Table of Contents

Introduction:

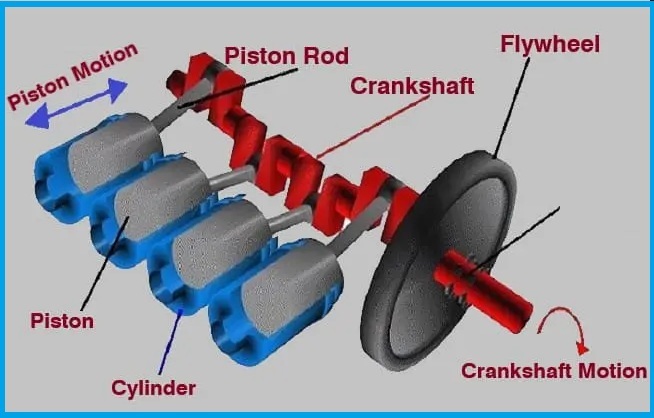

A crankshaft is a mechanical device that converts the reciprocating motion of a piston into rotational motion. The crankshaft is connected to the piston via a connecting rod. The main task of this connecting rod is to receive the reciprocating motion from the piston and transmit it to the crankshaft.

When the crankshaft receives the movement of the connecting rod, it converts that movement into rotational motion and rotates the flywheel to drive the wheels of the car.

Without a crank, a piston engine cannot transmit a reciprocating piston to the drive shaft. Simply put, a piston engine cannot propel a vehicle without a crankshaft.

The crankshaft works on the crank mechanism. It is located inside the engine block. The crank contains the moving components of an internal combustion engine. It has many connecting rods and cranks. The engine connecting rod is attached to the crank through these connecting rod journals and cranks. Different engines complete their work cycles at different crankshaft revolutions. For example, a two-stroke engine completes its duty cycle at one crankshaft revolution and a four-stroke engine completes its duty cycle at two crankshaft revolutions.

How does Crankshaft Work?

The crankshaft works on the crank mechanism. The crank has a connecting rod and a crank connected to the connecting rod. There is a vibration damper that reduces the force on the crank.

The crank has a counterweight that is used to reduce the bending load on the crank. The crankshaft of a four-stroke engine works as follows.

- As the engine piston moves from TDC to BDC (stroke down), it transmits that movement to the crankshaft via the connecting rod.

- The crank also converts the linear motion of the piston into the rotation and transmits it to the camshaft.

- When the camshaft receives rotational motion, the intake valve opens and the air-fuel mixture enters the combustion chamber.

- When the combustion chamber is filled with the fuel-air mixture, the piston moves upward (from BDC to TDC), compressing the mixture. During this process, the camshaft closes both the intake and exhaust valves.

- At the end of the compression process, the first rotation of the crankshaft is also performed.

- At the end of the compression process, the ignition process takes place. The heat generated by the compressed mixture during ignition causes the piston to move down. This strike is known as a power stroke.

- As the piston moves down, the piston transmits the reciprocating motion back to the connecting rod, which in turn sends it to the crankshaft. One end of the crank is connected to the flywheel.

- When the crank detects the movement of the piston, it transmits that movement to the flywheel. The flywheel remembers this movement and makes the wheels of the car move. After the power stroke, the piston moves down to release the exhaust gases. During this process, the camshaft receives piston motion from the crank, opening the exhaust valve while the intake valve remains closed. The piston pushes the exhaust gases out of the combustion chamber.

- After the exhaust stroke, the crank rotates twice and one cycle of the four-stroke engine is also completed. After that, the whole cycle is repeated.

For a better understanding, imagine your foot pedaling a bicycle. In this example, think of the pedals as cranks and the feet as pistons. When the piston is pushed, the reciprocating motion is converted into the rotational motion of the crankshaft.

Crankshaft Design

The materials used to make the crankshaft are:

- cast iron

- carbon steel

- Vanadium micro-alloy steel

- forged steel

The connecting rod can be assembled from various parts or made as a single part (monolithic).

The monolithic type is the most popular crank worldwide. However, some large and small internal combustion engines have prefabricated crankshafts.

These shafts can also be cast from ductile iron, modular steel, or forged steel. Welded joints are cast from steel. This inexpensive method is used on low-cost production engines with reasonable loads. The forging process has excellent strength. Therefore, the forging process is known as the preferred manufacturing process for crankshafts.

Crank casting and forging process

Crankshafts are usually forged from ductile steel castings or can be forged using steel rods. Most manufacturers today use forged crankshafts because of their good damping, compact design, and lightweight. Vanadium alloy steel is mainly used to make forged crankshafts. This is because, after these steels have reached high strength, they can be cooled in the air without further heat treatment, except for the hardening of the supporting surfaces. In addition, the low alloy content makes the material cheaper compared to high-alloy steels. Carbon steel can be used, but carbon steel requires additional heat treatment to achieve the required material quality. Cast iron crankshafts today are mainly used in engines with low load and economic performance (eg Ford Focus diesel engines).

Currently, only some engines use cast iron crankshafts on cheaper, lower power versions, while more expensive and more powerful engine versions use forged steel crankshafts.

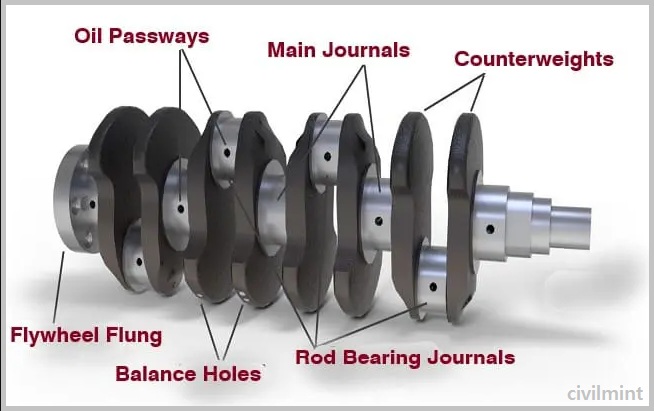

Crankshaft Components

- Main Journal

- Crankshaft Pulley

- Oil Passways

- Balance Hole

- Counterweight

- Crankshaft Lubrication

Uses of Crankshaft

- The crankshaft controls the movement of all valves for the intake, compression, ignition, expansion, and exhaust processes of an internal combustion engine at precise cycle times.

- This is a great feature. It captures the rotational motion of the connecting rod and transmits it to the flywheel.

- A crankshaft is used to convert the reciprocating motion of a piston into rotational motion so that it can move towards the wheels of a car.