There are various types of H2S gas detector. H2S gas detector is very important in oil and gas industry. In this blog post, I will describe diffrent types of H2S gas detector.

First, let get brief idea of H2S gas detector.

H2S gas detectors are devices that are used to detect the presence of hydrogen sulfide (H2S) gas in the environment. H2S gas is a colorless, flammable, and highly toxic gas that is commonly found in industries such as oil and gas, mining, and wastewater treatment plants.

H2S gas detectors are crucial safety equipment that helps to detect the presence of this gas in the air and alert workers in case of a gas leak or high concentration of H2S gas.

Let’s know all the types of H2S gas detector.

Table of Contents

1. Fixed H2S Gas Detectors

Fixed H2S gas detectors are installed in a fixed position and are designed to continuously monitor the surrounding air for the presence of H2S gas.

These detectors are commonly used in industrial settings where there is a high risk of H2S gas leaks, such as in oil and gas refineries and wastewater treatment plants.

Fixed H2S gas detectors are connected to a central control panel or computer system, which alerts the workers in case of a gas leak or high concentration of H2S gas.

2. Portable H2S Gas Detectors

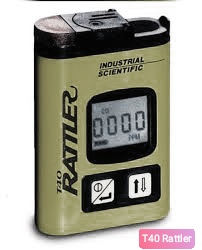

Portable H2S gas detectors are handheld devices that can be carried by workers to different locations within a facility.

These detectors are battery-powered and are designed to detect the presence of H2S gas in the surrounding air.

Portable H2S gas detectors are commonly used by workers in industries such as oil and gas, mining, and wastewater treatment plants, where they may need to move around to different locations to carry out their work.

3. Personal H2S Gas Detectors

Personal H2S gas detectors are wearable devices that are designed to be worn by workers on their clothing or attached to their belt.

These detectors are battery-powered and are designed to monitor the air for the presence of H2S gas. Personal H2S gas detectors are commonly used by workers in industries such as oil and gas, mining, and wastewater treatment plants, where they may be exposed to H2S gas during their work.

4. Fixed and Portable Multi-Gas Detectors

Fixed and portable multi-gas detectors are devices that are designed to detect the presence of multiple gases, including H2S gas.

These detectors are commonly used in industries where workers may be exposed to a variety of gases, such as in oil and gas refineries and chemical plants.

Fixed and portable multi-gas detectors are connected to a central control panel or computer system, which alerts the workers in case of a gas leak or high concentration of any of the gases.

5. Wireless H2S Gas Detectors

Wireless H2S gas detectors are devices that use wireless technology to communicate with a central control panel or computer system.

These detectors are designed to continuously monitor the surrounding air for the presence of H2S gas and can be installed in a fixed position or carried by workers.

Wireless H2S gas detectors are commonly used in industries such as oil and gas, mining, and wastewater treatment plants.

6. Ultrasonic Gas Detectors

Ultrasonic gas detectors are devices that use ultrasonic sound waves to detect the presence of gas in the environment.

These detectors are designed to detect the presence of a variety of gases, including H2S gas. Ultrasonic gas detectors are commonly used in industries such as oil and gas, chemical plants, and power generation plants.

Sum Up

H2S gas detectors are essential safety equipment in industries where workers may be exposed to H2S gas.

The type of H2S gas detector used depends on the industry, application, and the level of risk involved. Regular calibration and maintenance of H2S gas detectors are essential to ensure accurate readings and reliable operation.

Other safety equipment such as gas masks and respirators should also be used to protect workers in the event of a gas leak or high concentration of H2S gas.