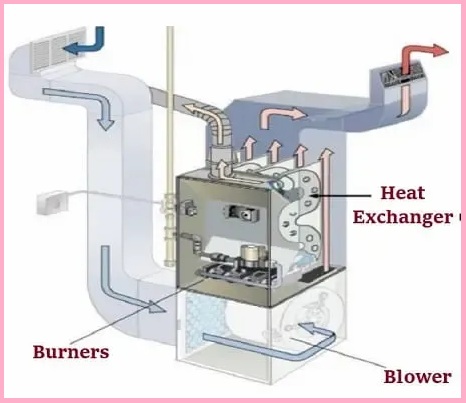

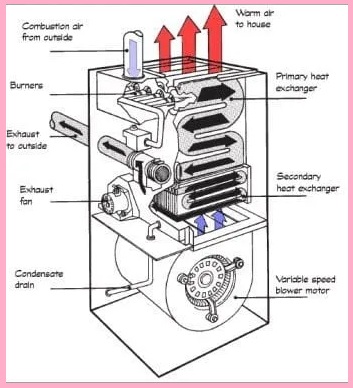

A furnace Heat Exchanger is a thin metal shield standing between the combustion chamber and the blower. As the combustion chamber adds heat to the heat exchanger, heat or heat energy is transferred to the air blowing across the surface. This air contains no exhaust gas and is directed to the duct system to provide heat to the house. In order to function properly and prevent combustible gases from escaping, the heat exchanger must be completely sealed.

The heat exchanger of the furnace is a component of the fire that is responsible for maintaining the separation of the combustion process and air (oxygen) for proper breathing. Stopping carbon monoxide poisoning is very important. Gases generated during combustion (such as carbon monoxide) are harmful to your health. Therefore, the heat exchanger should include an airtight seal to prevent combustion gas from entering the house.

Table of Contents

Working of Furnace Heat Exchanger

The operating principle of the furnace heat exchanger is to transmit the heat produced in the combustion chamber to the outside of the device and blow it into the entire heating system of the fireplace through the blower. Basically, the process ends with the following three steps. For example, consider a gasoline-powered HVAC system which is one of the most well-known residential systems.

- First, the kiln needs heat to start the firing process. The hot flue gas from the combustion process enters the heat exchanger chamber, where it heats the metal wall.

- After this process, the return duct draws cold air from the house and blows it out of the heat exchanger. Cold air turns into hot air as it passes through heat exchangers, heating walls, and various rooms in the house. This process maintains the separation between the breathing air and the combustion gas.

- The gas produced during the combustion process exits the heat exchanger and exits the vents outside the house. The operating modes of high-performance condensed stoves are slightly different. In such a stove, the gas passes through a second heat exchanger and absorbs additional heat for home use.

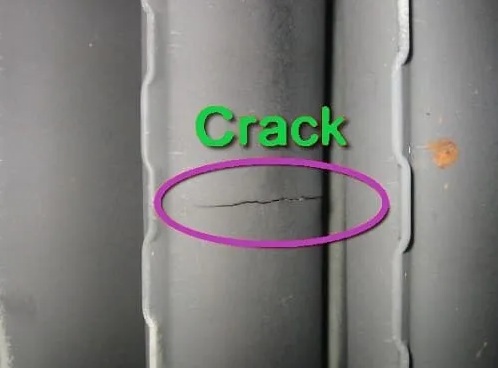

Cracked Heat Exchanger

Cracked heat exchangers are dangerous and can cause furnace problems. If the heat exchanger cracks, unburned gases such as nitrous oxide, sulfur dioxide, and carbon monoxide can escape and enter the house. Too high levels of carbon monoxide in the home can cause serious health problems such as nausea and death.

Homeowners want to know what to do to avoid problems in the first place when they learn about the dangers of cracked heat exchangers. Today, in this article, I’ll show you how to prevent cracks in the heat exchanger inside the furnace.

Symptoms of a Cracked Furnace Heat Exchanger

- Bad heating.

- Existence of CO.

- Offensive or unpleasant odor.

- Hearable noise.

- Soot formation or discolored metal.

- Changes in the flame pattern.

- Corrosion and cracks.

Benefits of a Furnace Heat Exchanger

The main advantage of a fully functional furnace heat exchanger is that it helps protect the occupants of the home from combustion by-products. Mixing dangerous smoke with the air-breathing indoors can be fatal. This is why it is so important (and sometimes required by law) to install carbon monoxide alarms in every home with a fuel burner. For this reason, it is also important to maintain the heat exchanger of the stove.