In this article we will learn about splicing of reinforcement bars and all the methods of splicing reinforcement bars.

Table of Contents

Splicing Of Reinforcement Bars

Splicing of reinforcement bars is a method of connecting two or more reinforcing bars (rebars) in a reinforced concrete structure to create a continuous and load-resisting structure.

The lap splice is one of the most common types of splices used in reinforced concrete structures, where two lengths of rebar are overlapped and wired together. The overlap length is the most important factor in the strength of the splice, and it depends on the size of the rebar and the specific structural application.

Methods Of Splicing Reinforced Bars

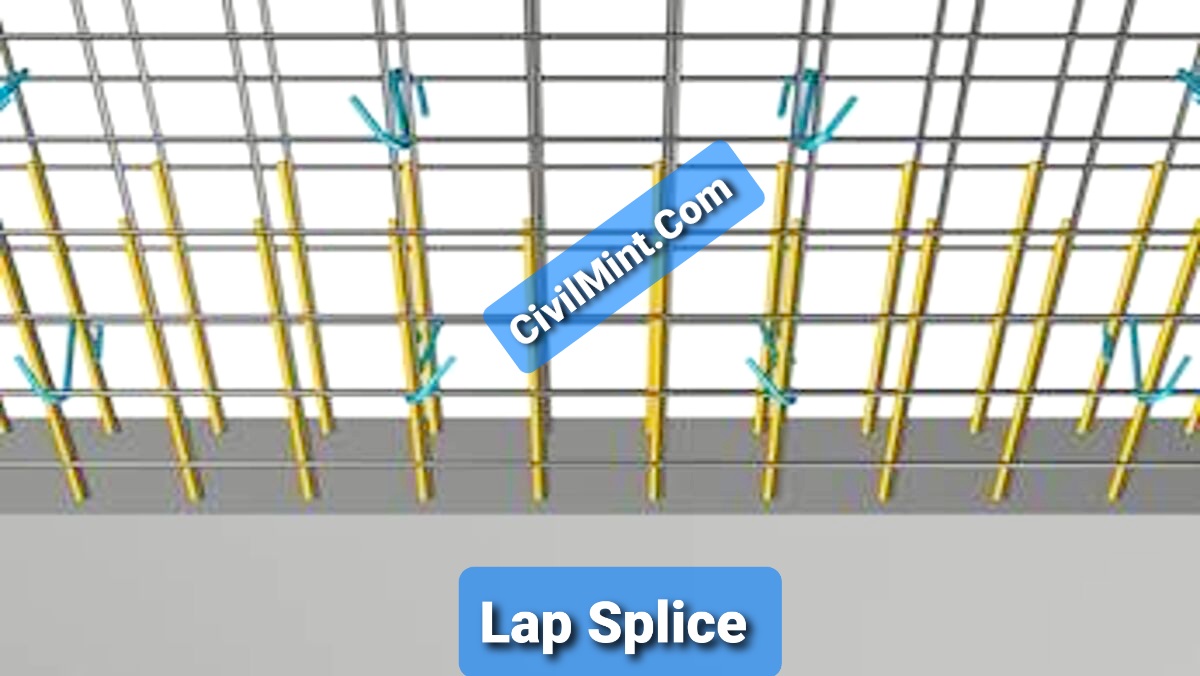

1. Lap Splice:

A lap splice is a method of joining two pieces of material by overlapping them and then fastening them together. This type of splice is commonly used in the woodworking, metal and textile industries.

In woodworking, for example, two pieces of wood are overlapped and glued or screwed together to form a joint. The strength of the joint depends on the length of the overlap and the type of fastener used. A lap splice is relatively easy to make, but it may not be as strong as other types of splices.

2. Mechanical Splice:

A mechanical splice is a type of splice that uses mechanical means to join two pieces of material together. In the case of steel cables, for example, a mechanical joint may use clamps to hold the two ends of the cable together.

The clamp is designed to distribute the load evenly across the splice, and can be tightened to ensure a secure connection. Mechanical splices are commonly used in the construction of bridges, buildings, and other structures where strength and durability are important. They are also used in the telecommunications industry to connect fiber optic cables.

3. Welded Splice:

A welded joint is a type of joint that uses heat and pressure to join two pieces of material together. In welding, the edges of two pieces of material are heated to a high temperature and then pressed together.

As they cool, the materials fuse together, forming a strong bond. Welded splices are commonly used in the construction of metal structures, such as bridges, buildings and pipelines. They are also used in the automotive and aerospace industries to join metal components. Welded rebars can be very strong and durable, but they require special equipment and expertise to make.

Sum Up

These 3 methods mentioned above are most common for joining reinforced bars together. A site engineer and site supervisor must be aware of these methods to perform the job properly.