Tie bar is a metal bar that contractors insert across a joint between two adjacent concrete slabs to prevent differential movement between them and provide load transfer.

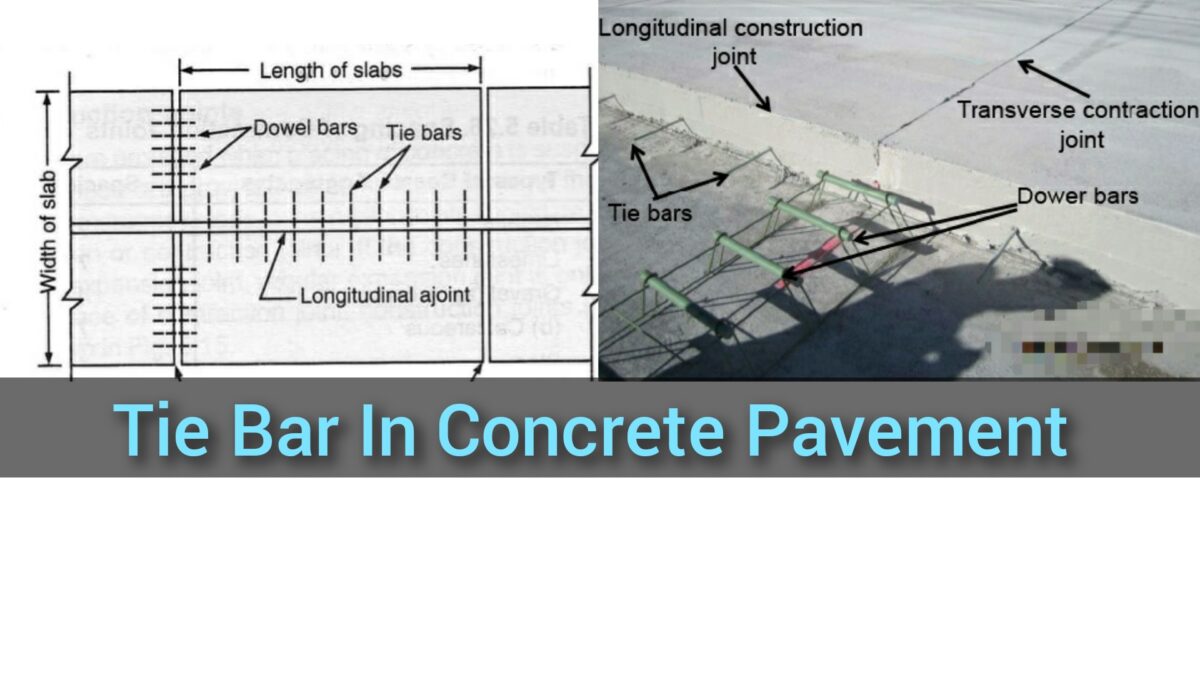

See the below image of tie bar.

To ensure that the individual slabs of concrete pavement are connected to each other and don’t move independently under traffic loads, workers install tie bars perpendicular to the joint. They embed the tie bar in one slab and allow it to protrude into the adjacent slab.

Workers typically coat the protruding end of the tie bar with a bond breaker material to prevent bonding between the two slabs and allow for differential movement. Using tie bars in pavement construction can improve the durability and longevity of concrete pavements by reducing the likelihood of cracking and other types of pavement distress.

Table of Contents

What Is Tie Bar?

Tie bar is a deformed steel bar or epoxy coated steel bar. It is used to hold the faces of the abutting slab. Tie bar is not utilized to transmit load in concrete pavement.

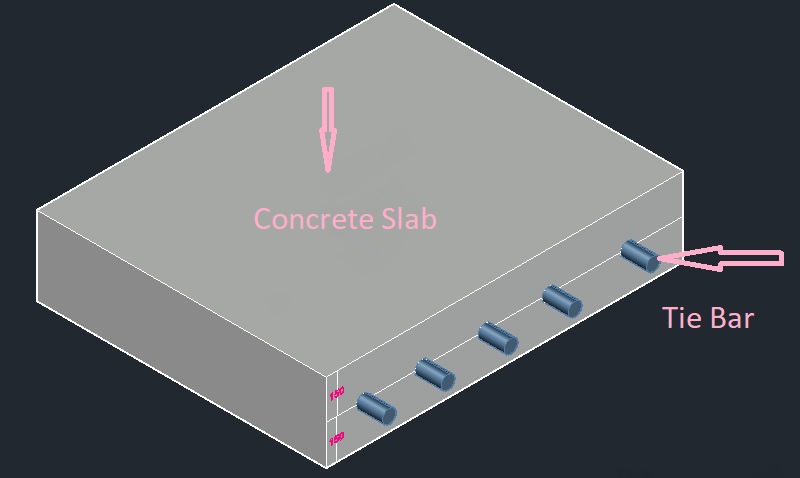

Tie Bars provide in mid-depth of the concrete slab (as shown in the figure). Normally it is provided in the longitudinal direction (refer figure) of the concrete pavement.

Tie bars help to maintain a smooth ride for drivers by minimizing the amount of vertical movement at the joint between adjacent slabs.

Role Of Tie Bar In Concrete Pavement:

- The tie bar prevents lanes from separations.

- Tie bar prevents lanes from deflection of the slab.

- It reduces transverse cracking in the concrete deck.

Tie Bar Placement

To ensure proper alignment and positioning of tie bars, it is crucial to scout the depth and locations beforehand to ensure they are placed appropriately.

Precise insertion of tie bars is necessary to avoid hitting reinforced mats during insertion into fresh concrete. It is also important to insert tie bars a few inches away from the transverse bar to prevent displacement of the carpet.

The size of tie bars used is dependent on the thickness of the concrete surface and the width of the slab. Generally, tie bars are made of steel bars with a diameter of between 12-16mm and a length that varies between 550mm and 640mm.

Tie bars are inserted after one lane is paved, either manually or using a tie bar installer. The tie bar is typically installed mid-depth of the slab and bent back until the adjacent lane is prepared and paved. For longitudinal joints, tie bars are inserted at the edge of the slab using slip-form pavers.

Precautions During Tie Bars Installation

Installing tie bars can pose challenges due to various issues that may arise, such as missing bars, poorly adjusted equipment, poorly consolidated concrete, or misplaced tie bars.

To prevent any movement after placement, it is crucial to exercise utmost care. One should take steps to ensure that the team and equipment do not knock or drag the protruding bars.

Plastic sleeves must be added to the tie bars after installation to prevent the curing compound from adhering to the surface of the bars. Failing to take these precautions can negatively impact the bond development of the concrete, which can compromise the overall integrity of the structure.

Difference Between Tie Bar And Dowel Bar

Tie bars are used to hold adjacent concrete slabs together and prevent horizontal movement. Engineers typically make tie bars from deformed epoxy-coated steel and space them at regular intervals depending on the thickness and width of the slab.

Dowel bars, on the other hand, provide a mechanical connection between slabs and transfer the load uniformly. Engineers typically make dowel bars from smooth, rounded steel bars and space them at regular intervals depending on the thickness of the pavement.

Tie bars prevent horizontal movement between concrete slabs, while dowel bars transfer loads between slabs and provide uniform support.

Advantages

- It enhances the performance of concrete slab joints significantly.

- They save the life cycle cost of the cocnrete slab.

- It makes slab more durable and strong.

Uses And Applications

Tie bars play a vital role in the construction of concrete pavements by providing reinforcement and preventing transverse cracking. One of the primary functions of tie bars is to reduce transverse cracking that can occur due to the natural expansion and contraction of concrete pavement caused by temperature changes. By connecting the concrete slabs, tie bars help to distribute the load evenly, reducing the tensile stress on the pavement.

Tie bars are also frequently used in plain jointed concrete pavements to connect two adjacent lanes. This structural connection between the two lanes helps to maintain the overall stability of the pavement and prevent differential settlement.

Tie bars prevent pavement lanes from deflecting off the slab. Dynamic loads created by passing traffic can cause the slab to deflect or sink, but the presence of tie bars helps to distribute this load evenly, reducing the risk of slab deflection or deformation.

Tie bars are critical components used in the construction of concrete pavements to ensure their durability, stability, and resistance to cracking and deformation.