Today I will discuss about very innovative material in construction industry called Glass Reinforced Plastic.

Table of Contents

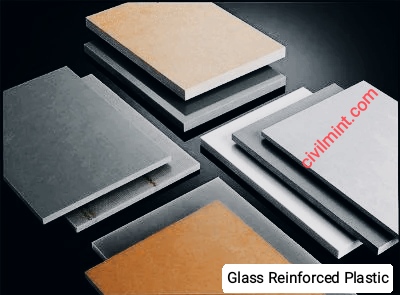

What Is Glass Reinforced Plastic?

Glass Reinforced Plastic is a composite material made of of a plastic resin matrix reinforced with fine fibers of glass.

Glass Reinforced Plastic (GRP) also called as Fiberglass Reinforced Plastic (FRP). Sometimes it is known as Glass Fiber Reinforced Plastic.

The fibers are weaved into a cloth and mixed with resin to make a tough and long-lasting material.

Properties Of GRP

Glass Reinforced Plastic (GRP) is a material that boasts a unique combination of properties.

It is lightweight but strong and rigid, making it suitable for applications where weight is a concern, such as in the manufacture of boats, aircraft and automotive components.

GRP is also highly resistant to corrosion and chemicals, making it an ideal material for use in harsh environments such as chemical processing plants, water treatment plants and offshore structures.

The material can be molded into complex shapes using a variety of techniques, such as hand-lay-up, spray-up, and vacuum infusion.

This makes it a versatile material that can be used to make a wide range of products, from small components to large structures.

Uses of Glass Reinforced Plastic

- Construction: GRP is widely used in the construction industry due to its strength, durability, and resistance to corrosion. It is used in the construction of bridges, buildings, and infrastructure.

- Transportation: GRP is used in the transportation industry to manufacture lightweight components that improve fuel efficiency. It is used in the production of boats, cars, and airplanes.

- Aerospace: GRP is widely used in the aerospace industry due to its lightweight and high strength-to-weight ratio. It is used in the manufacture of aircraft parts, such as wings, fuselage sections, and engine components.

- Sports and Recreation: GRP is used in the manufacture of sports equipment, such as hockey sticks, fishing rods, and golf clubs. It is also used in the construction of swimming pools, water slides, and amusement park rides.

- Electrical and Electronics: GRP is used in the electrical and electronics industry to manufacture insulators, switchgear components, and electrical enclosures.

Advantages of Glass Reinforced Plastic

- Lightweight: GRP is a lightweight material that has a high strength-to-weight ratio. This makes it an ideal choice for applications where weight is a critical factor, such as in the aerospace and transportation industries.

- High Strength: GRP has a high tensile strength, which makes it strong and durable. It is stronger than many other materials, including steel and aluminum.

- Corrosion Resistance: GRP is highly resistant to corrosion, which makes it an ideal choice for applications where exposure to corrosive environments is a concern.

- Design Flexibility: GRP can be molded into complex shapes and designs, which makes it an ideal choice for applications where aesthetics are important.

- Low Maintenance: GRP requires little maintenance and can withstand exposure to harsh weather conditions without deteriorating.

Disadvantages of Glass Reinforced Plastic

- Cost: GRP can be more expensive than some other materials, such as steel and aluminum.

- Brittle: GRP can be brittle and prone to cracking under stress, especially if it is not properly reinforced.

- Flammability: GRP is flammable and can release toxic fumes when burned.

- Environmental Concerns: GRP is not biodegradable and can pose a disposal problem at the end of its useful life.

- Surface Finish: GRP can have an uneven surface finish, which can be difficult to paint or coat.

My Opinion On GRP

Glass Reinforced Plastic is a versatile material that has a wide range of uses in many industries.

Its unique properties, such as its lightweight, high strength, and corrosion resistance, make it an ideal choice for many applications.

However, it does have some disadvantages, such as its cost and environmental concerns, that should be considered before choosing it for a particular application.