Table of Contents

What Is Profometer Test?

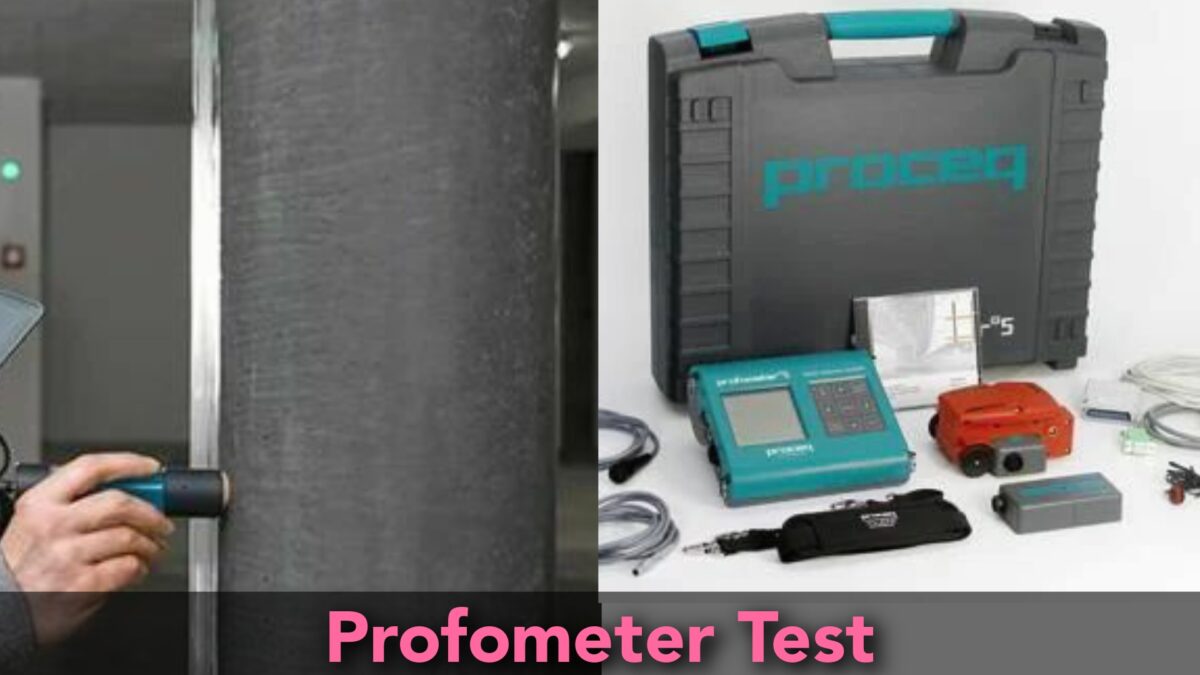

The Profometer test is a method employed to accurately and swiftly detect the location and dimensions of steel reinforcements and concrete cover in various structures.

This technique utilizes a compact and portable instrument known as a profometer or rebar locator.

The profometer device, weighing less than two kilograms, operates on standard batteries, eliminating the need for external electrical connections.

Its functioning relies on the principle that the presence of steel within a structure affects the surrounding electromagnetic field, which is precisely measured by the profometer.

The instrument features ample storage capacity to retain measured data, while integrated software facilitates intricate calculations and generates statistical reports for analysis and documentation.

The applications of the Profometer test are wide-ranging and significant. It is commonly employed to ascertain reinforcement size, determine their placement, and evaluate the condition of existing structures to check their actual strength.

Prior to drilling or cutting concrete for core testing, the Profometer test aids in accurately identifying the location of reinforcements.

It also serves as a valuable tool for corrosion analysis, conformity assessments, and quality assurance protocols.

Working Concept

The device operates by detecting alterations in an electromagnetic field, resulting from the presence of steel bars within the concrete structure.

Various Purposes Of Profometer Test

1. Identify Reinforcement Bars

One of the primary purposes of the Profometer test is to accurately assess the precise location of steel bars or reinforcement within a concrete structure.

By utilizing advanced electromagnetic induction principles, the test helps identify the presence, arrangement, and distribution of steel bars, enabling engineers and contractors to gain a comprehensive understanding of the reinforcement layout.

2. Measuring Diameter of Steel Bars:

Another key function of the Profometer test is to measure the diameter of the reinforcement bars used in concrete structures.

By employing electromagnetic measurements, the test allows for the precise determination of the bar diameters, providing crucial information regarding the structural integrity and load-bearing capacity of the reinforced concrete elements.

3. Evaluating Thickness of Concrete Cover:

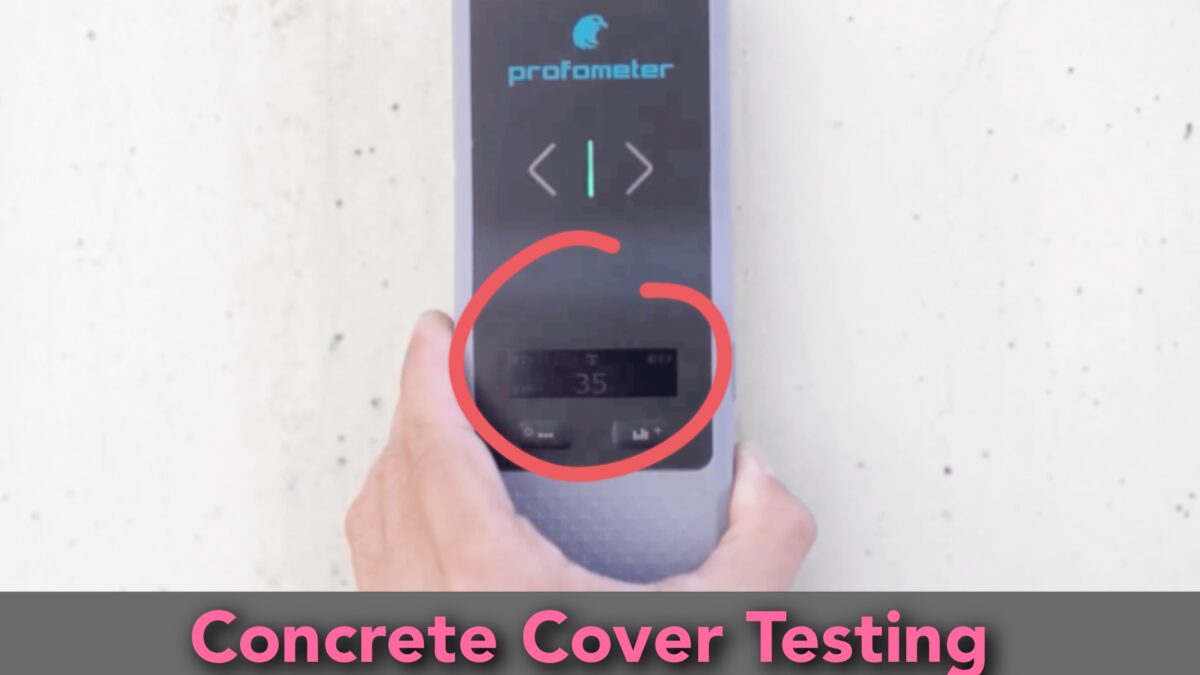

The Profometer test also plays a crucial role in evaluating the thickness of the concrete cover over reinforcement bars. By measuring the distance between the surface of the concrete and the underlying steel bars, engineers can assess whether the concrete cover meets the required standards and specifications.

This evaluation is vital as an adequate concrete cover protects the steel bars from corrosion, ensuring the durability and longevity of the structure.

Calibration Of Profometer

In order to ensure optimal functionality and precise results, it is necessary to calibrate the Profometer device before commencing operations and at the conclusion of the test. This calibration process is crucial for achieving satisfactory performance.

To facilitate the calibration, the accompanying test block, which is provided with the instrument, should be utilized. The test block serves as a reference for verifying the accuracy of the Profometer device.

During calibration, the Profometer equipment is employed to measure the dimensions and covering of the reinforcement at various locations on the test block. These measurements are then compared to the prescribed standard values specified on the test block.

It is imperative that the recorded data obtained from the Profometer equipment aligns with the standard values outlined on the test block. This ensures the reliability and accuracy of the Profometer device in providing precise readings.

By adhering to the calibration procedure and confirming the congruence between recorded data and standard values, the Profometer device can be relied upon to deliver accurate results, guaranteeing the effectiveness of its operations.

Profometer Test Procedure

1. Equipment Setup:

You will need a Profometer device, which consists of a handheld unit and a probe. Ensure the device is charged and functioning properly.

2. Calibration:

Before starting the test, calibrate the Profometer device according to the manufacturer’s instructions. This step ensures accurate measurements.

3. Preparation:

Clean the surface of the concrete structure where you plan to perform the test. Remove any loose debris, dirt, or coatings that may affect the readings.

4. Sensor Placement:

Attach the probe of the Profometer device to the concrete surface. The device will emit signals and measure the electromagnetic response from the reinforcing bars within the concrete.

5. Scanning:

Move the probe along the concrete surface in a systematic manner, following a grid pattern or predefined lines. The Profometer will detect the presence and location of the reinforcing bars.

6. Data Collection:

As you scan, the Profometer will display and record data related to the concrete cover thickness and potential corrosion. Take note of any irregularities or areas of concern.

7. Interpretation:

Analyze the data collected by the Profometer device. Look for areas where the concrete cover thickness is below the specified requirements or where corrosion is detected. These areas may need further investigation or maintenance.

8. Reporting:

Document your findings and provide a report with the test results. Include any recommendations for repairs or maintenance based on the data obtained from the Profometer test.

Advantages of Profometer Test:

- Profometer test does not break or damage the concrete structure.

- It gives accurate measurements of the thickness of the concrete cover and shows where the reinforcing bars are.

- The test is fast and doesn’t take a long time to finish.

- The machine used for the test is small and easy to carry around.

- It can be used on different parts of a building, like walls, floors, and columns.

- Besides measuring the cover thickness, it can also tell how deep the reinforcing bars are.

- The test results can be stored and analyzed later to make reports and compare data.

- Some machines show the rebar layout in real-time, helping to find any problems quickly.

- Profometer tests are cheaper than breaking the concrete to check it.

- The test follows international standards, so the results are reliable and trustworthy.

Disadvantages of Profometer Test:

- The test can only measure a limited depth, usually up to 6 inches.

- Before doing the test, the concrete surface needs to be cleaned and prepared properly.

- The accuracy of the test depends on how skilled the person doing it is.

- Profometer tests don’t give information about the quality of the concrete, like how strong or durable it is.

- The accuracy of the test results can be affected by things like humidity, temperature, and moisture in the air.

Faqs

Yes, the Profometer test can be used for many different concrete buildings like floors, walls, pillars, and beams. But it may not work well for buildings with thin concrete or strange shapes.

It usually takes a few minutes to test one spot with a Profometer. But if the building is big or needs a lot of testing, it might take a few hours or multiple visits to finish.

The Profometer test can find metal bars and measure how deep they are inside the concrete. But it can’t directly tell if they are rusty. However, it can give clues about areas where rust might happen, like places with less concrete covering the bars or with a lot of salt.

Yes, we need to make sure everyone doing the test is safe. They should wear special clothes like gloves and glasses. We also need to clean the concrete surface before the test, so there’s no dirt or stuff that can mess up the test.

Yes, the Profometer test is safe for old buildings. It doesn’t hurt them because we don’t need to drill or damage the concrete. We just put the test tool on the surface, and it gives us information about the building without making any big changes.