Water Jet Machining is a process in which a high-speed velocity jet of water is utilized to remove the material from the surface of the workpiece. Water Jet Machining is also known as water jet cutting.

water jet cutting is used to cut soft materials such as plastic, wood, rubber, etc. To cut harder materials like iron, an abrasive material is mixed with water. This process of using abrasive material with water is known as Abrasive Water Jet Machining (AWJM).

Table of Contents

How does it Works?

It depends on the principle of water disintegration. At the point when a high-speed jet of water strikes the surface, the evacuation of material happens. An unadulterated water stream is used to machine softer materials. Yet, to cut harder materials some abrasive particles are blended with the water for machining and it is called AWJM (Abrasive Water Jet Machining).

The most usually involved grating particles in AWJM are garnet and aluminum oxide. Sand (Si02) and glass beads are likewise utilized as abrasives. The capacity of the rough particles is to improve the cutting capacity of the water jet.

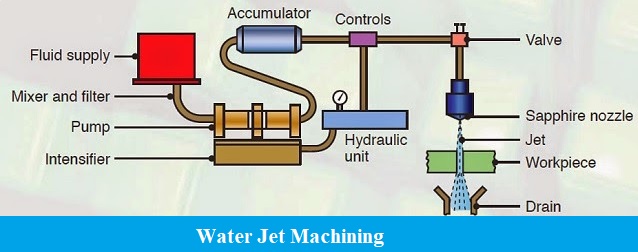

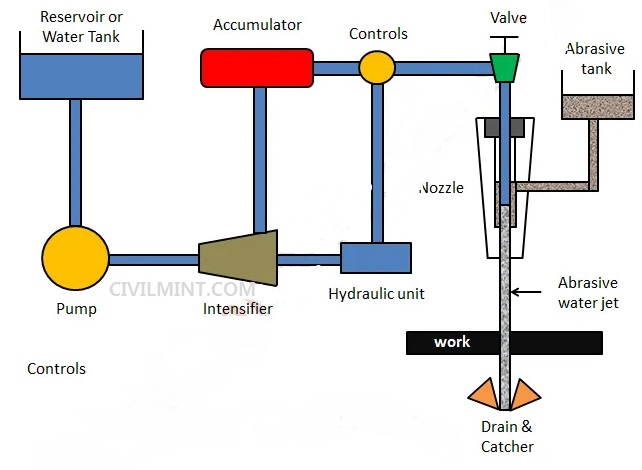

Parts of Water Jet Machining

1. Hydraulic Pump

It is utilized to circle the water from the capacity tank during the machining system. The siphon conveys water to the intensifier at a low pressure of around 5 bars. A booster is likewise utilized which builds the pressure strain of water to 11 bar prior to conveying it to the intensifier.

2. Hydraulic Intensifier

It is utilized to expand the pressure of water to exceptionally high pressure. It gets the water from the siphon at 4 bar and builds its pressure up to 3000 to 4000 bar.

3. Accumulator

It stores the high-compressed water briefly. It supplies that liquid when a lot of pressure energy is required. It takes out pressure vacillation conditions in the machining system.

4. Blending chamber or cylinder

It is a vacuum chamber where the blending of rough particles into water happens.

5. Control Valve

It controls the pressure and bearing of the water jet.

6. Stream Regulator or Valve

The progression of the water is controlled with the assistance of the stream controller.

7. Nozzle

It is a gadget that is utilized to change over the pressure energy of water into kinetic energy in water jet machining. Here spout changes over the pressure of the water jet into the high-speed light emission water stream. The tip of the spout is made of ruby or jewel to keep it from disintegration.

8. Drain and Catcher System

After the machining, the flotsam and jetsam and machined particles from the water are isolated with the assistance of the channel and catcher framework. It eliminates the metal molecule and other undesirable particles from the water and sends them back to the repository for additional utilization.

Working Procedure

The water from the supply is siphoned to the intensifier with the assistance of a siphon. The intensifier builds the pressure of the water from 5 bars to 3000 to 4000 bar. This high-pressure water from the intensifier is moved to the spout as well as in the aggregator. The aggregator stores the high-pressure water and supplies it at any moment when it is required. It is utilized to take out the change of the great tension prerequisite of machining hard material.

The high-pressure water is then passed to the spout where the high-pressure energy of the water is changed over into motor energy. An extremely high-speed stream of water (1000 m/s) emerges through the spout as a tight shaft.

Rough, for example, garnet or aluminum oxide is blended in with water inside the spout. A blending chamber is there in the spout where the abrasives get blended in with the high-pressure water.

This high-speed stream of water when strikes the outer layer of the w/p eliminates the material from it.

The water jet subsequently to machining it gets gathered by the channel and catcher framework. Here the flotsam and jetsam, metal particles from the water are eliminated and it is provided to the repository tank.

Applications of Water Jet Machining:

Various applications of water jet machining are as follows:

- Milling

- Cutting

- Turning

- 3D Shaping

- Piercing

- Drilling

- Polishing

Advantages of Water Jet Machining:

- It is eco-friendly and does not produce toxic elements.

- It has a very high precision of ± 0.005 inches.

- It can cut both hard and soft materials.

- There is no heat generation.

- The maintenance cost is very low.

- It has a low operating cost.

- The work area remains very clean.

- It can cut complex shapes.

Some Drawbacks:

- The initial cost to set up water jet machining is very high.

- Very thick material can nor cut using this process.