Table of Contents

What is Hydraulic Press?

A hydraulic press is a mechanical device based on “Pascal’s Law”, which means that in a closed system the same amount of pressure is applied in all directions. Here it is true that a change in pressure at one point in a closed system will change the same pressure intensity at another point in the same system.

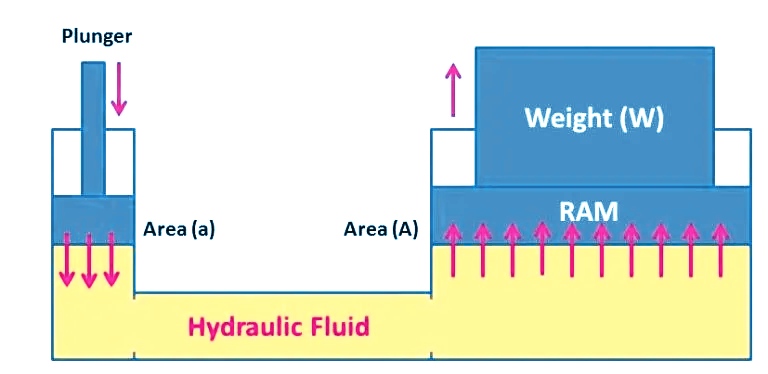

Hydraulic presses can produce large forces with little effort. A hydraulic press assembly has two main parts, one called the ram and the other called the piston. The plunger acts as the output medium and the plunger provides the input. Hydraulic fluid is filled in a closed container between the tappet and plunger and is responsible for the entire function, including power and pressure transmission. In reality, both the piston and tappet have different areas. Where ‘A’ is the piston area and ‘a’ is the piston area, the mechanical advantage of the system is equal to A/a. This is the ratio of ram area to ram area. Pressure is defined as force per unit area, so if F is the force applied to the ram and W is the load stroke through the ram, then Pascal’s law gives the pressure:

P = F/a = W/A or W = F (A/a)

The above relationship can be used in some applications where large forces can be easily generated by adjusting the ram and piston areas.

How Does Hydraulic Press Work?

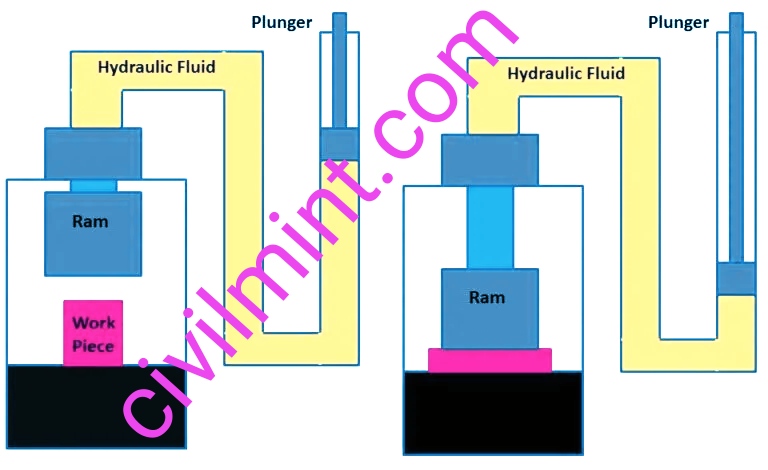

Generally several tappets are assembled together. The number of stamps used depends on your workload. In a hydraulic press, multiple small rams are preferred over a single large ram to control thrust, as smaller sizes are easier to control thrust than larger ones.

In press assembly, one side/table is always stationary and the other is moved by applying ram force and remains stationary in between as a free side pressing process. The ram is actuated by hydraulic oil pressure. High pressure liquids are supplied by pumps and hydraulic accumulators.

A hydraulic accumulator serves as a connection point between the pump and the cylinder. Hydraulic accumulators store high pressure fluid when the press is at rest. Hydraulic presses are used when the operation requires high thrust.

Applications of Hydraulic Press

- Hydraulic presses are primarily used in industries where large metal objects are converted into thin sheets by applying compressive force.

- Sheet metal processing including drawing, deep drawing, punching and stamping.

- Shredding of junk and junk cars.

- The packaging industry.

- In geology, tungsten carbide-coated hydraulic presses are used in the rock crushing stage to prepare samples for geochemical analysis.