Table of Contents

Lockout–Tagout (LOTO)

Lockout–Tagout (LOTO) refers to procedures to protect workers from the unexpected energization of equipment, or the release of energy during maintenance activities.

Lockout

The closure and placement of a lock on an energy isolating device, to ensure that the energy and the equipment or process can not be operated until the lock-out device is removed.

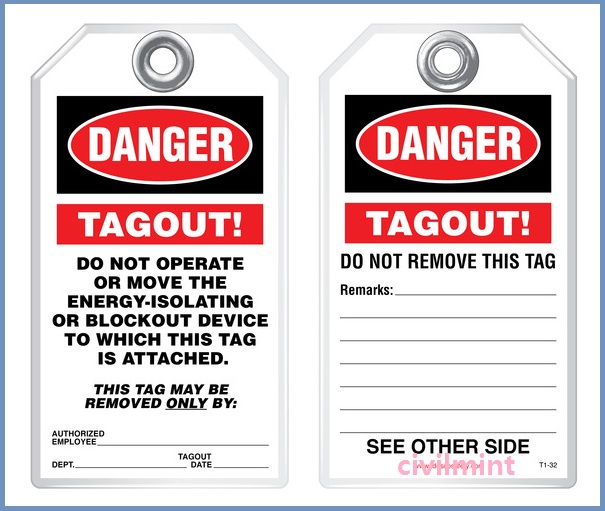

Tagout or Hold Tags

Do not operate warning devices to communicate the reason, the authorization of the isolation, and also identifies who performed the isolation in case they need to be contacted.

What is Isolation

Isolation is the process of:

- De-energizing equipment or machines.

- Removing the possibility of an unexpected startup of equipment or machines.

- Eliminating all sources of energy and stored energy.

When Do You Isolate:

- Any maintenance work.

- Repair work.

- Any work that requires a line break or equipment opening.

- Confined space entry.

Tagout Procedures

- When a tag is attached to an energy isolating device, it is not to be bypassed, ignored, or removed without the permission of the authorized person.

- Tags must be legible in order to be effective. When it is no longer, it must be replaced.

- Tags must be securely attached to the energy isolating device.

- Tags and their attachment must be made of materials that will withstand environmental conditions.

Energy Requiring Isolation

- Electrical energy

- Mechanical energy

- Steam energy

- Hydraulic energy

- Pneumatic energy

- Chemical energy

- Potential or stored energy

Equipment Requiring Isolation

In a mechanical system, consideration must be given to the different types and combinations of energy sources that may be present.

Let us take an example:

A mixing tank may have mechanical energy for the mixer, electrical for the motor, and chemical energy from the material inside the tank.

Here are some common examples of equipment that will require isolation:

- Pipelines.

- Electrical equipment.

- Pumps.

- Motors.

- Compressors.

- Pressured lines/Pipelines.

- Vessels, tanks, and confined spaces.

- Hydraulic presses.

- Fin fans.