Table of Contents

Definition

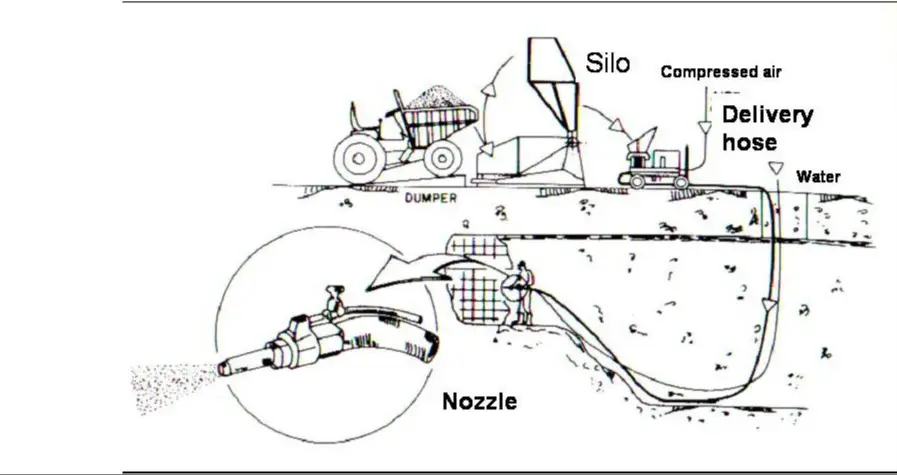

Guniting is the process of applying mortar or concrete under pneumatic pressure through a cement gun. This method results in a highly strong concrete and a superior bond.

What Is Guniting?

The gunite mixture is comprised of cement and sand and is conveyed through the gun equipment. Water is then added at a high velocity through a nozzle. The mixture is pneumatically forced onto a backing surface, where it strikes the surface to be protected or repaired at a high velocity.

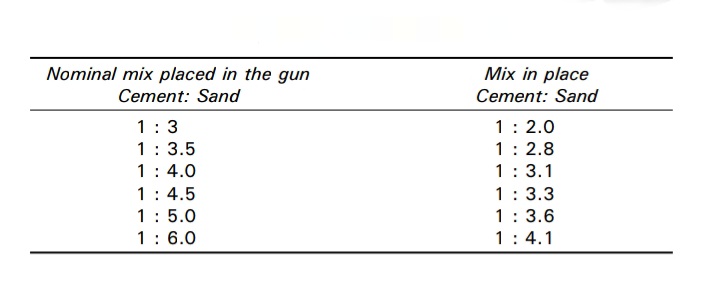

During the process, the coarser particles rebound from the surface, leaving behind an excellent bond coat of fine grout that is in close contact with the backing surface. The successive layers of guniting are cushioned by a thin layer of grout that builds up and acts as a cushion, reducing the percentage rebound. It is important to note that the material deposited on the backing surface is different from the mix leaving the gun due to the higher concentration of coarse materials in the rebound material.

Fig. 1 shows the proportions in place

for various gunite mixes for optimum nozzle velocity.

The economy is most affected by rebound in the application of gunite. Below are listed approximate values of rebound for different working conditions.

- Basements – 30%

- Vertical walls – 40%

- Overhead slabs – 50%

- Beam sides and bottoms – 55%

- Columns – 65%

Proces Of Guniting

Guniting is a process where the impact force of a jet compacts the material, and it is preferred to use a dry mix for this technique. This dry mix can support itself without sagging, even when applied in vertical or overhead applications. The layers applied during guniting are typically 40-50 mm thick.

After the initial layer is applied and has set, loose material and laitance are removed by hammer to locate any dummy areas that may result from lack of bond or rebound pockets. These pockets are then cut and replaced during the placement of the subsequent layer.

A well-compacted gunite that is allowed to cure for 28 days can have a compressive strength as high as 42 N/mm2. The average unit weight of gunite is 2300 kg/m3, and curing is done for seven days.

Precautions In Guniting Process

- Maintain the appropriate air and water pressure levels to ensure a consistent application and avoid a spotty appearance. Keep the water pressure 0.45-0.675 N/mm2 higher than the air pressure.

- Thoroughly clean the backing surface before guniting. For concrete and masonry surfaces, follow cleaning with wetting and damp drying.

- When guniting walls, start from the bottom. Ensure that the first layer of gunite completely embeds the reinforcement, and maintain a distance of 0.6-15m between the nozzle and backing surface. Do not exceed a nozzle velocity of 140 m/s, as higher velocities can result in a porous mass of lower strength due to interference with rebound material.

- For repairing structures, apply a gunite layer with a thickness of at least 40 mm.

- Do not reuse rebound material.

Advantages

- Guniting is a highly versatile process that allows structures of any shape, such as undulating, spherical, or curved, to be constructed. It finds its use in various applications, including the construction of dams, reservoirs, bridges, pipelines, and canals, as well as in the construction of swimming pools, artificial caves, waterfalls, tunnels, slope protection, refractory works, and many repair works.

- The crew can instantly adjust the water content while carrying out the spraying procedure with guniting, as it allows for the control of water as it is added to the mix at the nozzle. This results in either a wet or dry mix depending on the demand.

- The dry-mix shotcrete or guniting mix can be prepared quickly compared to the wet shotcrete process, making it more suitable for overhead applications. In contrast, a wet mix would be problematic in situations where sagging, sticking, or segregation could occur.

- It is recommended to use the dry-mix shotcrete process for smaller works such as filling cracks, thin linings or coatings, or for very fine treatments, instead of the wet-mix shotcrete process.

- Guniting is an excellent choice for work types where unexpected stoppages may occur. Whereas wet-mix shotcrete would be wasteful in such situations, guniting offers the advantage of not being affected by unexpected stoppages.

Disadvantages

- Proper control over pressure, water addition at the nozzle, and the application of high-quality mix on the surface during the guniting process require skilled and experienced labor. The operator who performs the operation plays a significant role in ensuring the quality of guniting.

- The guniting process experiences rebound, which occurs when mix ingredients sprayed on the surface bounce off and fall on the ground. This phenomenon is more common in the dry-mix process of guniting as compared to the wet-mix shotcrete process.

Uses Of Guniting

Gunite is a versatile construction material that can be used to create thin sections such as folded plates, shells, and thin walls.

It is also commonly used for various applications such as linings for tunnels and swimming pools, repairing concrete damaged by fire, earthquake, or chemicals, and strengthening buildings, bridges, and jetties.

Gunite can be used for stabilizing rocks and earth slopes, as well as providing protective coatings over prestressing wires and steel pipes.

From an architectural perspective, gunite can also be used to create rough surface textures. Pneumatic guniting is a technique used for applying gunite to refractory castables.