A plunger pump is a well-known type of reciprocating pump with a fixed high-pressure seal and a smooth cylindrical plunger that slides over the seal. These two characteristics of the plunge pump make it different from the piston pump. It can generate higher pressure than a piston pump. Therefore, it may use for high-pressure applications.

Piston pumps and plunger pumps use chambers that expand and contract to draw and pressurize liquids. Because they are reciprocating pumps, the chamber expands and contracts due to the reciprocating motion of the plunger, not the circular motion.

Plunger pumps are also known as high viscosity pumps or high-pressure pumps because they provide high pump pressure. These pumps can also carry both solid and viscous media. These piston pumps are used to pump industrial and urban wastewater.

Table of Contents

How Does Plunger Pump Work?

Plunger pumps have a fixed seal on the stuffing box instead of a piston. Connecting rods, crankshafts, and pistons are the main components of piston pumps.

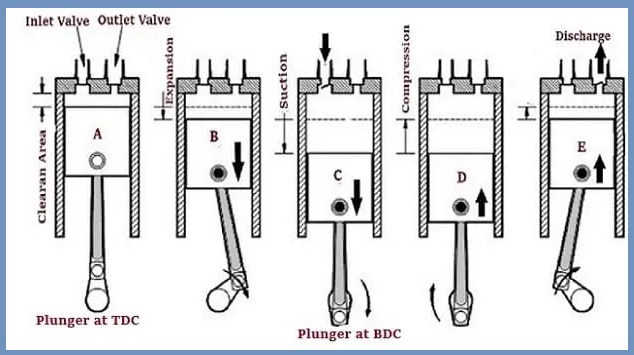

The plunger pump works as follows:

- The plunger of the pump is connected to the crankshaft via a connecting rod. This crankshaft is also connected to an electric motor.

- When the engine powers the crankshaft, it converts the rotational motion of the engine into reciprocating motion. The crankshaft transfers this force to the piston via the connecting rod.

- When the piston is given reciprocating motion, the piston begins to move up and down in the cylinder.

- When the piston goes down, a vacuum is created in the pump chamber. This vacuum creates a pressure difference between the fluid pressure on the outside and the fluid pressure on the inside of the cylinder.

- The piston then draws the liquid into the chamber. Suctioning the liquid according to your requirements closes the suction valve and raises the piston. As the piston rises, the volume of the chamber decreases, and the fluid is pressurized.

- When the internal fluid pressure rises above the supply tank pressure, the outlet valve opens to direct the fluid to the supply tank or other desired location.

Types of Plunger Pumps

The popular types of plunger pumps are listed below.

- Duplex pump

- Simplex pump

- Triplex plunger pump

- Multiplex pump

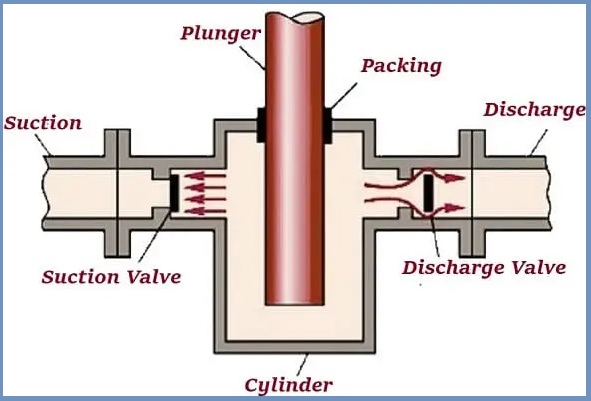

Components or Parts of Plunger Pump

- Plunger

- Suction Valve

- Discharge Valve

- Cylinder

- Seal

Refer to the below image to visualize it better.

Uses of Plunger Pump

- These pumps are used to inject chemicals.

- These pumps are also used for odor control and mist

- Use a piston pump for drill cutting injection

- Used for cutting water

- Use in oil and gas production

- Plunger pumps are also used for gas drying

- They are used for surface treatment

- Plunger pumps are also used in the production of urea

- They are used for cleaning applications

- These pumps are used for coal liquefaction

- These are used for pressure testing