Table of Contents

Introduction of Swivel Joint

Swivel joints are precision-machined components used to connect fixed cargo hoses to prevent bending, reducing flow, rupturing, and releasing harmful chemicals into the air.

Swivel joints are designed in such a way that parts can rotate with respect to other components. Swivel joints have multiple planes of rotation and stress relief to the product line. Be it loading arms, tubes or hoses.

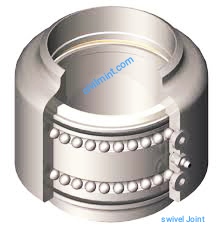

I have shown the typical image of a swivel joint.

Their design allows you to move/rotate one component of the system relative to the other. Industrial swivel joints are designed for a wide range of temperatures and pressures. They must be able to absorb external forces and generated stresses. A well-designed swivel joint can rotate 360 degrees in one, two, or three planes.

What is Swivel Ball Joint?

Swivel ball joint used in combination with nuts for retention purposes, especially when the connecting linkage is threaded. In addition, a DC in-line ball joint is used to control the linkage system.

What is Swivel Socket Joint?

It is a particular type of joint in which screw can be tighten or loosen very easily. The socket head rotates in multiple directions, allowing users to access screws in tight spaces and at various angles.

The socket is linked to a screwdriver that the user turns and applies force to loosen or tighten the screw. The rotatable socket design depends on the intended use of the tool. The socket opening size may also vary to accommodate different size bolts.

How it Works?

A swivel joint usually consists of two main components. sleeves and bodice. They are equipped with ball bearings and are locked by one or more races. These ball bearing races properly align the body and pivot sleeve to allow the swivel to rotate about its axis. Since his two parts of the swivel joint can rotate, the piping system components connected to both ends of the swivel joint are also free and independent to rotate about the axis of the swivel joint. Multiple pivots with different orientations are attached to have multiple axes of rotation. This allows the system to move more freely between the sides of the fluid delivery system. Various types of lubricants can be used to lubricate races.

The actual mechanical work is done by vortex ball bearings. However, the most important part of the swivel joint is the liquid-tight pressure seal that retains the pressurized working fluid. Pressure seals can be made from thermoplastics or elastomers such as PRFE, FKM, Kalrez, fluoroelastomers, Chemraz, and nitrile rubber. The properties of these seal material options allow them to be used with different fluids at different operating temperatures.

Sum Up

Thanks for reading my article on swivel joint. I have described various types of swivel joints and its working. I hope you enjoyed this article.

Keep Reading!

Goodby😊