Stiffener plates are used to increase stiffness and resistance against buckling. In this blog article we will discuss about stiffener plate in detail.

Table of Contents

What Is Stiffener Plate?

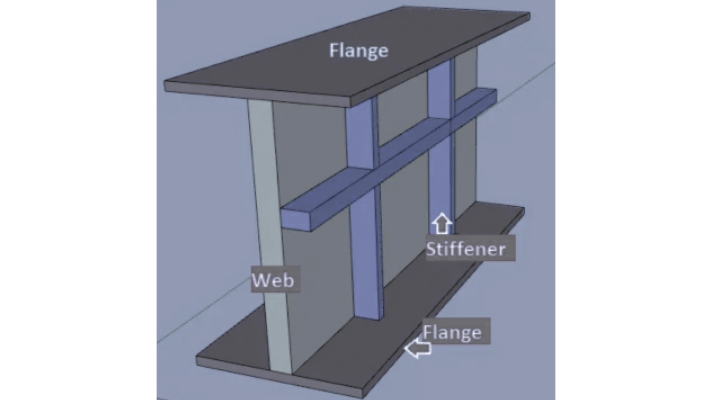

Stiffener plate is a structural component used to reinforce and strengthen plate girders, making them more rigid. They are typically plates that are welded to the web of the girder. These plates can be applied on one side of the web or both sides, effectively increasing the moment of inertia of the plate girder. This enhanced rigidity prevents buckling.

In the diagram above, both longitudinal and transverse stiffeners are illustrated. Longitudinal stiffeners can improve the shear and bending strengths of the plate girder, but they are not as essential as transverse stiffeners. Nonetheless, they are used in highway bridges with deep beams.

Transverse stiffeners are employed to enhance the shear capacity of the web, ensuring its structural integrity under various loads.

Additionally, plates may be used under heavy concentrated loads to increase bearing resistance; this is known as bearing stiffeners.

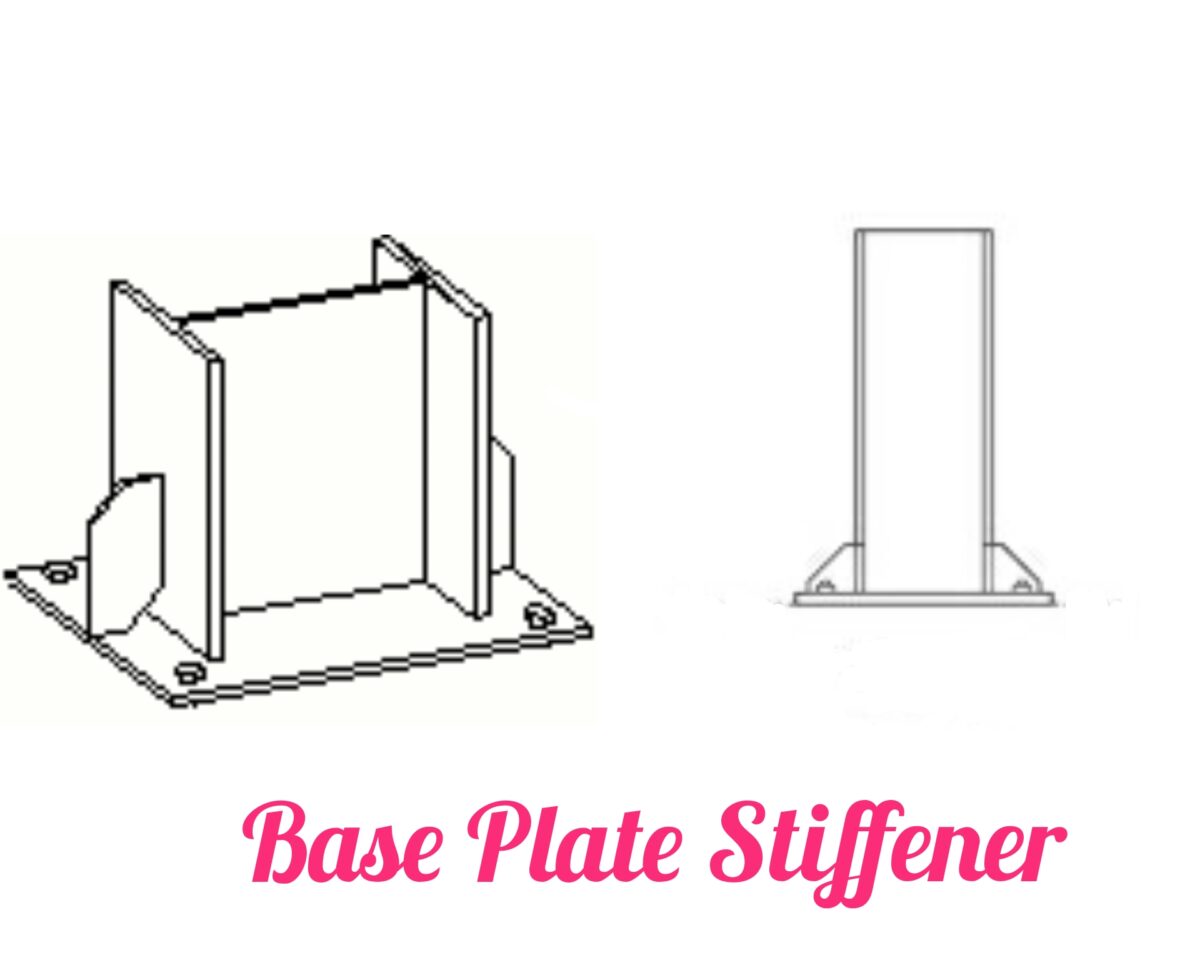

Base Plate Stiffener

In structural steel construction, a base plate stiffener steel connection is a common method used to enhance the strength and stability of tall buildings and other structures under heavy loads.

The connection involves a base plate, a large metal plate securely connected to the column’s bottom, and smaller metal stiffeners welded to the base plate.

These stiffeners play a crucial role in reinforcing the base plate, preventing any potential buckling when subjected to significant loads. This connection type is widely utilized in various construction projects due to its effectiveness and reliability.

Various Types Of Stiffeners Plates In Steel Structure

Different types of stiffener plates are used as per the design requirement of the steel structure.

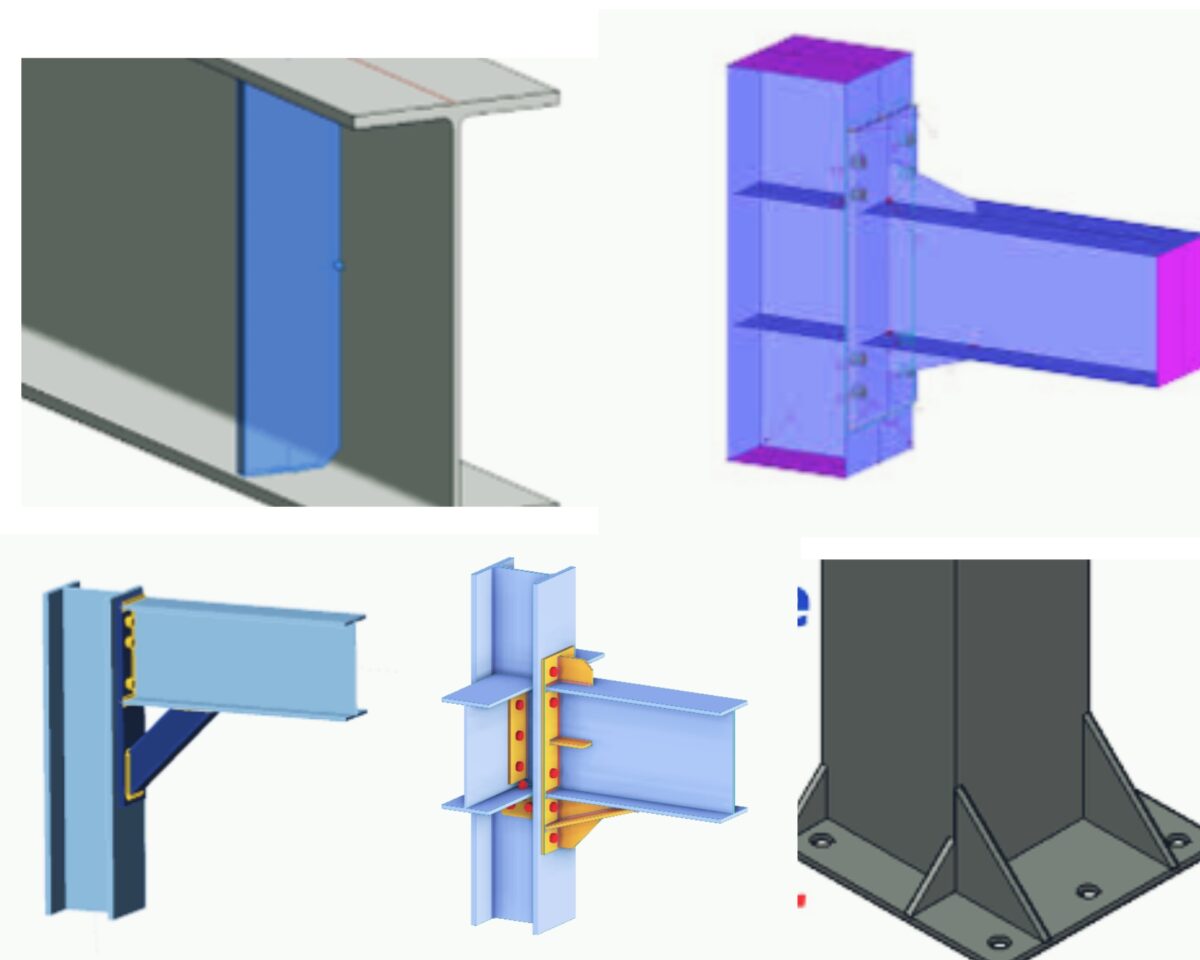

1. Flange Stiffeners:

These plates are attached to the flanges of steel beams or girders to prevent lateral torsional buckling and improve their flexural strength.

2. Web Stiffeners:

Placed along the web of beams or columns, web stiffeners are instrumental in resisting shear forces and enhancing the overall stability of the member.

3. Column Stiffeners:

Employed in column design, these plates help control local buckling and enhance the column’s load-carrying capacity.

Points To Remember While Designing Stiffener Plates

As we know all structural design software give design based on input. Structural engineers need to carefully consider a variety of factors, including the size and direction of loads, material properties, and steel member dimensions. Structural engineers must also ensure that the dimensions, thickness and spacing of stiffeners are optimized to achieve the required structural performance while avoiding over-design and unnecessary material use.

The Bottom Line

Correct installation of stiffener plates plays an important role in ensuring the structural integrity of steel components. Engineers and designers must carefully evaluate whether welding techniques, bolted connections, or a combination of the two are best suited for their attachment. Regular inspection during construction and throughout the lifetime of the structure is extremely important to identify potential issues and guarantee the continued effectiveness of the stiffener plates.

Stiffener plates are indispensable elements in steel structures, providing vital reinforcement to withstand significant loads and maintain stability. Their proper placement and thoughtful design are paramount to optimize structural performance, resulting in safe, reliable and cost-effective steel construction.

Read Also: Gusset Plate In Steel Structures

By prioritizing careful planning and attention to detail, we can create strong steel structures that stand the test of time and contribute to the safety and longevity of our built environment.