A positive displacement compressor works by introducing a certain amount of air into the compression cylinder. A compression cylinder compresses air by mechanically reducing the volume of air. It is known as a positive displacement compressor because it compresses the hydraulic fluid by displacing the volume of the compression cylinder.

This compressor has reciprocating parts such as plungers, pistons, diaphragms, vanes, etc. inside the compression cylinder.

Positive displacement compressors cannot provide a continuous flow of liquid. Positive displacement compressors are less efficient than centrifugal compressors.

These compressors are characterized by excellent quality, high reliability, affordability, and excellent versatility. Therefore, positive displacement compressors are most commonly used in LPG plants, refrigerators, chemical plants, fertilizer industries, workshop cylinders, and many other applications. Bicycle pumps and bicycle pumps are the most common examples of positive displacement compressors.

Table of Contents

How Does Positive Displacement Compressor Work?

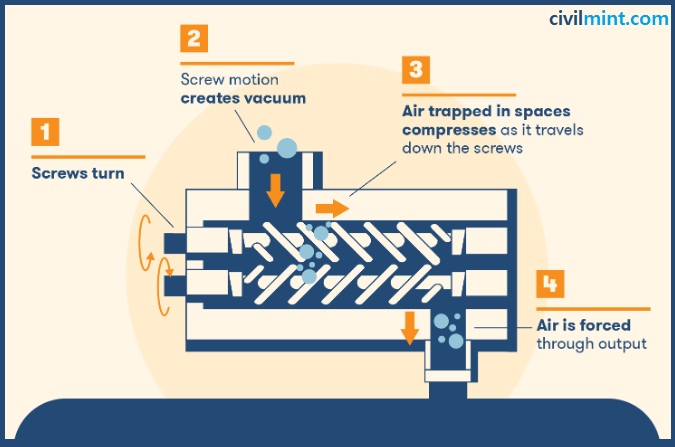

Displacement compressors operate according to the displacement principle. The operation of the PD compressor is very easy. This works as follows:

- First, the air is sucked in to the compression chamber by a suction valve. Compressors use moving parts such as pistons, and diaphragms to compress air. This reciprocating component makes TOO and FRO movements within the compressor chamber.

- Reciprocating components reduce the volume of the compression chamber and compress the air. When the air or gas pressure reaches the requirement, the release valve opens and the compressed air is released. The compressed air or gas is then stored in a storage tank or sent to the desired location.

- These compressors have one or more compression chambers and multiple inlet ports. There are different types of

- positive displacement compressors, but all of these types have the same operating principle.

- A very familiar example of a positive displacement air compressor is a bicycle pump, where air enters a cylinder and is compressed by a moving piston. Then move on to the bicycle tires.

Types of Positive Displacement Compressor

- Reciprocating compressor

- Rotary vane compressor

- Scroll compressor

- Screw compressor

Pros

- This type of compressor has a lower manufacturing cost.

- The components are easy to manufacture.

- These have a wide range of pricing options.

- It is highly efficient.

- This type of compressor has a high-pressure ratio.

Cons

- Requires advanced maintenance.

- Noisy compared to dynamic compressors.

- Not suitable for high flow rates.

- In reciprocating engines, imbalances remain, resulting in more component failures. It is high.

- These compressors are not suitable for dirty gas.

- The capacity range of positive displacement air compressors is limited. It will be less reliable.

Applications/Uses

- This type of compressor is used in refrigerators.

- Used in chemical plants.

- These compressors are used in hydraulic cylinders.

- These are used in cylinders in auto repair shops.