Table of Contents

Dewatering Definition

Dewatering means removing water or moisture from a material or site.

People can use different techniques like filtering, settling, or drying to dewater something.

Construction workers often dewater trenches, excavations, or foundations to make a dry work environment.

Industrial workers use dewatering to remove water from wastewater, sludge, or other materials before disposing or reusing them.

In farming, people use dewatering to remove extra water from fields to improve crop growth.

What Is Dewatering

Dewatering is the Procedure of removing water from an excavation. In this operation, the water is drained outside by pumping from the location.

The chief purpose of dewatering is to provide a dry base for the foundation by lowering the groundwater table of a given location. Dewatering is a useful technique for dealing with running sand, construction as well as repairing dams, sewers, basements, buildings, tunnels, etc.

Purpose

- We use dewatering to remove water from a construction site or excavation.

- Dewatering makes the soil or excavation site stronger and safer for work.

- We use dewatering to prevent flooding and protect property.

- Dewatering can help with construction work like laying foundations or installing utilities.

- We can also use dewatering to recover valuable materials from liquids or slurries.

Methods Of Dewatering:

There are generally four techniques of dewatering which are listed below:

- Well Point method.

- Eductor Wells.

- Open Sump Pumping.

- Deep Well Point method.

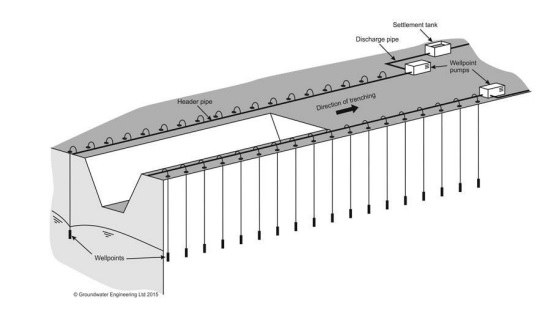

1. Well Point Method

A series of wells are designed along the excavated area.

Well points are connected to riser pipes and they, in turn, are connected to a common header pipe and a vacuum pump. Water is then discharged away from the site.

Wellpoint method uses suction, so it’s suitable for depths up to 5 to 6 meters

In short, the more depth, the greater number of good points are required.

2. Eductor wells

They are similar to the well point method.

Eductor wells use high-pressure water instead of vacuum to draw water from well points.

High-pressure water is circulated through eductors thus creating a reduction in pressure. The pressure drop draws water from the riser pipe.

Thus, using eductor wells can lower the depth of the water table level in the range of 10m to 45m.

The biggest advantage of eductor wells is the efficiency of these pumps as multiple pumps can operate in a single station.

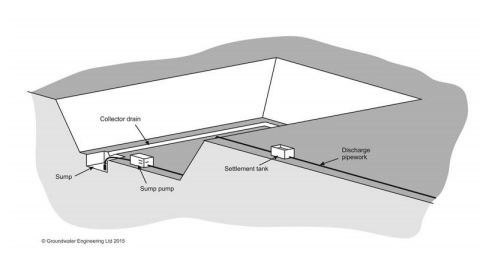

3. Open Sump Pumping

They are the most common method for dewatering. This pump basically works on gravity.

It’s used in shallow excavation areas where the soil has a high content of sand and gravel.

In short, the groundwater is allowed to seep into the excavation area, where it is collected into sumps and then pumped out using sump pumps.

4. Deep Well Point Method

Uses boreholes with submersible pumps in order to lower the groundwater below the excavation level.

Well with diameters of 15cm-20cm are drilled around the excavated area where the groundwater levels fall due to gravity and thus this reduces the water table.

Casings are used to retain the walls. This method is used often in construction sites located near marine bodies where a large amount of water is supposed to be removed.

Types

I have explained some common types of dewatering techniques used in construction industry.

1. Gravity Drainage:

This is the simplest and most cost-effective method of dewatering. It involves allowing the material to sit in a sloping basin or trench, where the water drains naturally by gravity.

2. Filtration:

In this method, the material is passed through a filter, which removes the water by forcing it through a porous medium. This can be done using filter presses, belt filters, or vacuum filters.

3. Centrifugation:

This method involves spinning the material in a centrifuge, which separates the water from the solids by creating a centrifugal force. The separated water can then be discharged, while the dewatered solids are collected for disposal or reuse.

4. Drying Beds:

This method involves spreading the material on a bed of sand or gravel, allowing the water to drain through the bed and evaporate. The dewatered material is then removed from the bed for disposal or reuse.

5. Thermal Drying:

This method involves heating the material to evaporate the water. This is commonly used for sewage sludge, where the material is dried in large ovens or kilns.

Precautions For Dewatering:

- The water should not be pumped directly into slopes.

- A wooded buffer should be utilized in dewatering, if possible.

- Dewatering should be done under special supervision, if any signs of erosion or instability found, halt dewatering instantly.

- Channels to be utilized on dewatering must be stable and protected with grass or vegetation.

- Always avoid dewatering under heavy rains.

- Water contaminated with oil, grease, chemical products should not be released directly. In such cases, an oil/water separator can be utilized.

- Check and understand the water table condition of the location, because the underground water may be situated near the surface so the plan may not work.

Advantages:

- Dewatering improves stability by reducing water content, making materials less prone to liquefaction, erosion, or landslides.

- Dewatering speeds up construction by allowing faster excavation, foundation, or underground work, and reduces the need for soil replacement.

- Dewatering saves construction costs by reducing the volume of materials to be removed, transported, or disposed of, and reduces the need for reinforcement or stabilization.

- Dewatering improves safety on construction sites by reducing the risk of accidents related to unstable or flooded soil, such as slips, falls, or collapse.

- Dewatering protects the environment by preventing soil erosion, contamination, or waterlogging, as well as enabling better management of stormwater runoff.

- Dewatering improves the quality of soil by reducing its porosity, increasing its density, or enhancing its permeability, which promotes plant growth and reduces erosion.

- Dewatering enables more efficient use of land by reducing the need for costly excavation or fill material, as well as enabling construction or development on previously unusable or unstable areas.

- Dewatering improves the drainage of waterlogged areas by reducing the water table, which reduces the risk of flooding or ponding.

- Dewatering enhances the durability of structures by reducing the moisture content of the soil or other materials, preventing corrosion, decay, or damage caused by freeze-thaw cycles.

- Dewatering enables better quality control of soil or other materials by providing a more uniform and predictable composition, improving the performance and longevity of structures.

Disadvantages:

- Dewatering can be expensive, especially if large volumes of water need to be removed or if specialized equipment is required.

- Dewatering can have negative environmental impacts if not properly managed, such as depleting groundwater, disturbing wildlife, or releasing contaminated water.

- Dewatering causes site disturbance, such as removing vegetation or disrupting soil structure, negatively impacting soil quality, erosion, or wildlife.

- Dewatering reduces the availability of water for other purposes, such as drinking, irrigation, or industrial use, especially in water-scarce areas.

- Dewatering equipment can malfunction, causing delays or accidents, and may require frequent maintenance or replacement.