Table of Contents

What Are Built Up Steel Sections?

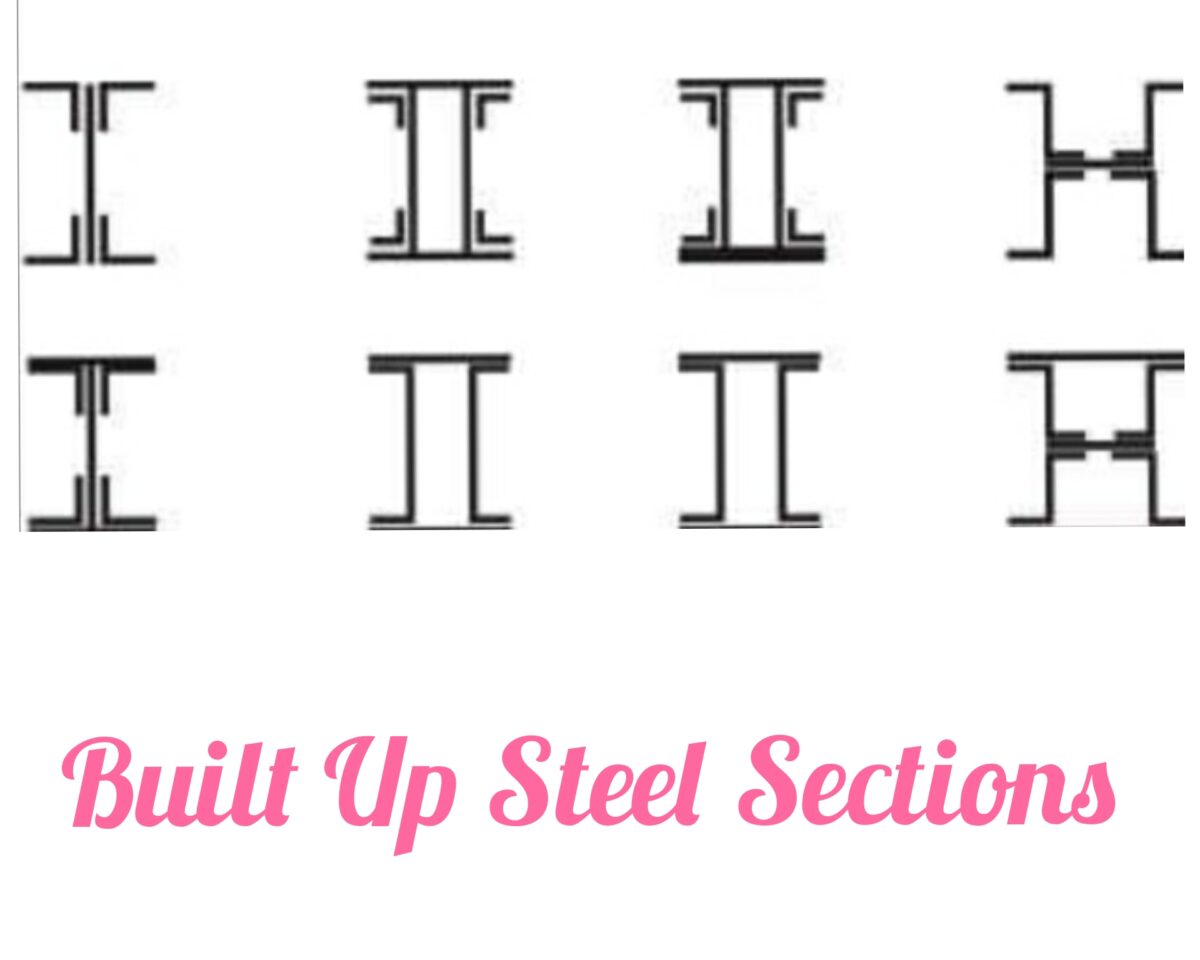

Built up steel sections are made by joining two or more steel sections together. Steel sections manufactured to specific project requirements are used to achieve the desired strength.

Various steel sections such as I section, H section, channel section and other steel sections are used to make built up steel sections. Fabricated sections can be made using welded or bolted connections.

Generally, steel sections manufactured to withstand heavy loads are used. The main advantage of built up steel section is that it can be customized in any shape and size which is not possible with hot rolled steel section. Easy customization made fabricated steel sections more suitable for complex steel structures.

Built up steel sections are cheaper than hot rolled steel sections. Scrap steel can be used to make built up steel sections. There are some disadvantages to making built up steel sections. The analysis and design of built up steel sections is difficult. Formed steel is also difficult to manufacture. The design is more prone to failure than a hot rolled steel section.

Properties Of Built Up Steel Sections

- Manufactured steel sections can handle heavy loads.

- The manufactured sections are light weight.

- The manufactured sections are flexible and suitable for complex steel structures.

- The fabricated sections are made corrosion resistant.

- These types of sections are cheaper than rolled steel sections.

- The manufactured sections can be designed in the desired shape. They can easily bear twisting force without any deformation.

How To Make Built Up Sections

The first step in making a fabricated section is to join the steel sections together. Now these steel sections are cut to the required size. Later, these segments were aligned and assembled. Quality checks are carried out to ensure that the assembled steel part is free from defects and meets the required standards.

Benefits Of Built Up Steel Sections

Built up steel sections have various advantages over conventional rolled steel section.

1. High Strength

These sections are extremely sturdy and can withstand heavy loads and external forces, making them ideal for building large structures.

2. Customized Sections

By combining different forms of steel, engineers can create custom sections tailored to the specific requirements of a building or bridge, improving overall design flexibility.

3. Profitability

Although steel is a premium material, the use of composite parts makes efficient use of resources, reduces material waste, and ultimately reduces costs.

4. Durability

Steel is known for its durability and resistance to environmental factors such as rust and corrosion, ensuring the longevity of the paired steel bars.

5. Ease Of Maintenance

Maintenance of assembled steel sections is relatively simple, making it the preferred choice for structures that require regular inspection and maintenance.

Applications Of Buit Up Steel Sections

Applications of the assembled steel part

Assembled steel structures have many applications in different industries:

1. Construction Industry

They are widely used in the construction of bridges, high-rise buildings, stadiums and industrial facilities where their strength and versatility are put to good use.

2. Automobile

In the automotive industry, cast steel is used to manufacture heavy-duty vehicles, such as trucks and buses.

3. Machinery And Equipment

Many machines and equipment used in factories and manufacturing plants incorporate steel sections that are joined together due to their load-carrying capacity.

4. Furniture

Some types of furniture, such as sturdy tables and chairs, also use engineered steel sections to provide stability and support.

Closing Thought

Cast steel sections are very useful engineering technique that have revolutionized the construction industry.

With their exceptional strength, flexibility and cost-effectiveness, they have become an integral part of modern infrastructure and architectural marvels.

Read Also: Difference Between Bridge And Flyover

From towering skyscrapers to iconic bridges, these steel profiles continue to shape the world we live in today.