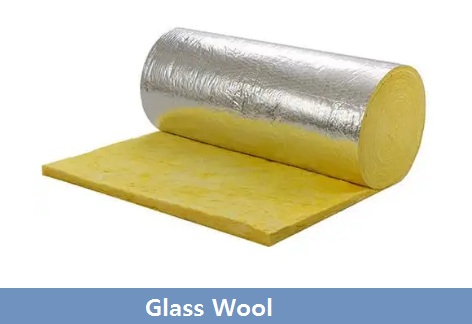

Glass Wool is an insulating material made from glass fiber called borosilicate glass. These glass fibers are arranged in a well-defined manner using a binder into a texture similar to that of wool. It contains silica sand, recycled glass, and fixing agents which form a perfect combination in order to provide good insulation and coating for the houses.

The main characteristic of glass wool is to save energy by efficiently reducing the rate of transfer of heat through the components of the building. Glass wool is used in refrigerators to provide resistivity against corrosion by keeping the exposed surface of a refrigerated system above the dew point.

Table of Contents

Manufacturing Process of Glass Wool

Glass wool is mainly made of sand and recycled glass. Excellent thermal properties help to conserve energy and combat climate change.

Step by step manufacturing process of glass wool is described below.

1. Batching

The main components of glass wool are sand, soda ash, limestone, and recycled glass. It is stored in silos. The process begins with weighing, mixing, and pouring the components into the oven.

2. Melting

The mixed components are then melted in an electric gas furnace above 1400°C.

3. Fiberizing

The liquid glass obtained from the kiln later enters the fiber-making machine through a feeder, where it is forced through small holes by a centrifugal spinner to form fibers. These fibers are sprayed with a binder and formed into a blanket.

4. Forming

The textile blanket is passed through a drying oven where it is pressed to the desired thickness.

5. Cutting

After obtaining the final thickness, the blanket is cut to the required width. Cuts from cuts are ultimately recycled to avoid waste.

6. Packing

Before wrapping, the mat is rolled out using a sheet machine installed at the end of the line. For boards, a laying machine is provided.

7. Palletization

If necessary, the glass wool can be compressed up to 10 times the palletizing volume. The glass rolls obtained in this process total 36 rolls, which can be put on one pallet.

Benefits of Glass Wool

- It is thermal insulated material.

- It is a sound-insulating material.

- Glass wool is not much expensive material.

- It is easily available.

- Transportation is easy due to its lightweight.