Diaphragm in structure is a vital element in the field of structural engineering, providing versatility in design and material selection to ensure structural stability and integrity in a variety of architectural settings, as well as transmitting lateral forces to vertical resisting elements.

Table of Contents

What Is Diaphragm In Structure?

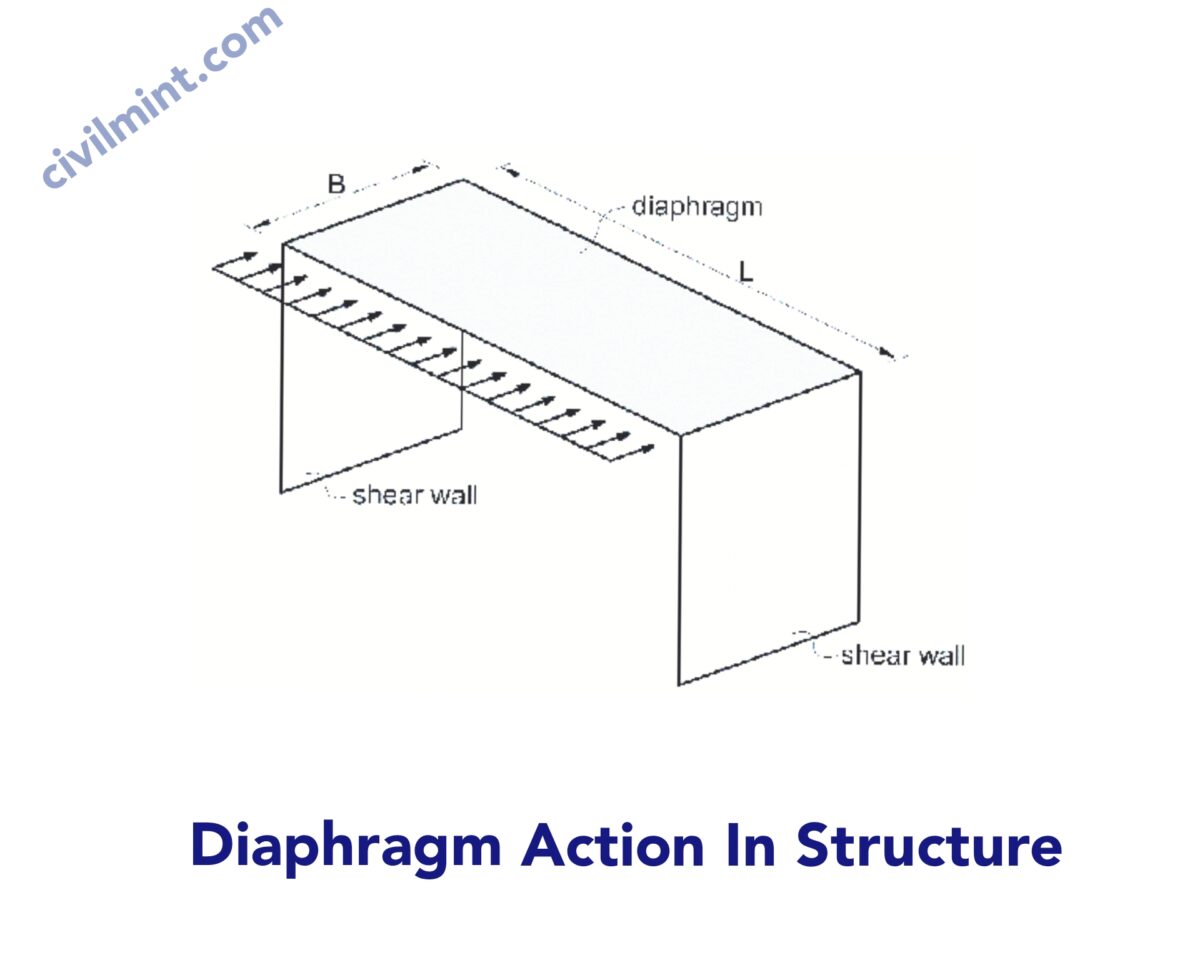

A diaphragm serves as a critical component in a structure that efficiently transmits lateral forces to vertical resisting elements within a building or other architectural constructions, such as shear walls or frames. These diaphragms are primarily located horizontally, but can exhibit sloped configurations, such as in the gable roof of a wooden structure or in concrete ramps within a parking garage. Their primary function is to transfer diaphragm forces to vertical resistive elements primarily through in-plane shear stress.

The primary motivation for the deployment of diaphragms in structures is to effectively combat lateral loads arising from a variety of sources, with wind and earthquake activities being the most prevalent. However, diaphragms can also bear the responsibility of resisting other lateral forces such as lateral earth pressure or hydrostatic pressure through their internal diaphragm action.

Diaphragms often serve a dual purpose, acting as the foundational floor or roof system within a building or the foundational deck in a bridge, as well as supporting the weight of gravity loads.

Diversity characterizes the construction materials employed in diaphragms, with wood construction often using plywood or oriented strand board, steel construction using metal decks or composite metal decks, and concrete construction using concrete slabs.

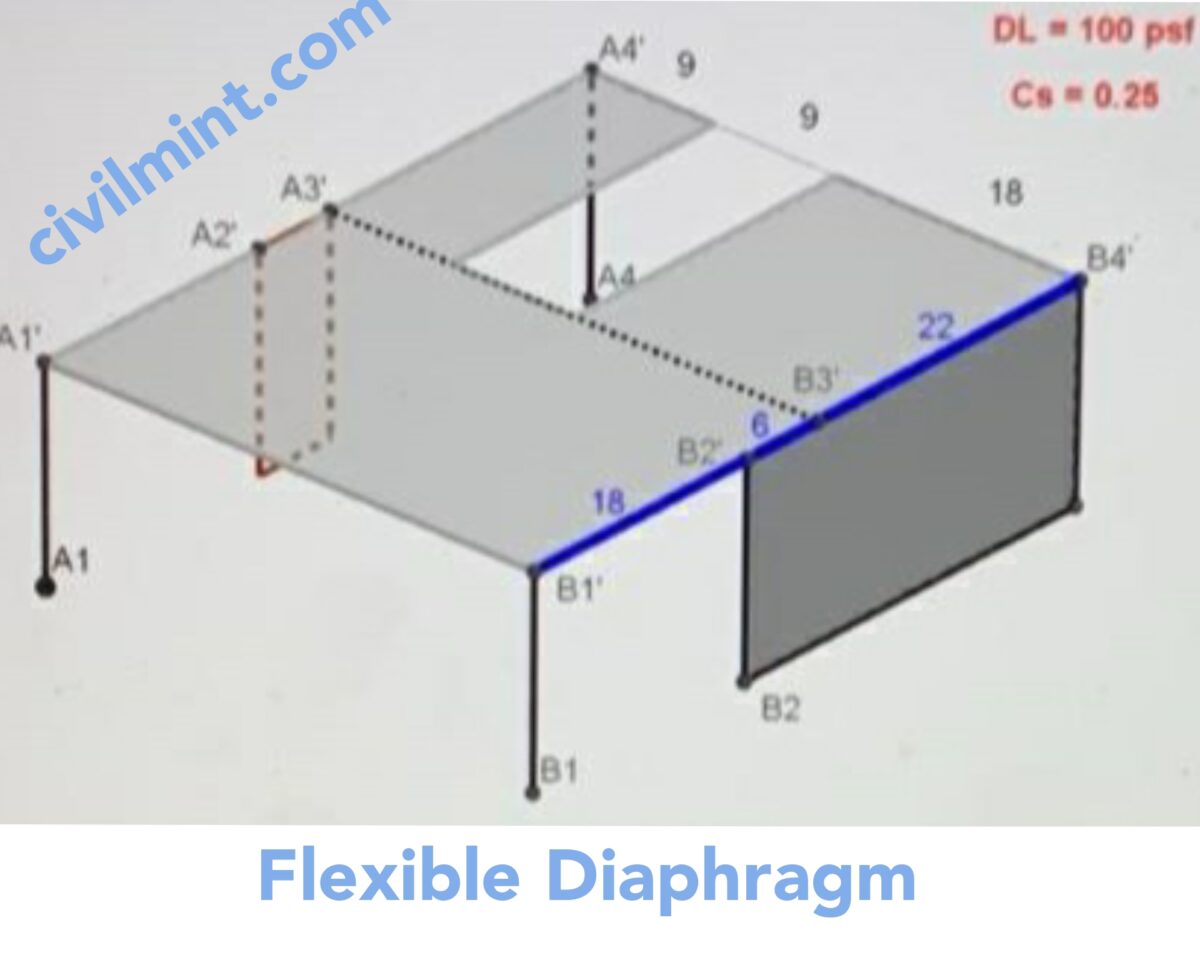

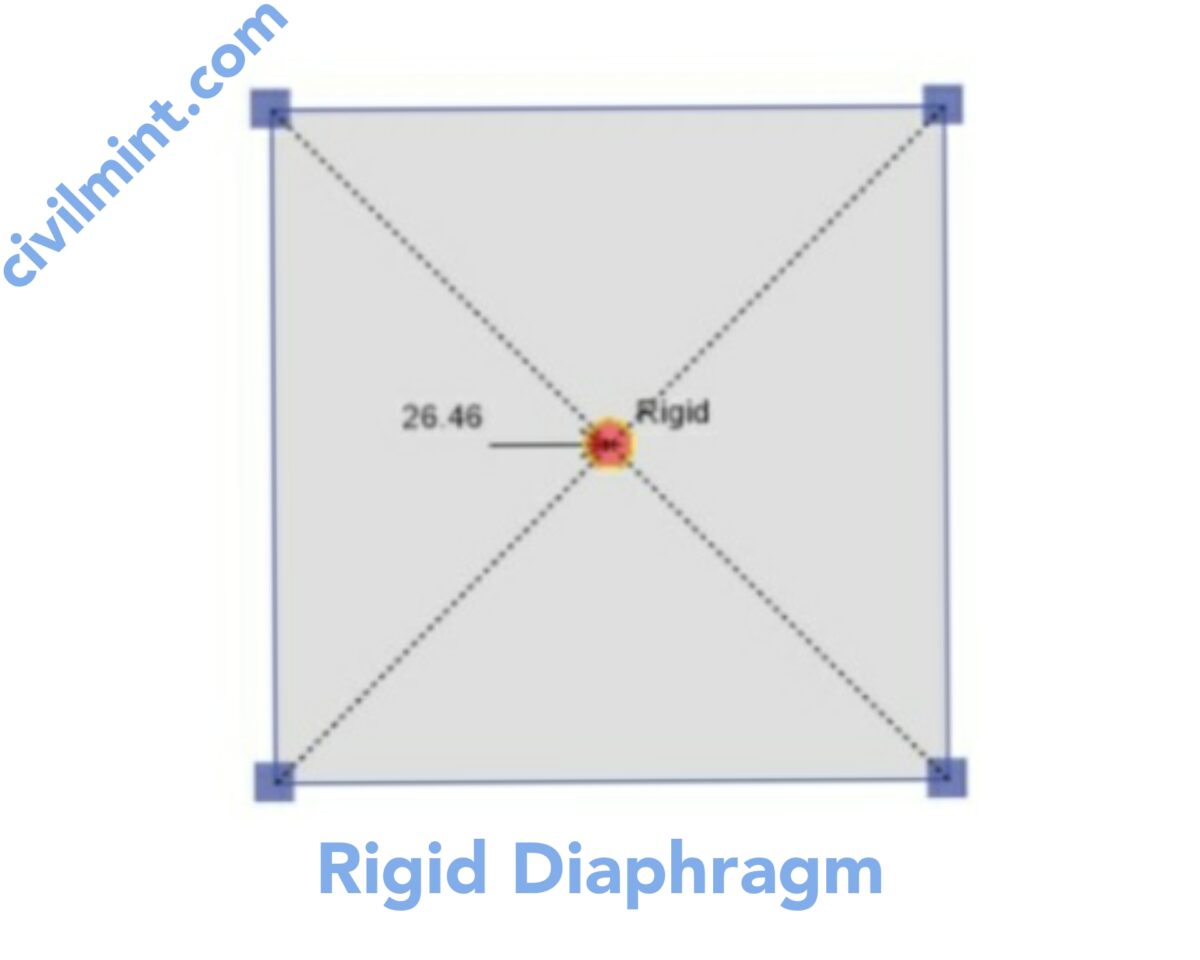

Two basic categories of diaphragms exist: flexible and rigid. Flexible diaphragms resist lateral forces depending on their supporting area, regardless of the flexibility of the members to which they are transmitting forces. In contrast, rigid diaphragms distribute the load to the frame or shear walls based on their inherent flexibility and their position within the structural framework. The ductility of a diaphragm significantly affects how lateral forces are distributed among the vertical components of the lateral force-resisting elements in a structure.

The major components of the diaphragm are the membrane surround, which acts as a shear panel, effectively bearing the shear stresses in the plane, the drag strut member, responsible for transferring the load to the shear walls or frames , and chord, which resists the tension and compression forces that arise within the diaphragm because the membrane generally lacks the ability to manage these loads independently.

Why We Provide Diaphragm In A Structure

It is very important for a structural engineer to know why we provide diaphragms in a structure. Diaphragms are usually provided in high-rise building structures. Here are the main reasons for providing diaphragms in structures.

- Lateral Load Resistance: Diaphragms help a structure resist lateral loads, such as wind and seismic forces. They distribute these forces across the structure, preventing excessive deformation or failure.

- Stiffness and Stability: Diaphragms add stiffness to a structure, enhancing its overall stability. This is crucial for maintaining the integrity of the structure during various loading conditions.

- Load Transfer: They facilitate the transfer of loads from one part of the structure to another. For example, in buildings, diaphragms transfer lateral loads from the roof or floors to the vertical elements like walls and columns.

- Reduction of P-Delta Effects: In tall buildings, diaphragms can help reduce the P-Delta effect, which is a phenomenon where vertical loads induce additional lateral loads due to structural deformations. Diaphragms distribute these loads efficiently.

- Serviceability: Diaphragms help control deflections and vibrations within acceptable limits, ensuring that the structure remains serviceable and comfortable for occupants.

- Uniform Load Distribution: They help distribute uniform loads, such as those from live loads (e.g., occupants, furniture) or dead loads (e.g., building materials), evenly to the supporting elements.

- Seismic Performance: In earthquake-prone regions, diaphragms are critical for the seismic performance of structures. They help dissipate seismic energy and reduce torsional effects.

- Architectural Integration: Diaphragms can be designed to fit seamlessly into the architectural layout of a structure, allowing for open and flexible interior spaces.

- Constructability: Diaphragms can simplify the construction process by providing a level surface for the placement of floors, roofs, and walls.

Types Of Diaphragms In Structural Engineering

1. Flexible Diaphragm

In structural engineering, we have Flexible Diaphragms. These diaphragms don’t have much say in how lateral forces move. They are quite limp compared to the stiff frames of a building. When diaphragms are this flexible, they can’t effectively shift forces between frames. Sometimes, engineers need to add horizontal braces to give forces a path to the frames.

Usually, these flexible diaphragms, like those on metal roof decks, use a simple method to distribute lateral loads to frames. It’s based on how much each frame is exposed (for wind) or its area (for seismic). But here’s the catch: these diaphragms aren’t explicitly part of the model. The model only considers the frame members. So, engineers have to assign loads directly to the frames. This is how things were done before fancy 3D programs came along.

2. Rigid Diaphragm

Now, let’s talk about Rigid Diaphragms. These are the opposite of flexible ones. They are very stiff compared to the frames. When you push them laterally, they hardly budge. To make things simpler in calculations, engineers often pretend that the diaphragm is super rigid, even though it can still rotate and move a bit. This trick reduces the complexity of the model significantly.

In this rigid diaphragm model, lateral forces get distributed based on how stiff the different frame members are. This works well for concrete floors and metal deck floors, which are known for being very stiff. It’s a handy tool for connecting frames and making sure the story forces spread out nicely.

3. Semirigid Diaphragm

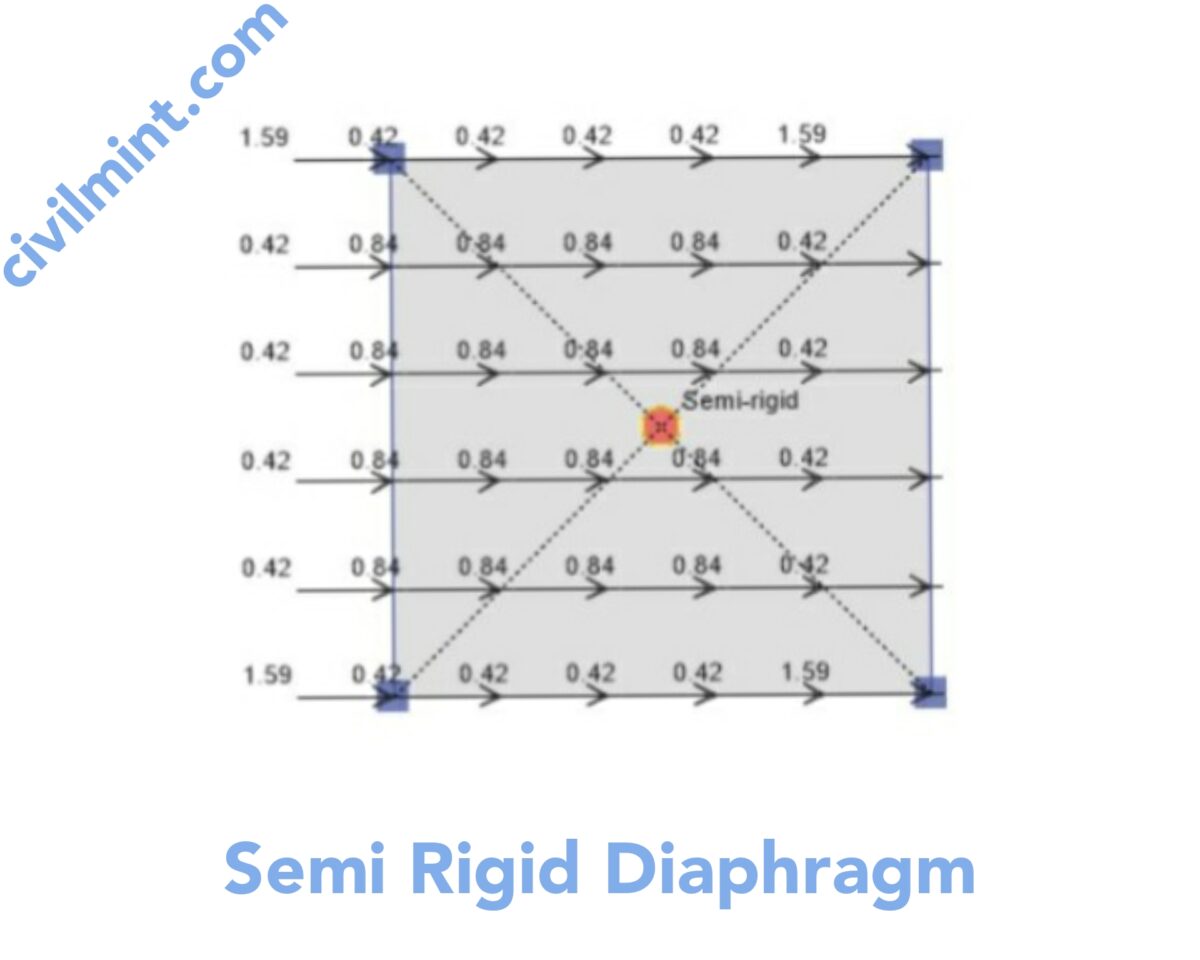

Then, there are Semirigid Diaphragms. These fall in the middle ground. They’re not as floppy as flexible ones but not as stiff as rigid ones either. With semirigid diaphragms, how they deform plays a significant role in how lateral forces move within a structure.

To deal with these effects properly, engineers have to model the diaphragm explicitly. This means they have to define the diaphragm’s stiffness and create a detailed model with shell or plate elements. Doing this makes the analytical model much larger and the analysis takes more time. In the past, this was tough due to computer limitations, but today’s computers can handle it.

Conclusion

The diaphragm actively collects and transfers translation or rotational forces resulting from the distribution of shear forces to the lateral resisting vertical system, such as shear walls or frame systems. The connections between the diaphragm and the lateral resisting system consistently remain, as does the spacing between them.

Read this: Shear Wall

Additionally, diaphragms actively unify the structure, enabling it to function as a single entity during an earthquake. The performance of these diaphragms significantly influences the structural integrity and redundancy of a building.