In this article, we will talk about the types of butterfly valves. There are various types of butterfly valves such as Concentric valve, Eccentric valve, Wafer valve, Lug-style valve, and Rotary valve.

Let’s have a look at different types of butterfly valves.

Table of Contents

1. Concentric Valve

The concentric valve is the most basic and common type of butterfly valve. This valve body connects to the disc. The connecting rod passes through the central axis of the disc. This disc is located in the center of the spool hole and the valve stem is inside the valve body.

The shift valve design is no longer known as a rubber seat valve because it relies on the flexibility of the rubber seat to effectively block fluid flow at shut-off.

When the disc is rotated 90 degrees, it first contacts the valve stem at an angle of approximately 85 degrees. These types of butterfly valves are used for low-pressure applications.

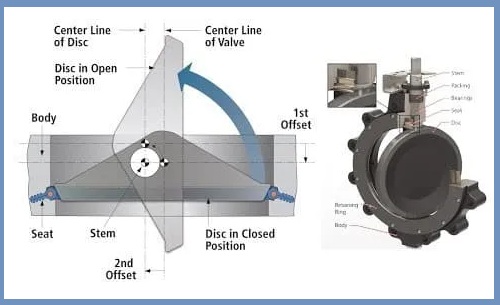

2. Eccentric valve

Eccentric butterfly valves include the best-known types of butterfly valves. The bodies of these valves do not cross the shaft of the disc.

Eccentric valves are used for pulp and paper industries, power, oil refining, mining, and slurry applications.

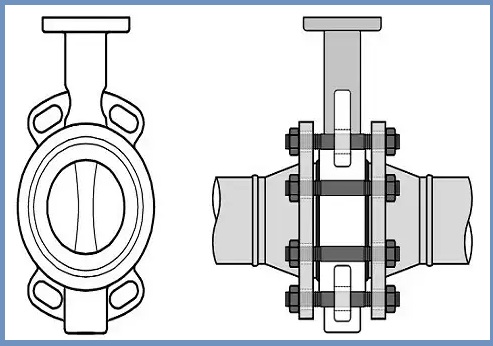

3. Wafer Valve

This type of butterfly valve is cheaper than other types. It clamps between two pipe flanges. Some wafer-style valves have a flange hole on the outside of the housing while others do not have a flange hole.

Pipeline flanges are secured by long bolts that go through the entire valve body. A gasket is installed between the pipe flange and the valve to achieve a leak-free tightness.

An O-ring is used to seal the stem. This design is manufactured to seal bidirectional pressure differentials and prevent backflow in a system designed for shared flow.

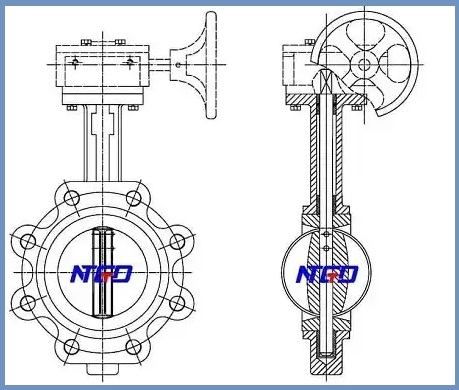

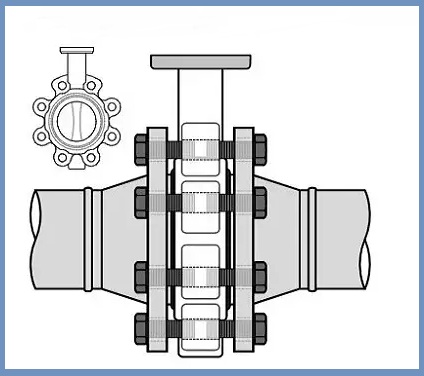

4. Lug-style Valve

This butterfly valve design has threads on both sides of the valve body. These threads help attach the valve to the system without nuts. Only two sets of screws are required for installation.

The rug-style valve connects the two flanges with separate screw sets. In this configuration, one side of the system can be removed without disturbing it.

These butterfly valves are used for dead-end service and generally have low-pressure ratings. It is a versatile solution because it is highly resistant to solvents and chemicals and can withstand extreme temperatures (such as 200° C).

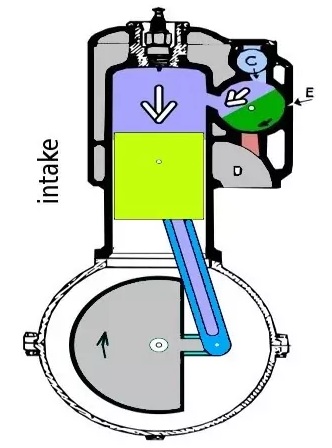

5. Rotary Valve

These valves are most commonly used to regulate the flow of products, usually to reduce the flow rate to the desired level in the system. They are most commonly used in high-performance engines.

Thanks for reading my article on various types of butterfly valves. If you have any thoughts, hit the comment box.

Thanks!

Happy Learning!

Ta! Da!