Table of Contents

What Is Elastomeric Bearing?

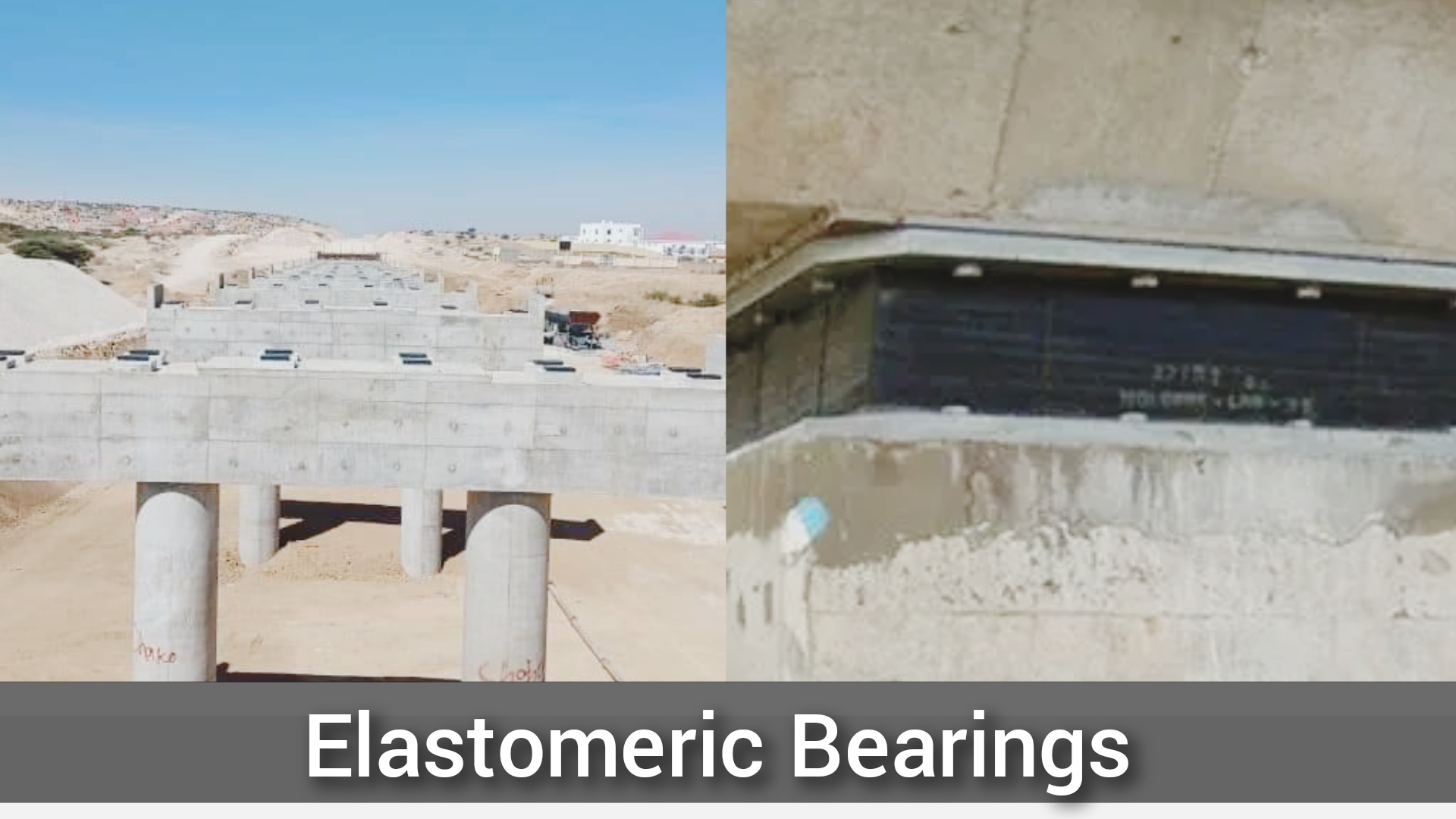

Elastomeric bearing is widely used in modern bridge construction. It is also called as pot bearing. They are a type of bridge bearing pad, which also includes laminated elastomeric bearings, seismic isolators, and bearing pads. These pads are used to support heavy structures such as bridge beams, allowing for slight horizontal movement relative to the ground or foundation. Without such bearings, ground movements or thermal expansion and contraction can cause bridge supports to crack or fracture.

Elastomeric bearing pads consist of three layers: a lower steel pot that rests on the foundation or footing, a relatively thin elastomeric pad that sits on the lower pot, and a steel plate that supports the weight of the bridge and is loosely placed on top of the elastomeric disk. These bearings are often manufactured as a single unit, ready for installation.

Manufacturers use various materials to make elastomeric pads, including natural rubber, elastomers, Teflon, or synthetic rubber such as neoprene. They are a cost-effective solution for the construction of large span bridges and buildings.

Elastomeric bearings are not limited to bridges and can also support buildings that are built on soil that may shift slightly, which can cause concrete loads to crack in the absence of an elastomeric bearing.

Design Considerations

The engineers construct elastomeric bearings to provide support to structures while also allowing for movement and flexibility. These bearings consist of multiple layers of rubber and steel plates that they bond together. Generally, natural or synthetic rubber layers are utilized to provide the necessary flexibility and damping characteristics, while steel plates supply the required load-carrying capacity and stability.

The basic design of an elastomeric bearing comprises a sequence of rubber layers positioned between steel plates. The rubber layers deform under load, and the steel plates distribute the load evenly across them. Engineers bond the rubber layers to the steel plates using various methods such as adhesives, vulcanization, and compression molding.

Elastomeric bearings are designed to adjust to movement and flexibility in two primary ways. Firstly, the bearing absorbs shocks and vibrations as the rubber layers deform under load. Secondly, the bearing can adjust to horizontal movement and rotation as the rubber layers move laterally.

Advantages Of Elastomeric Bearing

1. Shock and vibration absorption:

Elastomeric bearings can absorb shocks and vibrations, making them an ideal choice for structures that require stability and vibration control.

2. Easy installation and maintenance:

Compared to other types of structural bearings, elastomeric bearings are relatively easy to install and maintain, saving time and money over the life of the structure.

3. Cost-effective:

Elastomeric bearings are generally less expensive than other types of structural bearings, making them a cost-effective choice for many projects.

4. Good durability:

Elastomeric bearings are designed to last for many years, even in harsh environments. They can resist corrosion, impact, and other types of damage.

5. Low noise transmission:

Elastomeric bearings can reduce noise transmission between the structure and its foundation, improving the comfort and safety of occupants.

Disadvantages Of Elastomeric Bearing

1. UV and ozone susceptibility:

Elastomeric bearings can be damaged by UV radiation and ozone exposure over time, which can degrade the rubber layers and reduce their stability and load-carrying capacity.

2. Limited movement and rotation:

Elastomeric bearings are not suitable for applications where large movements or rotations are required. They have a limited range of movement and are best suited for structures with relatively small deflections.

3. Temperature sensitivity:

Elastomeric bearings may experience changes in their properties and performance at extreme temperatures, which can affect their ability to support the structure. Proper selection of elastomeric materials and design is necessary to ensure their performance in different temperature ranges.

Applications And Uses

Elastomeric bearings play a crucial role in a wide range of applications, such as bridges, buildings, and industrial equipment. They are known for their ability to provide support, flexibility, stability, and load-carrying capacity.

In bridge construction, engineers use elastomeric bearings to support the weight of the bridge while accommodating movements and rotations caused by traffic loads and temperature changes. Elastomeric bearings are often used in combination with expansion joints to ensure smooth movement and prevent damage to the bridge.

In building construction, elastomeric bearings are used to support heavy loads while allowing for controlled movement and vibration. They are especially useful in seismic applications where they help buildings withstand earthquakes and other seismic events. The elastomeric bearings absorb the seismic energy and prevent damage to the building.

In industrial equipment, elastomeric bearings play a critical role in providing vibration isolation and shock absorption. They help to reduce the impact of machinery vibrations and prevent damage to the equipment. Elastomeric bearings can improve the lifespan of industrial equipment and reduce maintenance costs.

Article Summary

Elastomeric bearings offer a variety of advantages over other types of bearings and play a vital role as a structural bearing. They are designed to provide stability and load-carrying capacity, while offering support, flexibility, and vibration isolation. Engineers commonly use elastomeric bearings in a range of applications, including bridges, buildings, and industrial equipment. Although there are a few disadvantages to using elastomeric bearings, their advantages make them an attractive option for many applications. In summary, elastomeric bearings are a dependable and efficient solution for supporting heavy loads while allowing for movement and flexibility.