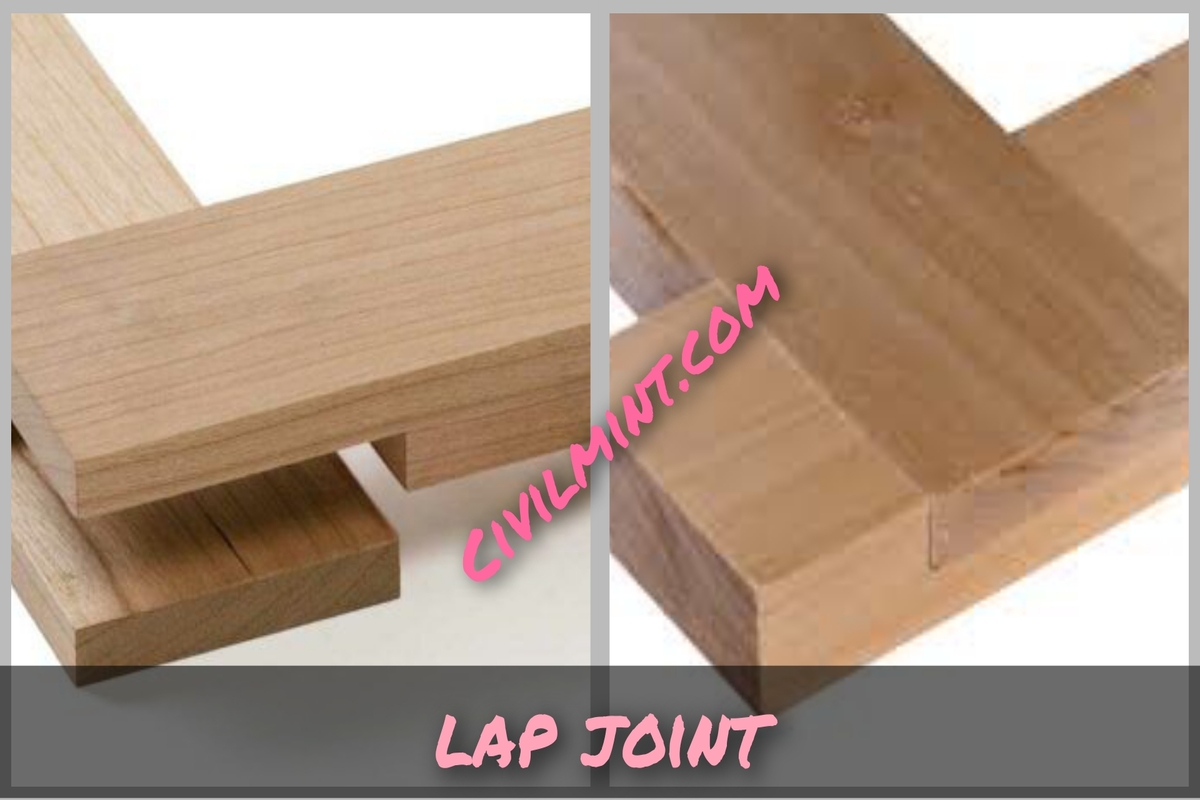

Lap joint is made by lapping two wood pieces together. This type of joint normally used in woodworking industry.

Table of Contents

What Is Lap Joint?

Lap joint is a simple way to join two pieces of wood together. It works by overlapping one piece by another, and then carpenters fasten them using nails, screws, glue or pegs.

The original lap joint is not very strong and can easily break under pressure. Therefore, there are other types of lap joints, such as half lap joints and full lap joints, which are stronger and more stable.

Lap joints are a simple and useful method of joining wood, but they may not be suitable for heavy-duty applications. However, they can be a good option for many DIY projects.

Types Of Lap Joints

I will discuss all the important types of lap joints used in woodworking industry.

1. Basic Lap Joint

In a basic lap joint, the boards are cut to length and lapped over each other, with a few fasteners in the middle to hold them together. None of the wood is removed, and they are easy and quick to make.

2. Half-Lap Joint

A half-lap joint is similar to a basic lap joint, but the carpenter removes half the material from each board before mating them together. The joint takes longer to make, but creates shoulders on both sides of the joint, increasing the surface area for glue and adding some lateral strength.

3. Mitered Lap Joint

A mitered lap joint is a more advanced technique and is very strong. In this joint, the carpenter or woodworker cuts a 45-degree angle on one board, removes half the thickness from the mitered section, and then cuts a 45-degree angle halfway through the other board, creating a corresponding space. When the two mitered angles touch, the joint creates a shoulder, a mitered face, and lots of glue area.

4. Cross-Lap Joint

In a cross-lap joint, the woodworker removes half the material from both boards, creating a half-lap joint in the middle of one or two of the boards. This creates four shoulders and plenty of surface area for wood glue or construction adhesive. The cross-lap joint is extremely strong and popular in woodworking, furniture building, and door construction.

5. Dovetail Lap Joint

The lapped dovetail joint is very similar to the cross-lap joint, except it almost always occurs between the end of one board and the middle section of another. The lapped section resembles a “V” or bird’s tail, which gives the joint a decorative look. The lapped dovetail joint is common in cabinetry and furniture making.

How To Cut A Lap Joint In Wood?

A lap joint is commonly used in construction settings for rafter framing systems. If you need to cut a lap joint, here are the steps to follow.

First, lay both boards on a work surface, such as the plywood decking. Place one board’s end on top of the other board’s end. Apply construction adhesive and drive a screw through the lap to secure the boards.

Next, adjust the boards to the appropriate angle. Typically, a lap joint is used for 90-degree angles. However, if your joint is different, you’ll need to calculate the correct angle.

After adjusting the boards, glue and screw through the lap joint. Use at least five screws or nails to fasten the boards together.

If your joint is anything less than 90 degrees, there will be excess wood to trim past the joint. To trim the excess wood, use a power tool like a reciprocating saw or circular saw to cut it flush with the end of the joint.

By following these steps, you can successfully cut a lap joint for your rafter framing system.

Applications

- Frame assembly in to make wooden cabinets.

- Temporary wood framing system.

- Some applications in timber framing.

- Construction industry.

- To make chair and tables.