Folded plates are structures that are obtained by assembling flat plates rigidly along their longitudinal edges such that the final structural system carries loads without the need for additional supports like beams along their mutual edges. Folded plate structures are 3-D structures or special structures that are derived from folded structural element which maintain mutual relationship in space.

Compared for other shell structures, folded plate structures are easily manufactured with less use of formwork material. But, as it has more bending in alignment, more material is consumed compared to other shell structures.

Table of Contents

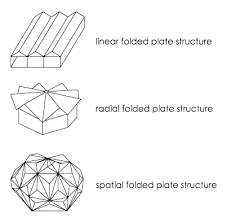

Types of Folded Plate Structures

Modern folded plates are cast in situ or precast reinforced concrete, or steel plate. Folded plate structure is classified primarily based on the shape of the final structure. This affects the load transfer mechanism as well as the direction of relying folded structure. Based on this, folded plate structure can be classified as:

- Linear Folded Plate Structure

- Radial Folded Plate Structure

- Spatial Folded Plate Structure

Analysis of Folded Plate Structures

The basic assumptions while analyzing folded plate structures are:

- The material used (concrete in our case) is homogeneous, monolithic and “elastic“.

- Longitudinal vertices are continuous and held in such a way that there is no relative rotation or sliding along the common boundary between two adjoining plates.

- Plates have very small resistance against twisting and torsion and therefore those stresses are usually considered small and thus ignored.

- End diaphragms or bents, if any, are provided to transmit end reactions from the plates to the columns, however, they are generally considered unable to provide restraint against rotation at the end of the plates.

- For longitudinal spans of 50 feet and over, bridging is recommended at midpoint. For spans from 70 to 100 feet, bridging should be provided at the third points of the span. Bridging should be of not less than 4 inches in thickness and have adequate openings at the bottom of the valley to facilitate drainage.

- The principle of superposition holds true and valid. This means that the structure is susceptible to being analyzed separately for its redundant forces and different loading conditions. Then, at the end, the final answer is obtained by algebraically adding all.

Pros and Cons of Folded Plates

Pros :

Folded plate roof structures provide an assortment of advantages for property owners. They include:

- Since they have high durability and weight-bearing capacity, these structures are capable of carrying loads without needing additional support beams. This technology is ideal for large buildings including factories, warehouses, supermarkets, museums, and stadiums.

- Materials that can be used include steel, glass, and concrete, which help create secure buildings that are filled with usable space.

- Due to the design of folded plate roof details, both labor and materials are lower in cost than other roofing styles.

- They’re both easy for architects to design and offer plenty of design options.

Cons :

Folded plates also have a few disadvantages that you should be aware of. They include:

- The construction of folded plate roofs can be difficult.

- It requires great accuracy, exceptional labor, and close supervision.

- Although the basic construction is logical, you’ll need numerical computation for accurate results. This can prove to be tedious.

Installation cost

The good news about this roofing style is that it’s often a cost-effective choice for a variety of commercial and industrial buildings. Why? It’s both faster and easier to assemble than other types of roofs, which helps reduce labor costs.

If you’re in need of an estimate for roofing installation or replacement, get in touch with your local roofing contractor. They’ll be happy to walk you through your cost options depending on the style and material you choose.

Materials Used for Folded Plates

Folded plate roofs can be constructed from a variety of high-quality materials. Ones that are the most often used include steel plate, reinforced concrete, or tempered glass. In the sections below, we’ll discuss each material in detail to help you make a more informed decision.

When you’re installing or replacing a roof, it’s a good idea to consult with an expert to determine which style of roof and material will work best for you. We recommend getting in touch with your local roofing contractor to get started with your project. They’ll be able to walk you through the process.

Steel Plate

Steel is one of the most commonly used materials for this roofing type due to its strength and durability. Steel folded plate roofs not only provide an interesting appearance but also offer the option of having large column-free areas. As for design, a standard module that’s open to prefabrication was created. Design charts have been prepared by experts, and they can be used for the preliminary design of steel frame folded plate roofs without having to use rigorous computer methods. Property owners interested in using steel can contact their local roofing company to get started on their project.

Reinforced Concrete

Reinforced concrete is another one of the most popular materials used for folded plate roofs. Like steel, it’s known for both its strength and durability. The basic idea of creating a concrete folded plate roof was to achieve more constructive height and better rigidity while reducing the overall weight of the structure. It’s noteworthy to add that the strength of this type of construction is achieved through the proper design rather than the materials that form it. If you’re interested in concrete folded plate roofs for your property, get in touch with a local roofing contractor as soon as possible.

Tempered Glass

Last but not least, tempered glass is the third material that’s most often used for folded plate roofs among property owners. You can use either glass alone or combined with other materials to make various roof, wall, and floor constructions. Whether you select glass or another type of material for your folded plate roof, you can rest assured that the structure will have an intrinsic rigidity and high load-bearing capacity. If you’re a property owner who would like to install tempered glass on your home or business, please do not hesitate to call your local roofing contractors.

Relatively speaking, folded plate structures are simple to install. The method we discussed was developed in China and is now used in other parts of the world.