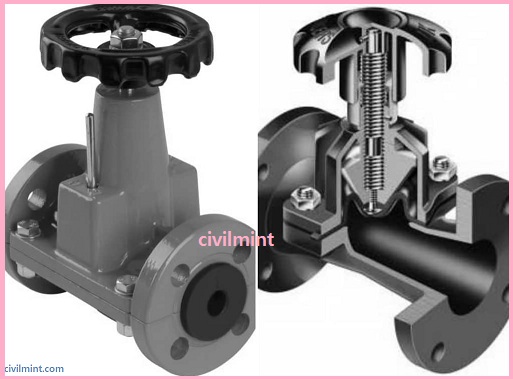

A pinch valve is a soft-bodied valve with a flexible tube that can “pinch” together by either mechanical or fluid pressure to completely shut off the flow of a fluid.

A pinch valve is also known as a tube valve. This valve has a linear motion. The pinch valve is a 2/2-way valve designed to control or block the flow of granular, abrasive, or corrosive liquids.

This type of valve is used to stop, regulate and start the flow of a liquid. They have a simple structure.

These valves have a straight flow path with no gaps or moving parts. A soft valve body can seal trapped solids. It is because of this feature that this valve is most suitable for processing pharmaceuticals, foodstuffs, and sewage sludge.

Synthetic or natural rubber is used for the manufacture of pins. In some cases, plastic is also used to make pinch pipes because the plastic has very good anti-wear properties.

The maximum pinch valve has an opening type with an open pinch tube. There is another style in which a metal body completely surrounds the pinch tube.

The latch valve has a light and lower maintenance costs than conventional valves. You can also use these valves in systems that require an explosion-proof plug.

These valves are best suited for aseptic production lines and applications where product purity is paramount, but the same designs have several disadvantages. They are not suitable for applications where liquids are transported at high temperatures. They are also not the best for services or gases that require high-pressure flows. They are best suited for slurry applications.

Table of Contents

How Does a Pinch Valve Work?

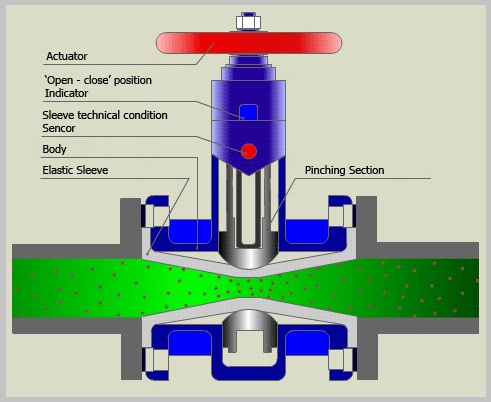

When high-pressure air presses against the valve, the air compress the rubber hose downwards and creates a pinching effect. When the rubber sleeve is fully pressed, the fluid flow is blocked and the valve closes.

The rubber sleeve of the shut-off valve is capable of trapping contaminant particles around it and providing exceptional shut-off performance, unlike other valves such as gate valves and ball valves which can also trap particles around. disc or ball.

The locking valve opens only when there is no force acting on it. Since no external pressure is exerted on the rubber sleeve, its elastic properties and the force of the flowing fluid cause the valve to open fully.

A fully open valve allows fluid to flow freely to prevent the valve from sticking or clogging. Since the liquid is only in contact with the rubber sleeve, the liquid is isolated and does not contaminate or damage any part of the valve.

Benefits of Pinch Valve

- These valves are ideal for corrosive or abrasive fluids.

- They do not need an additional or special actuator.

- They have a straight flow path. Therefore, they do not create blockages or blockages in the flowing fluid.

- There is very little turbulence and friction.

- No packaging, bearings, or seals are required.

- The shut-off valve ensures an uncontaminated liquid flow.

- It has easy maintenance.

- It is self-cleaning.

- They consume less energy than other valves.

- These valves have low maintenance and repair costs.

- They have the excellent sealing ability.

- They have a quick operation.

Some Drawbacks of Pinch Valve

- These valves are not ideal for high-temperature applications due to the elasticity of the sleeve.

- In the event of a large pressure difference, the rubber sleeve may become deformed or stamped and the valve will not fully open.

- They are not ideal for vacuum services because suction in the valve can damage the sleeve.

- The operating pressure of the working fluid is limited.

Application/Uses

- Industrial Wastewater

- Plastic Industry

- Ceramic Industry

- Batch and Solids Processing Industry

- Cement Industry

- Beverage and Food Industry

- Chemical Industry

- Pharmaceutical Industry

Thanks for reading my article on Pinch Valve. If you have any thoughts, hit the comment box.

Thanks!

Happy Learning!

Ta! Da!