Table of Contents

What Is Ballastless Track?

A ballastless track, also known as a slab track, is a type of railway track infrastructure where the traditional combination of elastic ties/sleepers and ballast is replaced by a rigid construction of concrete or asphalt.

Instead of using a layer of crushed stones or gravel as a foundation, ballastless track systems employ a solid, rigid structure made of concrete or precast concrete to directly support the rails.

This design eliminates the need for ballast and provides a more stable and durable track system. Ballastless track offers advantages such as reduced maintenance requirements, improved track stability, and enhanced ride quality for trains.

Properties Of Ballastless Track

- Ballastless tracks utilize rigidly fastened rails on special concrete ties embedded in concrete.

- These tracks ensure consistent track geometry, as adjustments are not possible once the superstructure is concreted.

- Consequently, ballastless tracks must be concreted with a tolerance of 0.5 millimeters.

- The elasticity found in traditional railway superstructures, provided by the ballast, is replaced in ballastless tracks by flexibility between the rails and concrete ties/sleepers, or between the sleepers and the concrete or asphalt slab. The conglomerate of the tie also contributes inherent elasticity, while the concrete or asphalt slab is typically inelastic.

Design Components Of Ballastless Track

- Rail

- Rail fastening system

- Sleepers and ties

- Concrete or asphalt base layer

- Gydraulically bound base layer

- Frost protection layer

- Subsoil

Ballasted Track Vs Ballastless Track: Differences

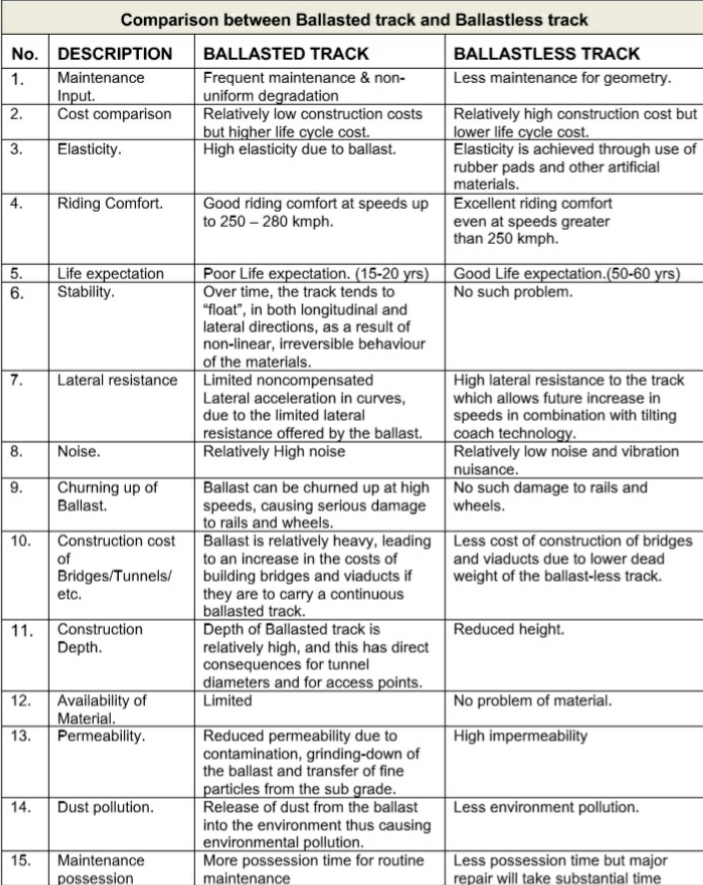

In the below image, I have shown all the key differences between ballasted track and ballastless track.

Benefits Of Ballastless Track

1. Stability:

Ballastless track systems offer improved stability by eliminating the use of traditional ballast, which can shift over time and cause track misalignment. This enhances train operation and reduces maintenance needs.

2. Higher Speeds:

Ballastless track systems are designed to accommodate high-speed trains, enabling faster and more efficient transportation. Without ballast, the risk of ballast flying up during high-speed operations is eliminated, reducing potential damage to trains and infrastructure.

3. Reduced Maintenance:

Ballastless track requires less maintenance compared to traditional ballasted tracks. Without the need for regular ballast adjustments, maintenance costs and labor are significantly reduced. Moreover, issues like ballast fouling or water accumulation are avoided.

4. Durability:

Ballastless track systems are typically constructed with durable materials like concrete or steel, ensuring resistance to wear and tear. They can handle heavy loads, repetitive stresses, and environmental factors, resulting in longer track lifespan and improved reliability.

5. Noise And Vibration Reduction:

The rigid structure of ballastless track systems helps minimize noise and vibration generated by passing trains. This is particularly advantageous in urban areas, where noise pollution is a concern. Reduced vibrations also contribute to the longevity of the track and surrounding structures by minimizing fatigue and potential damage.

Limitations

The main disadvantage of a ballastless track is its higher initial construction cost compared to traditional superstructures. Ballastless tracks can be around 28 percent more expensive to build. However, over the long term, ballastless tracks tend to have lower life-cycle costs due to reduced maintenance needs.

Other drawbacks of ballastless tracks include the inability to adjust or correct track geometry once the concrete is set, the requirement for a stable infrastructure with limited options for modifications to the superstructure, increased noise emissions, and longer repair times if the concrete slab is damaged. The inflexibility of the track is also considered a disadvantage.

Faqs

Ballastless track is a type of railway track design that eliminates the need for traditional ballast materials. Instead of using gravel or stones as a foundation, ballastless track utilizes a solid concrete or composite slab as the trackbed. This design provides enhanced stability, reduced maintenance, and improved longevity compared to traditional track systems.

Ballastless track offers several advantages over traditional track systems. It provides better track stability, reducing track deformations and maintenance requirements. It also offers improved load distribution, resulting in reduced wear and tear on the track components. Additionally, ballastless track has a longer lifespan and offers smoother and quieter train operations.

The design of ballastless track involves several key considerations. The trackbed is typically constructed using precast or cast-in-place concrete slabs or composite materials. The slabs are reinforced with steel or fiber-reinforced polymers to provide structural integrity. The design includes features such as rail fastening systems, rail profiles, and expansion joints to accommodate thermal expansion and contraction. Geometric parameters, such as track alignment and gradients, are also taken into account during the design process.

When selecting ballastless track, several factors should be considered. These include the intended usage of the track (e.g., high-speed rail, metro systems, heavy freight), the expected traffic load, the site conditions (such as soil characteristics and water table levels), and the local climate. Additionally, factors such as construction costs, maintenance requirements, and long-term durability should be evaluated to determine the feasibility and cost-effectiveness of ballastless track.

While ballastless track offers numerous benefits, there are some limitations and challenges to consider. The initial construction costs of ballastless track tend to be higher compared to traditional track systems, which may require a larger upfront investment. Additionally, the design and construction of ballastless track require specialized expertise and equipment. Maintenance and repair of ballastless track can also be more complex and may require specialized techniques. However, these challenges are often outweighed by the long-term advantages of ballastless track in terms of performance, durability, and reduced maintenance costs.