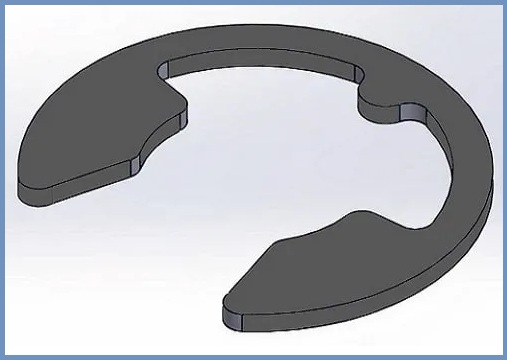

E clip is a type of circlip. This type of circlip is also called ring clip or E-ring. E clip is one of the most popular types of external circlips. This type of circlip looks like the E letter of English that is why it is called E clip. It is open from one side.

Most of the circlip comes in C shape. This design allows it to expand when mounted around the shaft and to compress when mounted in a hole. E clips are normally used for devices such as locking mechanisms and car engines. These are large snap rings that hold the component to the shaft when placed in the slot.

Standard retaining rings are available in internal and external versions. The internal snap ring fits into the groove in the hole and the external snap ring is designed to fit snugly into the groove on the outside of the shaft or rod. These are used to replace the need for mechanical fasteners and typically reduce the weight of the assembly. They usually offer a longer lifespan.

Another advantage of using the eclipse is that it can be easily pushed into the machined groove without the need for special tools. You don’t even need a circular shaft. In general, these devices offer superior functionality over other fasteners, eliminating the need for threading, tapping, or other machining operations.

The three prongs of the ring contact the bottom of the groove and form a shoulder for effective assembly retention. Unlike snap rings, which must be slid along the shaft or rod axis to remove, the e-ring can be easily removed from the side without moving the axis.

A typical size for an E clip is the maximum diameter of the groove in which the clip is designed. Other important dimensions are mouth width and free diameter. The neck size is the size of the opening and the free diameter is the outermost diameter. Both of these are accurately measured with a relaxed ring clip.

The E clips are available in a variety of materials such as copper, stainless steel, carbon steel, and alloy steel, depending on the corrosion resistance needs of the application. These components are commonly used in machines ranging from simple hand tools to complex aircraft. It is also commonly used in transportation and rail systems due to its ease of installation and removal.

Overall, there are different E clip sizes and types depending on the application. Correct dimensions are important when it comes to retaining rings. The components should be tightened to prevent loosening. A potential drawback of E clips is that they can limit the capacity to hold the load, depending on your requirements. However, overtightening can damage the shaft and affect the performance of the assembly.