A double pipe heat exchanger is a sort of heat exchanger which includes concentric pipes parted through a mechanical closure. The name of this heat exchanger indicates that it makes use of pipes to exchange heat among fluids. One pipe has hot fluid whilst the opposite pipe has cold fluid. These two fluids do not mix with each other as they are separated by pipes. This heat exchanger is likewise known as a jacketed u-tube, jacketed tube, hairpin, and pipe-in-pipe heat exchanger.

The double pipe heat exchanger has a small pipe this is surrounded by some other huge pipes. One fluid glide withinside the small pipe, and the opposite fluid acts through the annulus among the 2 pipes. The internal wall of the small pipe is the heat switch surface. The complete warmness switch system takes vicinity withinside the huge tube. In this way, the internal pipe works as a conductive barrier. The outside facet consists of fluid gliding thru the tube facet or inside. This heat exchanger might also additionally have one pipe or a package deal of pipes (however decrease than 30 pipes). The huge pipe has decreased by 2 hundred mm in diameter. In a few conditions, the internal pipe has vertical fins to enhance the heat switch coefficient among operating fluids.

Double pipe heat exchangers are used for small heat switch areas (e.g., 14 m2). The collection connection to elevate the heat switch place wishes greater area and greater accessories, which results in a better strain loss. In addition, it isn’t always viable to boom the number of fluid passages on each side. This heat exchanger isn’t always exceptionally appropriate for grimy drinks due to the fact the grimy liquid will clog it, and the cleansing of this exchanger could be very hard. The essential benefit of the double pipe warmness exchanger is that it has a smooth operation and easy design.

The production price of the double tube warmness exchanger is pretty low and calls for minimal maintenance. These exchangers are exceptional for realistic cooling or heating in high-strain and high-temperature applications.

Table of Contents

Configuration of Double Pipe Heat Exchangers

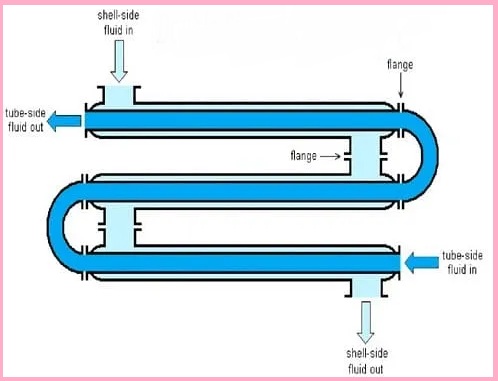

Double tube heat exchangers are one of the simplest types of heat exchangers. The figure below shows this heat exchanger. One shell or tube is surrounded by another shell or tube, as shown in the figure below. These types of shell and tube heat exchangers have a simple and well-designed design and offer a wide range of options for customers to choose a heat exchanger according to their needs. There are several custom heat exchangers on the market designed to meet the needs of different industries and projects. A double tube heat exchanger is recommended for use in small applications. They are used to transfer heat in a small area (ie less than 45 square meters).

To use this exchanger, you need to know the type of liquid in your system. Due to the large flow space on the shell side, only viscous liquids can be used on the shell side. Therefore, when using steam as the working medium for heat exchangers, it is best to use tubes for the flow.

Before choosing the right heat exchanger, you need to determine the characteristics or conditions of your project. You also need to determine the outlet and inlet temperatures and the required heat transfer coefficient. With this information, you and your sales representative can easily introduce you to a commercial exchanger and design a suitable pair of tubes for your exchanger.

As mentioned earlier, double tube heat exchangers are modular and simple in construction, but it should be remembered that increasing the surface area increases the cost of the heat exchanger. If you want to buy a heat exchanger to transfer heat over a large area, you have to pay a lot of money for a heat exchanger.

Different Types of Double Pipe Heat Exchangers

There are two types of double pipe heat exchangers as follows:

- Counter flow heat exchanger

- Parallel flow heat exchanger

Let’s get some idea about these two types of heat exchangers.

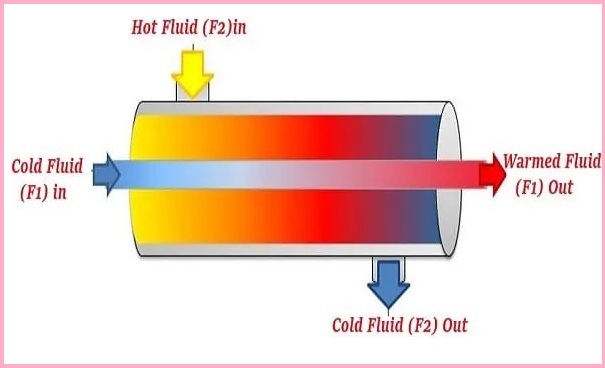

1. Counter flow Double Pipe Heat Exchanger

This type of heat exchanger is one of the double tube heat exchangers. In a Counter flow heat exchanger, one working medium has a flow direction opposite to the flow direction of the other working medium. With this design, the heat exchanger has the highest heat transfer coefficient and the outlets can be easily heated or cooled as needed.

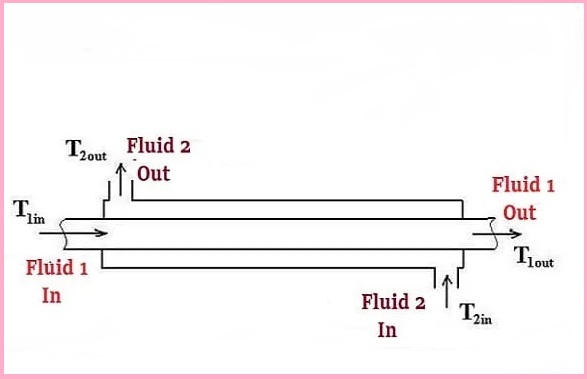

The figure above shows the location of the outlet and inlet. As shown in the figure, the liquid flows in opposite directions and the liquid has the maximum temperature difference at the ends of both heads. Looking at the figure above, imagine that Liquid 1 is hot and Liquid 2 is cold. The cold end temperature at the outlet (T2out) can reach near the inlet temperature (T1in). As you know, the temperature on the inlet side (T1in) is higher than that on the outlet side (T1out). However, in the case of Counter flow heat exchangers, the temperature of the fluid on the cold side can be higher than the temperature of the outlet on the hot side. This is not possible with parallel flow heat exchangers.

The maximum shell and tube heat exchangers are Counter flow designs as this is one of the most effective designs. The Counter flow design allows for maximum temperature changes between hydraulic fluids.

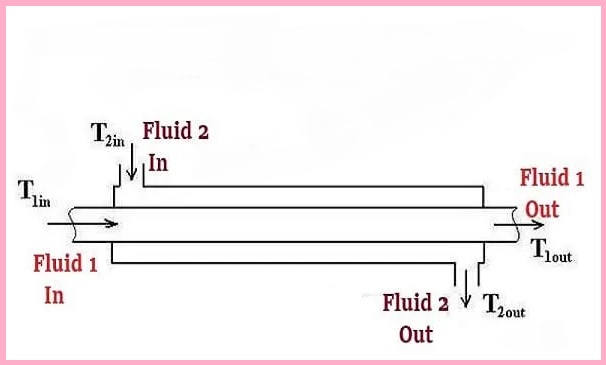

2. Parallel flow heat exchanger

As the name of the parallel heat exchanger indicates, each fluid goes with the drift in this heat exchanger. Parallel flow double tube heat exchangers have the same direction with respect to the inlet and outlet liquids. This heat exchanger design is less efficient and has a lower heat transfer coefficient than the counterflow design. However, certain applications require this parallel design.

Advantages of Double Pipe Heat Exchanger

- Double tube heat exchangers are low-cost.

- Great efficiency can be achieved with a very low cost of capital

- These heat exchangers are smaller in size than shell and tube heat exchangers.

- You don’t need a lot of space.

- It has lower maintenance costs than shell and tube heat exchangers.

- Easy assembly and parts replacement.

- These exchanges have a simple and compact structure.

- This heat exchanger is also ideal for high-pressure and high-temperature applications such as compressors and boilers.

- These heat exchangers are so popular that they all use standardized parts and are easy to maintain and repair.

- The structure of these heat exchangers allows for greater thermal expansion without expanding the joint.

Disadvantages of Double Pipe Heat Exchanger

- Double tube heat exchangers have lower tubes than shell and tube heat exchangers. This means that it has a lower heat transfer coefficient than shell and tube heat exchangers.

- Not available in the crossflow version. Therefore, these exchanges cannot be used for any particular application.

- Adding units increases the likelihood of leaks due to the increased number of connections.

- There is a high probability of leaks on remote connections.

- These heat exchangers have limited heat transfer and can be used for small area applications.

Applications and Uses of Double Pipe Heat Exchanger

- Double tube heat exchangers are used in compressors and boilers due to their extremely high pressure and temperature.

- Process plant cooling and heating system.

- Wastewater treatment

- cooling

- Petroleum refining