Table of Contents

Waffle Slab

A waffle slab is made of reinforced concrete with holes underneath, giving the appearance of waffles. Waffle slabs are preferred for large spans greater than 12 meters. Waffle slabs are stronger than flat slabs, flat slabs with drop panels, two-way slabs, one-way slabs, and one-way joist slabs. It is used to avoid many columns interfering with space.

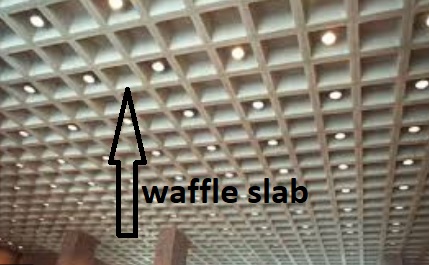

The below image is an example of a typical waffle slab.

It is flat on top while it appeared like a grid-like surface on the bottom. The grid is created by the removal of molds after the concrete sets.

Purpose Of Waffle Slab:

Waffle Slab gives stiffer and lighter slabs than an equivalent flat slab. The speed of development for such a section is quicker contrasted with the customary chunk. Generally lightweight subsequently practical. It utilizes 30% less concrete and 20% less steel than a pontoon chunk. They give low floor avoidances. It has great completions and vigor. Genuinely thin floor profundity and fireproof. Great vibration control.

Uses of waffle slab

- It is used where vibration can cause problems and the place where massive span slabs are to be constructed that is in areas where the number of columns is small.

- For example in airports, hospitals, commercial buildings, and industrial buildings, and place low slab deflection and excessive stability are needed.

Advantages of a waffle slab:

- It provides a large span of the slab with fewer numbers of columns.

- Vibration control capacity is higher.

- Sometimes it is used for the purposes of aesthetics.

- Load-bearing capacity is more than a flat slab.

Disadvantages of a waffle slab::

- The quantity of formwork material is very high.

- The maintenance cost is high.

- Not suitable if wind velocity is high.