Table of Contents

Introduction of Investment Casting

Investment casting is a manufacturing process which uses wax patterns to create disposable ceramic molds. It is also called as precision casting or lost wax casting.

A wax model is made with the exact shape of the item to be cast. This sample is coated with a refractory ceramic material. Once the ceramic material has hardened, turn it upside down and heat until the wax melts and drains. The hardened ceramic shell becomes the recessed mold. The molten metal is poured into a mold and allowed to cool. The cast metal is then removed from the spent mold.

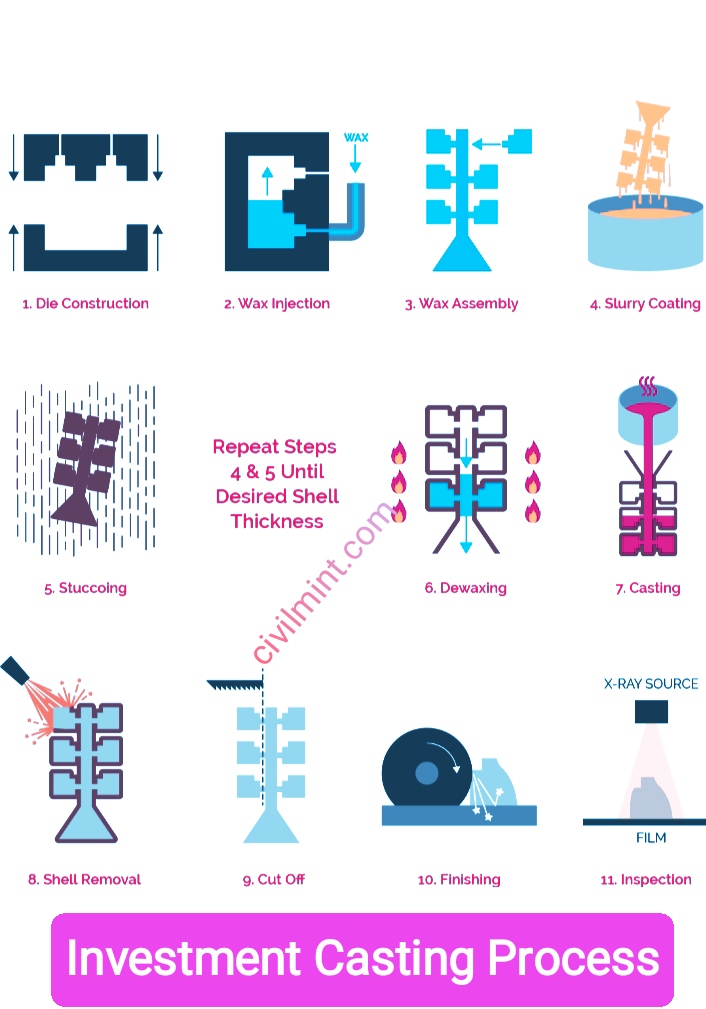

See the below picture of investment casting.

The word investment casting comes from “embedding” (wrapping) the model with refractory material. Investment casting is often preferred over other molding processes because the resulting castings exhibit fine detail and an excellent as-cast surface finish. It can also be cast with thin walls or complex internal passages. Unlike sand casting, investment casting does not require a design.

These process can produce net shape or near net shape castings, resulting in significant savings in materials, labor and machining costs. Most common metals are available, including aluminum, bronze, magnesium, carbon steel, and stainless steel. Investment cast parts include turbine blades, medical devices, firearm parts, gears, jewelry, golf club heads, and many other mechanical parts with complex geometries.

Investment Casting Process

In the first step, a wax pattern is created inside the mold cavity along with a gating system.

Take several such specimens and attach the wood to wax or plastic splints.

The wood is dipped into a ceramic slip. This allows the formation of a self-supporting ceramic shell mold around the wax assembly.

When the ceramic mold shell is heated, the wax melts and flows out, creating a precise mold cavity.

The shell is fired between 850°C and 1000°C to remove all wax and increase the strength of the mold.

Molten metal is poured into a mold while hot to form an ingot.

Finally, break the pottery mold and remove the mold.

I also shown the schematic sketch of investment casting process. Check out the below figure of invest cast process.

Uses of Investment Casting

- It is used to make turbine blades.

- It is used go make artificial components.

- This technology also utilized by firearms.

- Jewellery also made by using invest casting.

- This technology also used in 3-D printing.

Advantages:

- High melting point alloys can be cast using this process.

- Provides high surface finish and dimensional stability.

- In investment casting, the mold is melted away and removed, making it possible to cast complex shapes that are difficult with other casting methods.

- Using this method, thin sections of with fine detail can be cast.

- You can cast multiple parts at the same time.

Cons:

- The process is usually limited by the casting size and mass.

- More expressive than other casting methods.

Conclusion

It was all about investment casting. I hope you got some knowledge regarding investment casting. Thanks for reading my article.

Keep Learning!

GoodBy!