Post-concreting defects of structures are defects that are visible after the formwork has been removed.

We will discuss the repair of these defects after concrete placement, the materials, equipment and repair methods required.

Table of Contents

Key Important Things to be Remembered for Repair of Post Concreting Defects

There are four important things that should be considered while repairing defects.

1. Convenience:

The longer the repair takes, the more work has to be done and the less likely it is to be done properly.

2. Cleanliness:

When repairing concrete, care should be taken to remove dirt and dust that prevent the repair concrete from adhering to the base concrete.

3. Proper Technique:

Proper technique and tools are essential for repairing damaged concrete.

4. Material Durability

Repairs should be done while the concrete is still very young. This makes the repair very similar to the original concrete repair. All areas to be repaired should be free of loose dirt and dust to avoid trying to glue the repair with dust particles. Persons responsible for complete repairs should know what actions are required. Repairing concrete requires more skill than laying concrete in the first place, so you should be trained in the tasks involved.

Materials Used to Repair Defects

Before starting the repair, the operator should have all the necessary materials and equipment.

1. Portland Cement and White Portland Cement:

Repairs are usually made with a high concentration of cement, so the finished repair will appear darker than the original concrete. White Portland cement will help lighten the colors.

2. Aggregate and Sand:

We recommend using the same mix as the original, with limestone (which also helps lighten the color).

3. Measuring liquid:

Usually water containing polymeric materials such as styrene-butadiene rubber (SBR), polyvinyl acetate (PVA), and acrylic. They improve the cohesion and adhesion of repairs to the original concrete and improve physical properties such as tightness and elasticity to hardened concrete.

The above materials can be used to repair cracks, but epoxy resin or polyester resin may be required depending on the width of the crack.

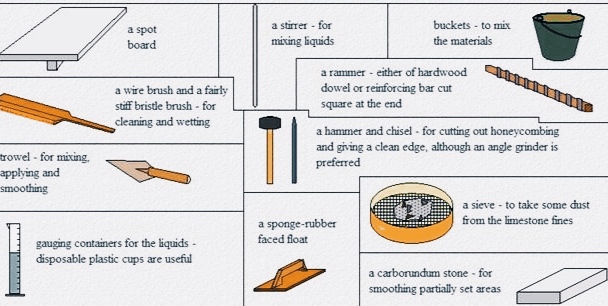

Selection of Correct Equipment to Repair the Defected Structure

The diagram below shows the typical equipment required for concrete repair.

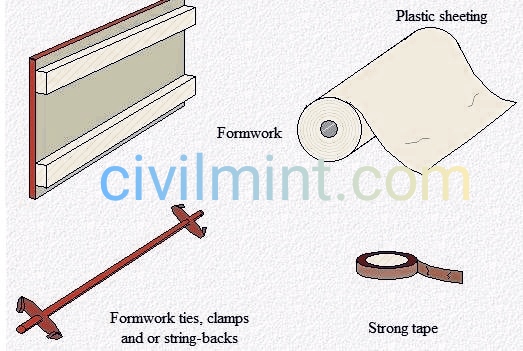

If the repair is extensive, formwork, formwork ties or formwork clips and straps may be required.

All repairs must be allowed to harden, so you will need to have plastic sheets and tape ready to stick to the concrete.

How to Repair Honeycombed Concrete

The techniques used to repair honeycomb concrete are common to other defects and should replace the loss of mortar near the surface.The step-by-step process to repair honeycomb concrete is as follows:

- Scrape off the honeycomb concrete with a hammer and a chisel.

- Then brush to remove dust.

- Prepare replacement concrete. A rule of thumb for this is to use a 1:2 combination of cement and limestone fines. The cement is an equal mix of Portland cement and white cement. Gauge fluid can contain equal amounts of water and polymer, but water alone is sufficient for less mature repairs.

- The mixture should be added so that it is just wet. A compound with low slump is required to prevent misalignment, especially in vertical planes.

- Trowel the replacement concrete into the cavity.

- For a small repair like this, using a vibrator is impractical, so use a stick to compact the concrete and re-smooth it with a trowel.

- For concrete repairs, place a sheet of plastic over it and tape it in place to cure.

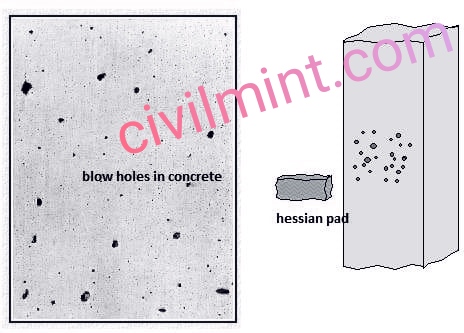

How to Repair Blow Holes in Concrete Structure

A technique called “bagging” is used to repair excess voids in the concrete surface. In this technique, cement paste is rubbed into the holes with a jute pad. No further vibration or compression is required.The repair mix is usually a 1:4 mixture of cement and fine sand (silver sand is often used) with just enough water to make a very hard paste.

This treatment is most effective immediately after the formwork is removed, preferably the day after the concrete is poured. A carborundum stone is used to polish the surface to expose other blowholes near the surface. Sanding the surface exposes more unhydrated cement particles that can bind with the restorative work.

Put the mixture in a burlap cloth and rub it over the concrete surface in a circular motion, filling the holes and coating the surface with a fine cement paste.

How to Repair Cracks in Post Concrete Structure

Cracks should always be reported to the appropriate regulatory agency. Minor cracking is common in most concrete structures, but may be negligible depending on the severity of the cracking. Of course, cracks can also indicate that something is wrong.

Cracks in floor slabs can usually be filled with cement paste, since the main function of deck zone concrete is to protect the reinforcing bars from corrosion. This is particularly satisfactory when the panel has a surface coating that hides cracks and provides additional protection. Cracks in walls that cannot be repaired using this method should be repaired using other methods.

First, the crack should be analyzed to determine if it is under tension. Live cracks are more likely to grow over time, indicating the need to form flexible joints.Dead cracks can be injected with resin.

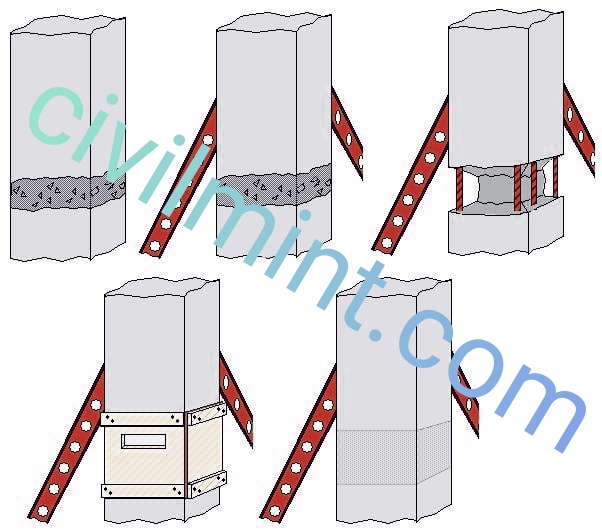

How to Repair Structural Defects Due to Deep Honeycomb

If the comb is deep, or if it passes through a section as it happens occasionally, the concrete will need to be removed and the entire section re-poured. must be supported by braces. After that, the defective area can be divided. This usually requires more than a hammer such as a chisel and a chisel. A pneumatic hammer as shown in the photo below.

After the honeycomb concrete is removed and the area is covered with dust, the formwork can be assembled. Special holes (sometimes called mailboxes or bird mouths) must be drilled in the formwork so that the concrete can be placed while the formwork is in place.

The repair concrete mix can be the same mix used in the original pour. Concrete is thrown in from the opening and vibrated with a small vibrator. The repair may also require external vibration. Make sure the entire cavity is filled when you pour the final concrete.The formwork must be left for 24 hours before it can be removed.