Normally two types of economizers are used as follows.

- Non-condensing Economizer

- Condensing Economizer

Now we will learn about both types of economizers one by one.

Table of Contents

1. Non-condensing economizer

This type of economizer is used to keep the flue gas temperature above the flue gas condensation temperature to prevent chimney corrosion. This is especially important for fuels containing sulfur.

Sulfuric compounds can form in the flue gas, which increases the overall dew point of the flue gas and can form highly corrosive sulfuric acid when condensed.

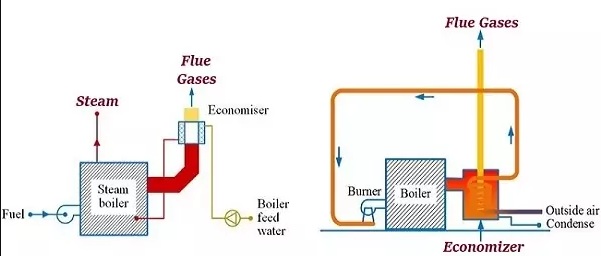

This is the most commonly used economizer. A non-condensing economizer is a heat exchanger coil (usually finned) installed in the chimney at the boiler outlet. They can increase the overall system efficiency by up to 24%.

Benefits of Non-condensing Economizer

- It has the ability to transfer heat from the flue gas to the boiler feed, reducing the need for fuel consumption in the boiler.

- This improves overall efficiency by 24%.

- It is designed to keep the flue gas temperature above the flue gas condensation temperature to prevent corrosion of the chimney.

2. Condensing Economiser

This economizer helps improve waste heat recovery by cooling the flue gas below the dew point of natural gas combustion products (approximately 135°F). The condensing economizer condenses water vapor to recover both the latent heat of the exhaust gas and the sensible heat of the exhaust gas.

As a result, condensing economizers must be highly resistant to acid corrosion and become less effective over time if the heat exchanger components are not kept clean. The Emvertec CEECON economizer avoids this in biomass plants by using an anti-corrosion design and an automatic flush tube cleaning system.

Benefits of Condensing Economiser

- Condensing economizers increase the thermal efficiency of power plants.

- They improve the electrical output of production plants.

- This economizer reduces the fuel consumption of the plant.

- They have the ability to transfer heat to external processes.

- Reduce the moisture content of exhaust gases leaving the chimney.

- The Emvertec CEECON Condensing Economizer goes one step further by polishing the flue gas to reduce the environmental footprint of the plant and further lowering pollutant levels compared to traditional flue gas pollutant removal systems.

- It also protects downstream systems from acid corrosion and provides high-quality heat.