In this post, we will discuss about air compressor and all the important things related to the air compressor. Air compressor converts electrical energy into potential energy.

Table of Contents

What is Air Compressor?

An air compressor is a pneumatic device that converts electrical power into potential energy stored in compressed air. Using one of several methods, the air compressor pushes more air into the storage tank, increasing the pressure. The air compressor stops when the tank pressure reaches the technical limit. Compressed air is held in a tank until it is needed.

The kinetic energy provided by compressed air can be used in many different ways such as pneumatic tools because air is released and the tank is depressurized. When the tank pressure reaches the lower limit, the air compressor is turned on again to re-pressurize the tank. It should be distinguished from pumps because air compressors work with any gas/air, whereas pumps work with liquids.

How to Cool Air Compressor?

Due to adiabatic heating, air compressors need a way to handle waste heat. Generally this is some form of air or water cooling, but some can be oil cooled.

Atmospheric changes are also taken into account when cooling the compressor. The type of cooling is determined by considering factors such as inlet temperature, ambient temperature, compressor capacity and coverage. There is no single type of compressor that works for all applications.

Types of Air Compressor

There are 4 types of air compressor as given below.

- Centrifugal Air Compressor

- Axial Air Compressor

- Rotary Air Compressor

- Reciprocating Air Compressor

We will learn about these 4 types of air compressor.

1. Centrifugal Air Compressor

It is a continuous flow compressor. A centrifugal compressor is a mixed flow compressor in which air enters the compressor axially and is discharged radially. Rotating the impeller gives the air a dynamic effect. The rotating impeller gives the air a large inertial force. The airflow passing through the compressor goes through several stages. At each stage, the air passes through impellers and diffusers where it slows down and increases in pressure. At the end of every stage, highly compressed air is discharged. Centrifugal compressors used in small scale where less air pressure is required due to low flow rate and low efficiency. The main advantage of this compressor is its cost, due to its ease of manufacture.

2. Axial Air Compressor

Axial flow is another type of dynamic flow air compressor. Air is compressed by the dynamic action of rotating elements. As the name suggests, the flow in the compressor is parallel to the axis of rotation. The rotor of an axial air compressor has multiple rows of airflow that help compress the air at high pressure. Compress air continuously. The rotor of a compressor consists of multiple fixed and rotating blades. Rotating blades torque the air while stationary blades slow down the flowing air. The air entering the compressor is at high velocity and low pressure, but is eventually fully compressed. Due to the multi-blade arrangement, the compressor structure is large and complicated, and the cost is high. The main advantages of axial compressors are their high efficiency and high mass flow.

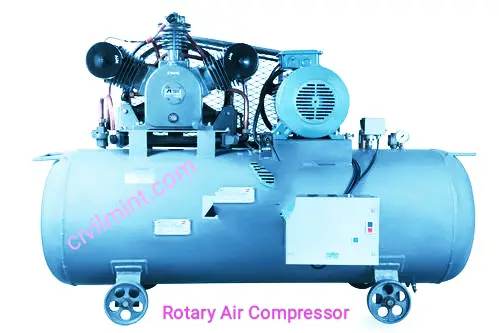

3. Rotary Air Compressor

In a rotary compressor, a rotating linkage rotates inside the cylinder. Rotary compressors are further categorized by the type of rotary linkage, but in terms of a simple rotary compressor, there is a shaft fixed in the center of the cylinder, and an external force causes a pulley to rotate around the shaft. Part of the rotor is always in contact with the inside of the cylinder. It draws in air from one side and expels it to the other side by rotating the rollers. For small mass flow rates where continuous work is required.

4. Reciprocating Air Compressor

This is another type of positive displacement compressor. The piston is responsible for reciprocating motion within the cylinder. The structure and operation are very simple. There is a cylinder with two openings. One for supply air and one for exhaust. When air enters through the first port, the second port remains closed. After also closing the intake port, the piston rises and compresses the air, reducing its volume after the pressure port opens and the compressed air comes out. This cycle repeats incessantly. It will supply air at very high pressure.