave to the top surface by hydrostatic pressure, and after absolute drying, salt deposits are formed on the surface.

It can be stopped by using clean and pure water for mixing, using chemically unproductive aggregates, etc. And confirm that cement should not contain alkalis more than 1% of its weight.

8. Scaling and Spalling:

Scaling and spalling, in both cases concrete surface gets decayed and flaking of concrete occurs. The main cause of this type of case is the perforation of water through the concrete surface. This makes steel gets corroded and spalling or scaling may occur.

Some other causes are the use of the non-air entrained concrete mix, poor curing and use of low strength concrete, etc. This type of defect can be stopped by, using well-designed concrete mixes, by adjoin air entrainment admixtures, proper finishing and curing, providing a good slope to drain water coming onto the surface, etc.

How To Repair Defects In Concrete Structures

The repair process for concrete defects depends on the type and severity of the defect.

Here are some general steps that can be taken for repairing common concrete defects:

- Identify the defect: It is important to identify the type and extent of the defect before proceeding with repairs. Common concrete defects include cracks, spalling, scaling, and settlement.

- Prepare the surface: Before repairing any defects, the surface should be cleaned thoroughly to remove any loose debris or contaminants. This can be done using a wire brush or a pressure washer.

- Repair the defect: The repair method will depend on the type of defect. For cracks, a concrete crack filler can be used to fill the gap. For spalling or scaling, the damaged concrete can be removed using a chisel or a grinder, and a new layer of concrete can be applied. For settlement, the concrete can be lifted and leveled using mudjacking or slabjacking.

- Cure the repair: After the repair has been made, the concrete should be allowed to cure for the recommended amount of time. This typically involves keeping the surface moist and protected from the elements.

- Seal the surface: To prevent future damage, it is important to seal the concrete surface with a concrete sealer. This will help to protect the concrete from water and other elements that can cause further damage.

If defects is sever, I would recommend to consult with a professional concrete contractor for repairs.

Conclusion:

These were the defects in concrete structures. These defects in concrete structures reduce the long-term stability of the structure. These defects should address asap.