Table of Contents

What Is Cantilever Beam?

A cantilever beam can be defined as a beam that is supported on only one side. In this way, one end is fixed and the other end is exposed beyond the support. The beam transmits the load to the support where it can manage the moment of force and shear stress. The moment of force is the tendency of a force to twist or rotate an object. Shear stress is characterized as stress which is applied parallel to the face of a material.

In other words, the beam carries a specific weight on its open end as a result of the support on its enclosed end, in addition, to forestall breaking down as a result of the shear stress, the weight would generate on the beam structure. Cantilever construction permits for overhanging structures without external bracing/support pillars. Cantilever beams can also be built with trusses or slabs.

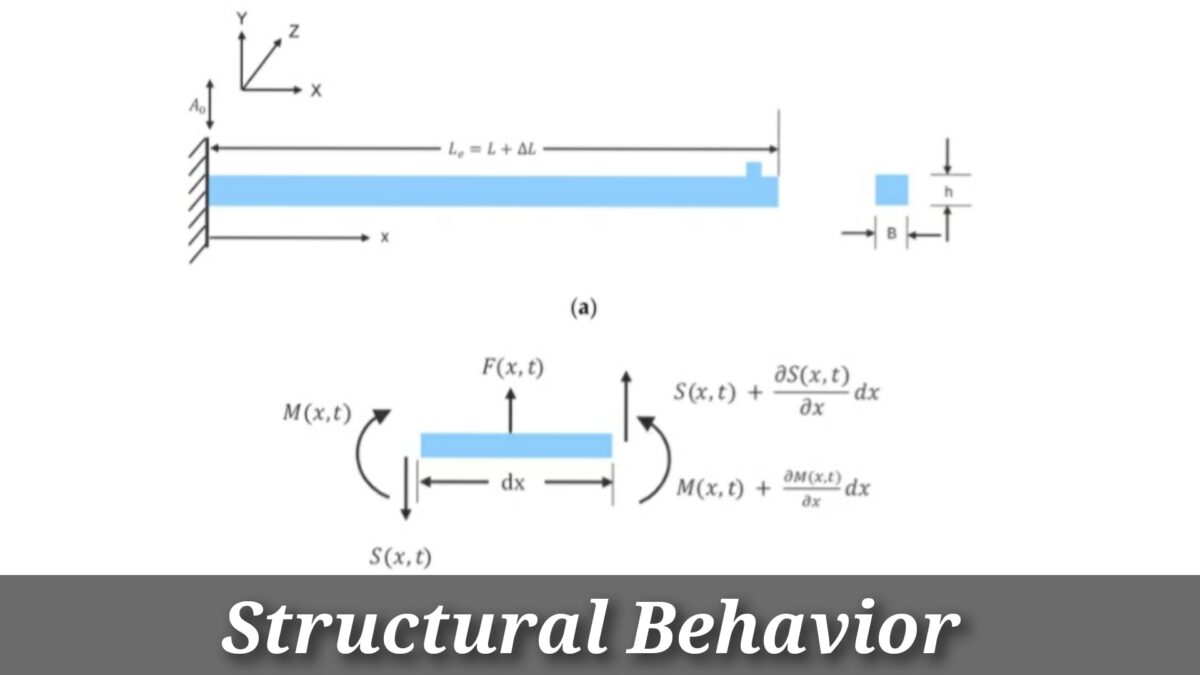

Structural Behavior Due To Applied Load

The cantilever beam bends when a load is applied to its free end, taking on a curved shape.

Shear forces caused by the load can cause the cantilever beam to twist or shear along its length.

Torsion or twisting forces due to the load can cause the cantilever beam to twist around its longitudinal axis.

The amount of bending, shear, and torsion depends on the load magnitude and distribution, beam geometry, and material properties.

Engineers predict the cantilever beam’s structural behavior using mathematical models and simulations to design it to withstand expected loads.

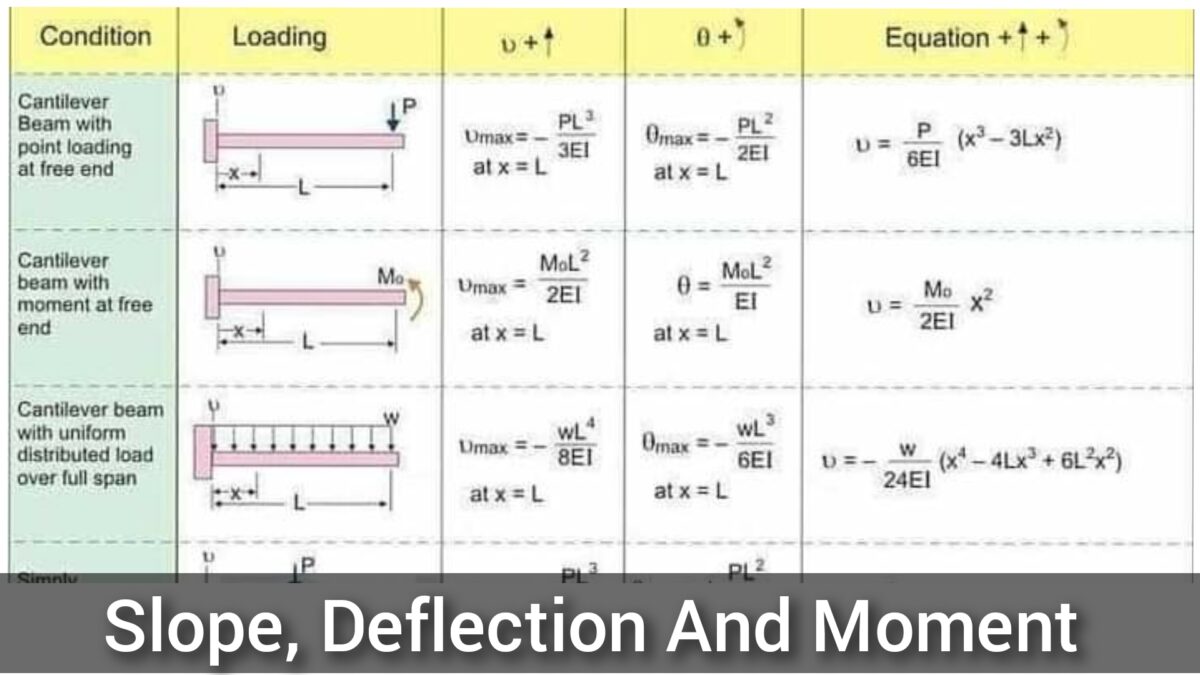

Formulas Of Cantilever Beam

Formulas of slope, deflection and bending moment are shown in the below image:

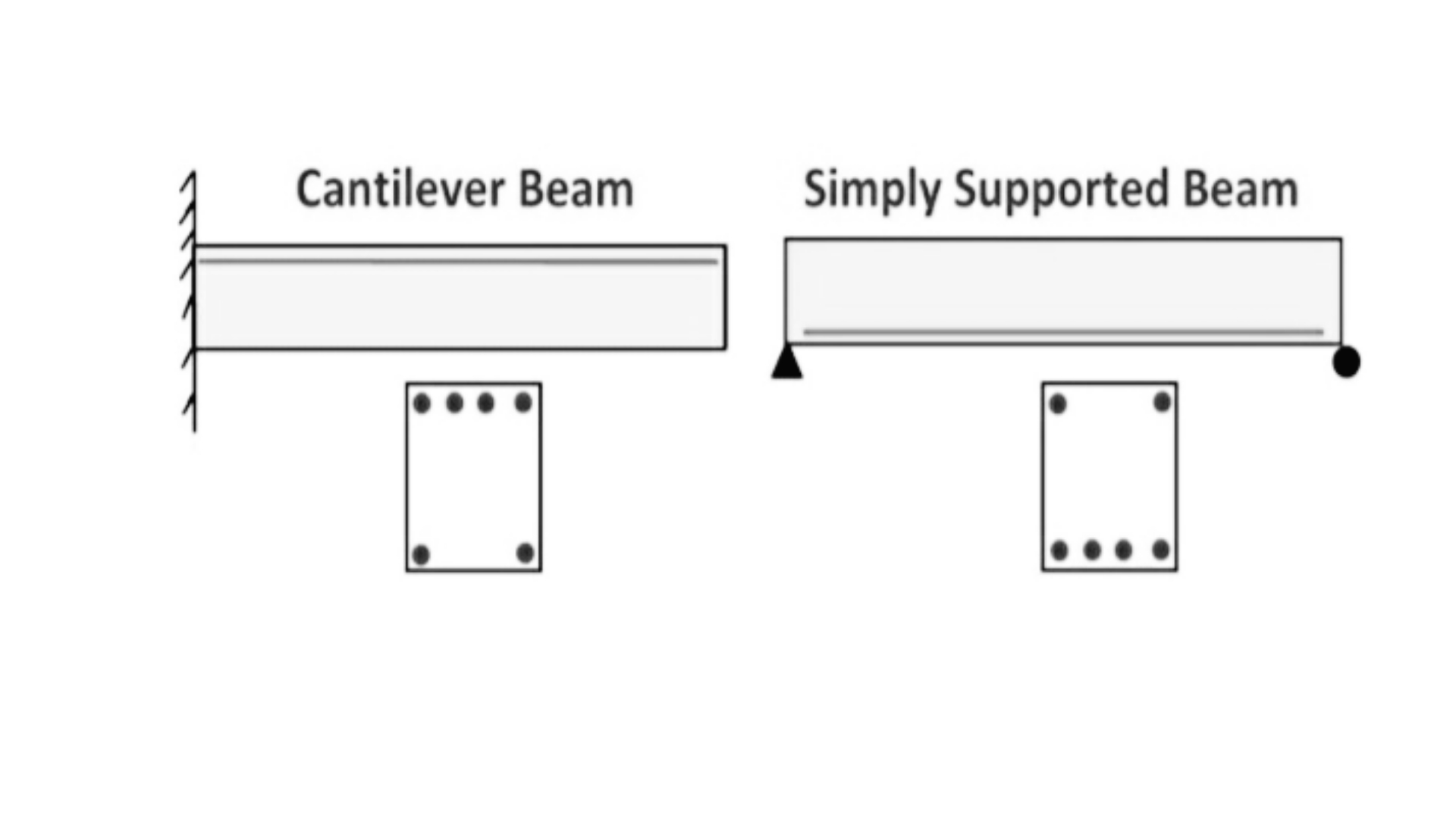

Design Of Cantilever Beam

When designing a cantilever beam, it is important to consider the load that the beam will need to support. The load can be either static or dynamic and could be a uniform or point load. The material properties of the beam, such as modulus of elasticity, yield strength, and ultimate strength, also need to be taken into account.

The load on a cantilever beam induces moment and shear stresses within the beam, which must be safely transferred to the support structure. The bending moment of a cantilever beam varies from zero at the free end to a maximum at the fixed end support. Therefore, major reinforcement is provided to the upper fiber of the concrete beam during the design of cantilever beams to safely bear tensile stress.

The first step in the design process is to determine the maximum deflection of the beam using the load and material properties. The deflection should be limited to a value that is acceptable for the intended use of the beam. Once the maximum deflection is known, the cross-sectional area of the beam can be determined. The cross-sectional area should be large enough to support the load without excessive deflection or failure.

The next step is to determine the beam dimensions, including the height, width, and length of the beam. The dimensions should be chosen such that the beam can support the required load without excessive deflection or failure. The beam should also be checked for buckling, which is a type of failure that occurs when a slender beam is subjected to compressive loads. If the beam is likely to buckle, additional support or stiffeners may be required.

Designing a cantilever beam requires careful consideration of the loads and stresses involved, as well as the properties of the material used to construct the beam. It is recommended to consult with an engineer or use appropriate software for accurate and safe design.

Applications Of Cantilever Beam

1. Construction

Cantilever beams are commonly used in the construction industry to support large structures such as bridges, buildings, and dams. In these applications, the cantilever beam is often used to support a portion of the structure that is cantilevered out over a river or valley. The beam is designed to withstand the weight of the structure and any additional loads, such as wind or seismic forces, that may act upon it.

2. Manufacturing

In manufacturing, cantilever beams are often used as support structures for heavy machinery and equipment. The beam is designed to support the weight of the machinery and any additional loads that may be placed on it during operation. This allows for a stable and secure base for the machinery, which is essential for ensuring its proper function and longevity.

3. Aerospace

Cantilever beams are also used in the aerospace industry for the design and construction of aircraft wings. The wings of an aircraft are designed as cantilever beams, with the weight of the aircraft being supported by the wings. The beams are designed to withstand the stresses and forces that are generated during flight, including lift, drag, and turbulence.

4. Medical devices

Cantilever beams are used in medical devices, such as atomic force microscopes, which are used to study and manipulate biological systems at the molecular level. In these applications, the cantilever beam is used as a probe to measure the mechanical properties of cells and tissues.

5. Electronics

Cantilever beams are also used in the field of electronics, particularly in the design and manufacture of microelectromechanical systems (MEMS). MEMS devices are made up of tiny cantilever beams that are used to measure and manipulate electrical signals on a microscale level. These devices are used in a variety of applications, including sensors, actuators, and microphones.

6. Sports

Cantilever beams are used in the design and construction of sports equipment, such as skis and snowboards. The beams are used to provide flexibility and support to the equipment, allowing it to absorb shocks and vibrations during use. In addition, cantilever beams are used in the design of diving boards and high diving platforms, providing a stable and secure platform for athletes to perform their routines.

Advantages Of Cantilever Beam:

- Very easy and simple to construct.

- Only one fixed support is needed, support on the opposite side is not required.

- These types of beams create a negative bending moment, which can assist to counteract a positive bending moment created elsewhere. This is especially helpful in cantilevers with a back span where a uniform load on the back span creates positive bending, but a uniform load on the cantilever creates negative bending.

- The span can be more than that of a simple beam because a beam can be added to the cantilever arms.

- Because the beam is resting simply on the arms, thermal expansion and ground movement are reasonably simple to sustain.

- Cantilever beams are very stiff, due to their depth.

Disadvantages Of Cantilever Beam:

- Large deflections occur.

- Mostly results in larger moments.

- You either require to have fixed support, or have a back span and check for the uplift of the far support.

- when the beam is loaded at one end, the moment at the fixed end is higher, if more load is applied, it can break free from the support.