Table of Contents

Introduction

The drill press is a versatile and indispensable tool in any woodworking or metal workshop. It acts as a pillar of precision and power when it comes to drilling holes with precision and efficiency. Understanding the different components and parts of a drill press is important for both beginners and experienced craftsmen. In this comprehensive guide, we’ll delve deeper into the intricacies of the drill press, analyzing its key components to provide you with a deeper understanding of how this essential piece of equipment operates.

At its core, a drill press is designed to simplify the process of making holes in a variety of materials, providing unmatched precision and control. Whether you’re working on woodworking projects, metalworking tasks or even some DIY home improvements, a drill press is an indispensable ally that can make your work more efficient and accurate.

To fully appreciate how a drill press works, we need to start with its basic components. The central element of any drill press is the “base”. This strong, often cast iron foundation provides stability and support to the entire machine. This ensures that the drill press rests firmly on your workbench or floor, preventing unwanted vibrations and maintaining accuracy during drilling operations.

At the top of the base is the “pillar” or “pillar”. This vertical support structure acts as the backbone of the drill press, connecting the base to the machine head. The column is usually made of strong material such as steel or cast iron, which ensures rigidity and stability during use of the drill press. The height of the column can be adjusted to accommodate different workpiece sizes, making it an important part of the machine’s versatility.

Moving upward, we reach the “head” of the drill press. This is where the primary action takes place. The head consists of several important components, starting with the “spindle”. The spindle is the rotating shaft that is responsible for holding and rotating the drill bit. It is connected to the motor, which provides the power needed to rotate the spindle and drive the drilling process. Many drill presses offer variable speed options, allowing you to adjust the spindle’s rotation speed to suit the material you’re working with.

Attached to the spindle is the “chuck”. The chuck is a special component designed to securely grip and hold drill bits of various types and sizes. It is often adjustable, allowing quick and easy bit changes. The ability to switch between different drill bit sizes and types is a major advantage of using a drill press, as it allows you to perform a wide range of drilling tasks without the need for multiple tools.

On the side of the head, you’ll find a “depth stop.” This is an important feature to ensure consistent hole depth. By adjusting the depth stop, you can control how deep the drill bit penetrates the material, making it an invaluable tool for precision drilling.

The “table” of the drill press is another essential component. It is a flat, horizontal surface that supports the workpiece during drilling. The table can typically be adjusted in height and angle, providing flexibility to accommodate different workpiece sizes and drilling angles. Some drill presses also have a tilt table, which allows you to drill holes at angles other than 90 degrees, further expanding the capabilities of the machine.

In this guide, we’ll delve deeper into each of these components, exploring their features and functions in more detail, and providing you with the knowledge you need to operate a drill press effectively and confidently.

Parts Of A Drill Press

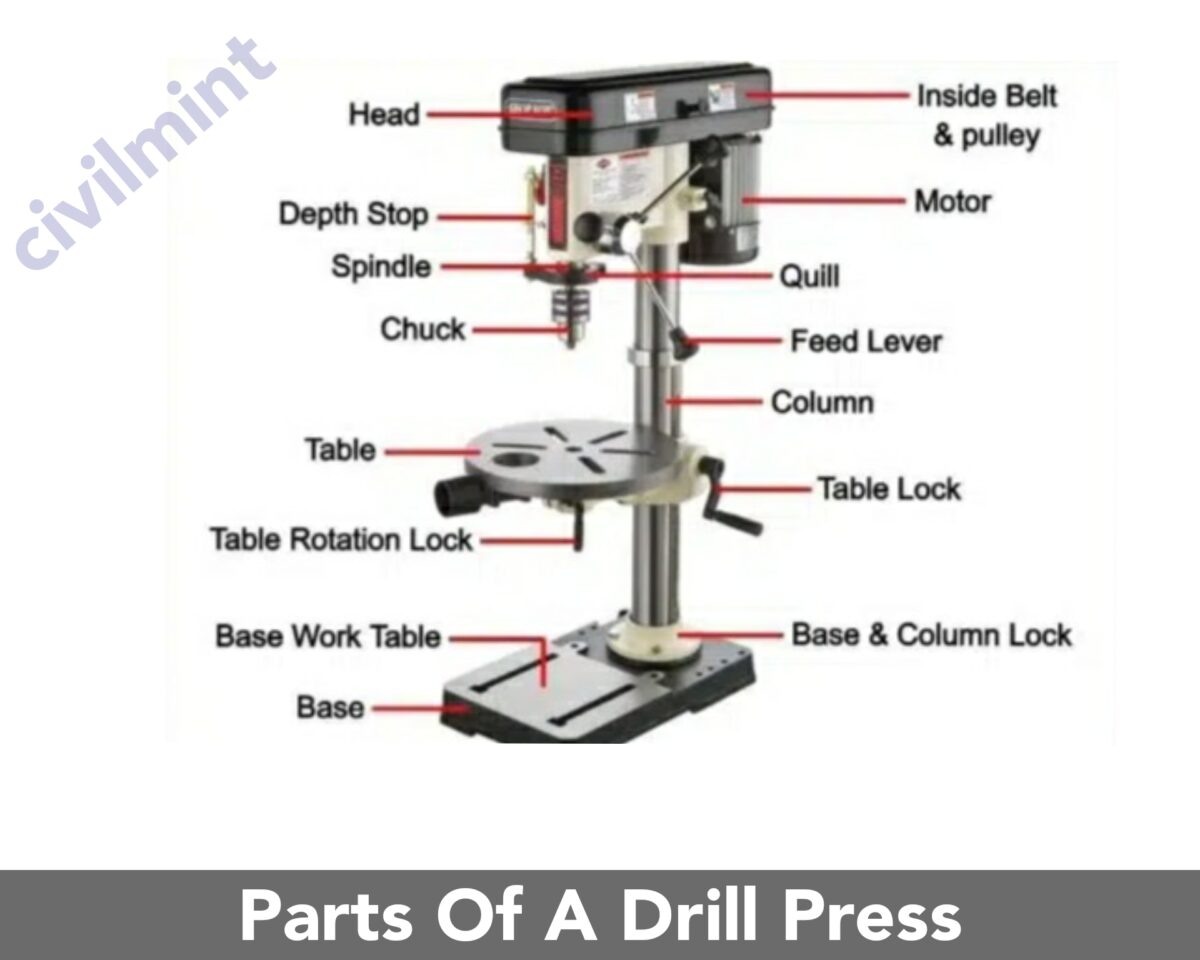

In the picture below, I have shown the parts of a drill press.

1. Column:

The column is the drill press’s backbone, supporting all its components. It must be sturdy and precise for accurate drilling operation.

2. Head:

The head part of the drill press houses the spindle at the top, responsible for moving the spindle upward or downward. Its primary function is to control the drill bit’s depth and securely hold it in place during drilling. Additionally, it houses safety features, the quill lock, and controls for drill speed and feed rate.

3. Spindle:

The spindle is the rotating shaft holding the drill chuck. Proper alignment of the spindle with the material being drilled is essential for precise drilling. The spindle’s speed and power are controlled by the motor.

4. Motor and Belt:

An electric drill press, unlike manual machines, offers efficiency in hole-making tasks. The motor, typically located at the upper back of the machine, powers the drill’s operation. The motor’s power can vary based on the drill bits and drilling requirements, with speed adjustment possible by changing belt positions on pulleys.

5. Power Transmission:

Power transmission, crucial to the drill press, is powered by an electric motor. Transmission occurs through v-belts and opposing pulley stacks, allowing spindle speed control. The interdependence of these components ensures the drill press functions effectively.

6. Base:

The base, typically made of steel or iron, supports the column and stabilizes the drill press. It can be mounted on various surfaces, such as workbenches, pedestals, or floors.

7. Depth Stop:

The adjustable depth stop enables precise drilling to a specific depth. It prevents the drill from going deeper, ensuring accuracy in hole depth.

8. Quill:

The quill, typically within the spindle, raises and lowers it to achieve the desired drilling depth. It is operated by a hand crank or lever, offering adjustable feed rates.

9. Adjustable Stop:

An adjustable stop aids in precise drilling by allowing users to set stopping points and depths for the drill bit.

10. Feed Lever:

The feed lever controls the drill’s upward movement, determining the speed and pressure applied to the workpiece. Some drill presses have automatic feed capabilities.

11. Chuck Arbor:

Chuck arbors connect drill chucks to the machine’s spindle, often using a tapered press connection. They ensure the secure holding of the tool or workpiece.

12. Chuck:

The chuck holds the tooling and can be geared or keyless. It is moved downward using rack-and-pinion gearing controlled by the feed wheel or switch.

13. Table:

The table is connected to the column and adjusted to the required height. It holds the workpiece securely during drilling, with the drill bit moved using the feed lever.

14. Power Switch:

The power switch, usually located on the front of the head, controls the motor’s operation, allowing easy access for turning the drill press on and off.

15. Fence:

A fence enhances the drill press’s precision, particularly in woodworking. It may not be included with all drill presses but can be added for increased functionality and safety.

You might also like: Parts Of A Car Wheel

Conclusion

A drill press consists of several parts, each of which plays a vital role in its functionality. From the sturdy base and adjustable column, to the powerful head with spindle, chuck and depth stop, to the versatile table, understanding these parts is essential to harnessing the full potential of this indispensable tool.