Table of Contents

Microfiltration Meaning

Microfiltration is a process that separates particles and impurities from a fluid using a special filter with very small pores. The size of the pores in the filter ranges from 0.1 to 1 microns, which is small enough to capture larger particles and microorganisms like bacteria.

Unlike other filtration processes like reverse osmosis and nanofiltration, microfiltration does not require pressure to work. It is often used to remove suspended solids from a fluid before using other filtration processes, or on its own as a standalone filtration method. This technique is widely used in industries such as food and beverage production, pharmaceutical manufacturing, and water treatment.

Working Principle

Microfiltration is a filtration process that utilizes a micrometer-sized (μm) filter to remove organic matter, suspended solids, small colloids, bacteria, and turbidity from fluids.

The filters used in microfiltration are typically porous and allow water to pass through them. The process can be carried out at atmospheric pressure or with a vessel at a certain pressure (maximum 25 psi), but it usually works at low pressures.

This technique is effective in removing a wide range of impurities from fluids, making it a popular choice in various applications, such as water treatment, food and beverage processing, pharmaceuticals, and biotechnology.

Applications Of Microfiltration

- Microfiltration is used as a pretreatment step to remove suspended solids, bacteria, and cysts from water before producing drinking water.

- Industries use microfiltration to remove suspended solids, bacteria, and other impurities from process water, making it suitable for reuse.

- Beverages and pharmaceuticals are sterilized with microfiltration, which preserves the taste and quality of the product without heat.

- The dairy industry uses microfiltration to separate milk proteins and fats, and to clarify milk.

- Fruit juices, wine, and beer are clarified using microfiltration to remove suspended solids, yeast, and bacteria.

- Microfiltration is used as a pretreatment step for reverse osmosis, removing suspended solids and bacteria from water before further treatment.

- Microfiltration is used to separate oil and water emulsions in industrial processes.

- Wastewater is treated with microfiltration, removing suspended solids and bacteria before discharging it into the environment.

- The metallurgical industry uses microfiltration to separate water/oil emulsions.

- The textile industry uses microfiltration to treat wastewater from manufacturing processes, removing suspended solids and bacteria.

Classification Of Seperation Membrane

One way to classify separation membranes is based on the size of their pore openings. This method categorizes membranes into four groups:

- Microfiltration: Membranes with pore openings ranging from 0.1 to 1 micron (μm)

- Ultrafiltration: Membranes with pore openings ranging from 0.01 to 0.1 μm

- Nanofiltration: Membranes with pore openings ranging from 0.001 to 0.01 μm

- Reverse osmosis (hyperfiltration): Membranes with pore openings ranging from 0.0001 to 0.001 μm

Difference Between Microfiltration And Ultrafiltration

The main difference between the two lies in the pore size of the membrane used and the separation mechanism employed. Microfiltration membranes have larger pore sizes compared to ultrafiltration membranes, resulting in lower molecular weight cut-off and particle size removal. While ultrafiltration membranes can use both sieving and adsorption mechanisms to remove particles and macromolecules, microfiltration membranes primarily rely on the sieving mechanism.

The choice of process to use depends on the specific application and the desired level of separation.

Here is the table comparing between microfiltration and ultrafiltration.

| Parameter | Microfiltration | Ultrafiltration |

|---|---|---|

| Pore size | 0.1 to 10 microns | 0.001 to 0.1 microns |

| Separation mechanism | Sieving | Sieving and adsorption |

| Solids removal | 60-99% | 90-99+% |

| Particle size removal | 0.1 to 10 microns | 0.001 to 0.1 microns |

| Molecular weight cut-off | <100,000 Da | 1,000 to 100,000 Da |

| Operating pressure | 0.1 to 10 bar | 1 to 10 bar |

| Applications | Clarification, sterilization, removal of bacteria and fungi | Separation of proteins, viruses, and other macromolecules |

Advantages Of Microfiltration

- Low operating pressure requirement

- Low energy consumption in semi-inactive units compared to other filtration techniques

- Virtually no manual operations are required

- It is relatively inexpensive

- It does not require energy-intensive phase transitions such as the evaporation technique

Disadvantages Of Microfiltration

- Sensitivity to oxidizing chemicals, which can damage the filter

- Hard and sharp particles larger than 0.1 mm can cause damage, requiring more pre-filtration

- Diaphragm can fail if flushed with pressure higher than 1 bar

- Limited filtration of particles smaller than 0.1 microns

- May not be suitable for all types of liquids or particles, requiring alternative filtration techniques for some applications.

Sum Up

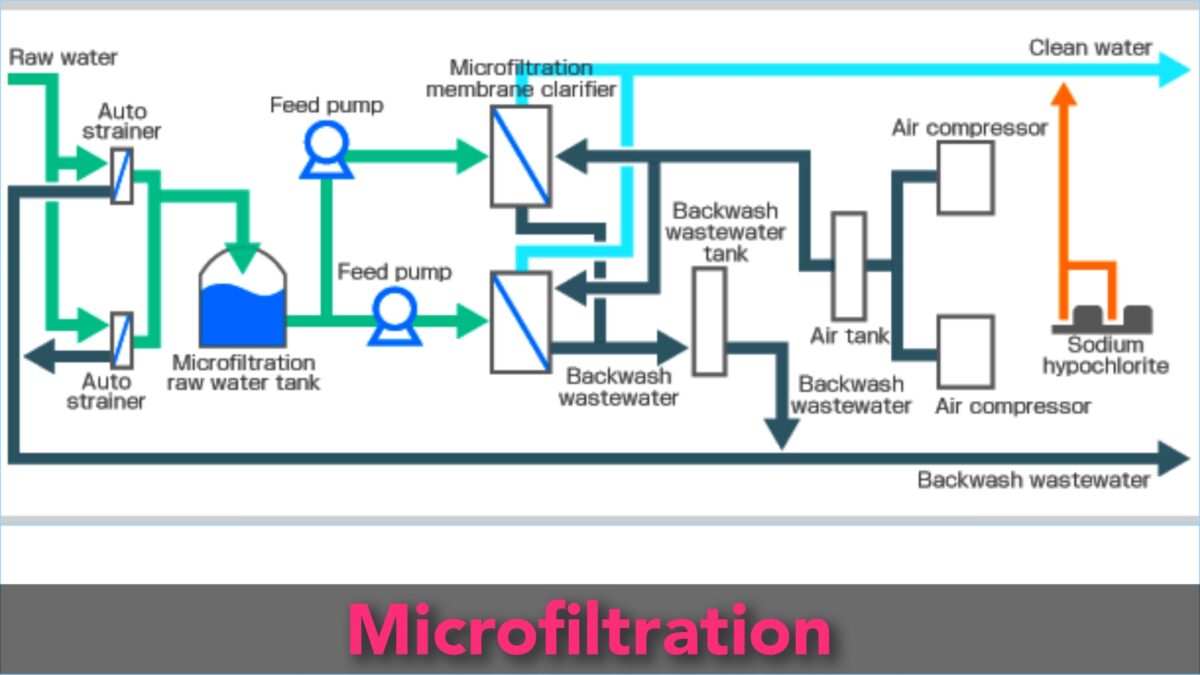

Microfiltration mainly operates in cross-flow and dead-end modes.

In cross-flow filtration, the stock solution flows across the membrane surface, and the concentrate continuously depolarizes the concentration used to clean the membrane.

Cross-flow filtration is preferred for filtering liquids with high concentrations of solids.

The typical cross-flow velocities in tubular module geometry are up to 6 m/s.

Cross-flow filtration causes trapped particles to accumulate on the membrane surface and form a filter cake.

The filtration flow rate decreases as the filter cake height increases during the filtration period.

Therefore, membranes must be regularly cleaned by backwashing, mechanical or chemical cleaning methods during dead-end operations.

Microfiltration is commonly used to filter aqueous solutions, especially in drinking water and beverage treatment.

Microfiltration is used in beer and wine filtration and milk and whey processing in beverage production.

Biotechnology uses microfiltration to retain biomass in fermentation fluid.

The separation of water and oil is the most important microfiltration operation in the metallurgical industry.