Table of Contents

What is Hydraulic Accumulator?

A hydraulic accumulator is a mechanical device used in hydraulic applications. It acts as an intermediate device between hydraulic oil supply lines from pumps to required machines such as hydraulic jacks, hydraulic presses, and hydraulic cranes.

Temporary storage of hydraulic fluid under pressure when the machine is in ideal condition. Some hydraulic machines require high pressure only for short periods of time, and some require high pressure only for the time they need to work, so this is where the hydraulic accumulator comes into play.

Store pressurized hydraulic fluid at the optimum time and supply it to the machine when it is needed. Pumps continuously supply hydraulic fluid that is not always needed. This is why hydraulic accumulators balance the demand and supply of hydraulic fluid.

A small pump can use a hydraulic accumulator to do the same job, which is its main advantage. The maximum amount of hydraulic energy that a hydraulic accumulator can store is called the capacity of the accumulator.

How does it Work?

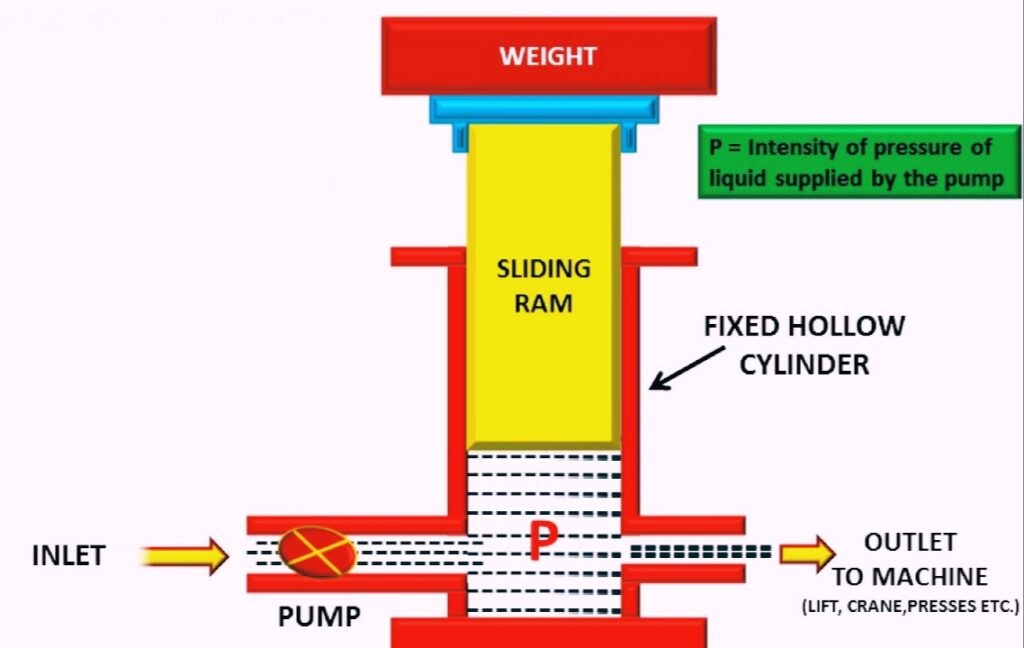

A simple hydraulic accumulator consists of a cylinder with hydraulic fluid inlet and outlet ports, the inlet is connected to the pump and the outlet is connected to the working machine. A cylinder consists of a ram that reciprocates within the cylinder, with a weight on top of the ram. Ram and cylinder placement should be vertical.

The pump continuously supplies hydraulic fluid to the work machine through an accumulator. The outlet is closed when there is no hydraulic oil demand. This time the continuous supply from the pump causes the ram/plunger to rise to extremes or gradually until the exit opens.

This process helps to store hydraulic energy in the accumulator for a short period of time. When the work machine requires pressurized fluid for the power stroke, the exit port is opened and the weighted ram on top begins to slide gradually, supplying high pressure fluid to the work machine during the power stroke.

This entire movement is repeated over and over again, allowing us to perform difficult tasks with less energy consumption in our daily lives.

Types of Hydraulic Accumulator

1. Weight or Gravity Accumulator:

It is a heavy vertical cylinder. When hydraulic oil is injected, the weight is lifted. The weight exerts a force on the piston, creating pressure on the fluid side of the piston.

The advantage of this type of accumulator over other types is that it provides constant pressure throughout the operating range of the liquid. The main drawback is its very large size and heavy weight. Therefore, it is not suitable for mobile use.

2. Spring Accumulators:

Spring accumulators store energy in the form of a compressed spring. Hydraulic fluid is pumped into the accumulator, causing the piston to move up and compress the spring. A compressed spring then exerts a force on the piston, putting pressure on the hydraulic fluid.

This type of accumulator delivers only a small amount of oil at relatively low pressure. In addition, the pressure applied to the oil is not constant like a self-weight accumulator. When the spring is compressed, the accumulator pressure is maximum, and when the spring reaches its free length, the accumulator pressure is minimum.

3. Gas Accumulators:

Gas accumulators are often used in industry. Here, compressed air exerts a force on the oil. A schematic diagram of a gas-filled accumulator is shown. Gas accumulators can be very large and are often used with water or water-based liquids, using air as the gas charge.

Typical applications are water turbines to absorb pressure surges caused by closing valves and piston pumps to smooth the flow.

Conclusion:

A hydraulic accumulator is an accumulator in which an incompressible hydraulic fluid is held under pressure applied by an external mechanical energy source. External sources can be motors, springs, lifted weights, or compressed gas.

Accumulators allow hydraulic systems to handle extreme demands with less powerful pumps, respond more quickly to transient demands, and smooth out pulsations. It’s a kind of energy store.