A rotary valve is a type of valve in which the rotation of the lateral plug passage controls the flow of fluid through the installed piping. A common stopcock is the simplest form of the rotary valve.

Table of Contents

Types of Rotary Valves

- Quick-Take-Apart (QTA) Series Rotary Airlock

- BAV Rotary Airlock Valve

- Dust Collector Series

- Abrasion Resistant Rotary Airlock Valve

- Heavy-Duty PAV Series

- Blow-Thru Rotary Airlock Valve

1. Quick-Take-Apart (QTA) Series Rotary Airlock

For material handling applications that require quick cleaning or frequent removal of the internal components of the rotary valve, Prater’s QuickTakeApart (QTA) series rotary valves also allow the rotor and endplate to be removed in one piece, safely and toolless. Designed for.

Like the BAV series, the QTA is designed to increase production efficiency by eliminating the time-consuming step of “gapping” the rotor during assembly, but rails when space is limited. It will be a less package. QTA is made of cast iron or stainless steel. 6-inch and 8-inch models are available. QTA is ideal for applications that require frequent cleaning and switching.

2. BAV Rotary Airlock Valve

Prater’s BAV series rotary valves are ideal for material handling applications that require rapid cleaning or frequent removal of the internal components of the rotary valve.

The BAV series features a removable rotor and rail system that allows the endplate and rotor to be safely and tool-free as a single part. These standard BAV features improve production efficiency in the following ways:

- Quick and easy disassembly for maintenance, cleaning, and inspection.

- Eliminates the time-consuming step of “splitting” the rotor during assembly.

- Protects against operator overload and component damage caused by component handling in difficult and vulnerable locations.

- Self-centering rotor for quick reassembly.

BAV is made of stainless steel. Drop-through styles are available in 6-inch, 8-inch, 10-inch, and 12-inch models, and blow-through styles are available in 8-inch, 10-inch, and 12-inch models. Series BAV rotary valves are ideal for applications that require frequent cleaning or switching.

3. Dust Collector Series

The dust collector series rotary valves are ideal for applications used to eject material from dust collectors and hoppers. These types of rotary valves are designed for applications with minimal differential pressure at low temperatures.

Dust Collector Series Rotary Valves provide air seals that are not supplied at certain speeds. These are rugged designs with eight bladed rotors, making them economical and accurate machines.

Economical, budget-friendly, standard rugged design features an 8-blade rotor, precision machining, and a rugged cast iron body. The dust collector series rotary valves can be easily configured to meet the needs of most applications.

4. Abrasion Resistant Rotary Airlock Valve

Abrasion-resistant rotary valves are designed for applications that take a step beyond the Heavy-Duty PAV series when it comes to highly abrasive or corrosive material handling requirements.

The ceramic-lined cast iron body withstands the most abrasive and corrosive products and applications. It is the most durable and wear-resistant rotary valve available and provides a solution for other rotary valves that wear prematurely.

The wear-resistant rotary valve is designed to provide high performance with less maintenance. They are placed in a case and then polished to meet their accuracy tolerances. They are superior to other types of rotary valves on the market.

5. Heavy-Duty PAV Series

As the name implies, the Heavy Duty PAV series is a versatile rotary valve for transferring many dry, free-flowing powders from large containers to pneumatic systems, with pressures up to +/- 15 PSI. Designed to maintain the difference.

These valves are made of stainless steel or cast iron. These are rugged PAV series rotary valves built for high-temperature applications up to 500 ° F. The high-temperature service kit can be used for extreme applications up to 1,000 ° F.

Optional coatings (chrome, tungsten carbide, etc.) and structural materials are available for handling abrasive or corrosive materials. Heavy-Duty PAV Series rotary valves are available to companies of all sizes and types when material handling requires the transportation of dry bulk materials.

5. Blow-Thru Rotary Airlock Valve

As the name implies, BlowThru rotary valves are specially designed and manufactured for processes that require guidance to the air transport line. The innovative and large scoop pocket design is ideal for free-flowing materials and handles up to 50% more volume.

Increasing the volume will allow the rotor to run at lower speeds, increasing efficiency and reducing wear. BlowThru valves are designed to minimize air leaks, keep pressure drops low, require low maintenance and increase the return on investment.

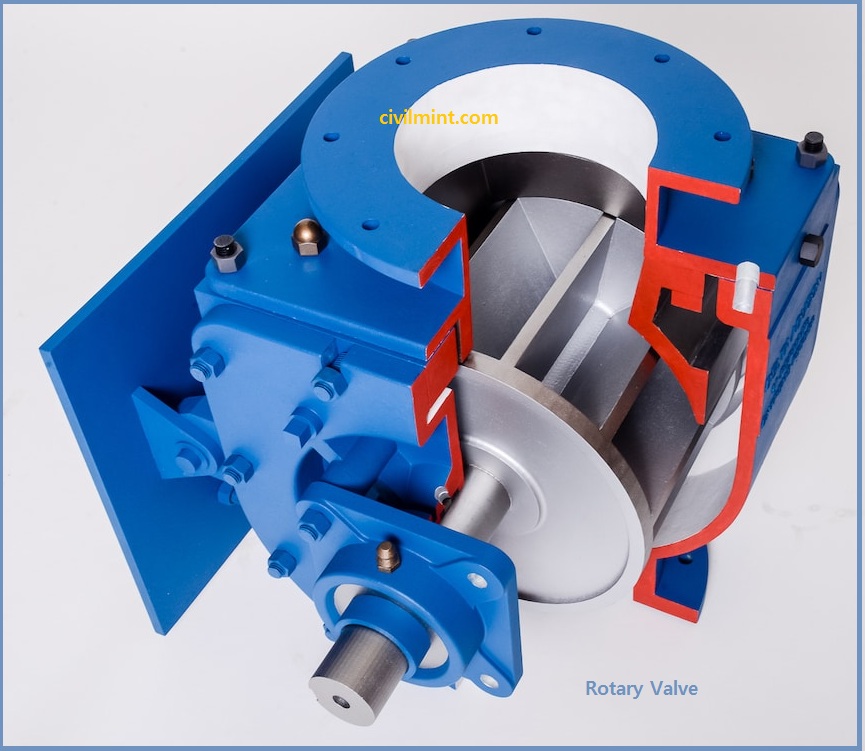

Components of Rotary Valve

- Drive

- Rotor Bearing and Seal

- Rotor

- Housing

Uses of Rotary Valve

- Pneumatic promotion

- Frequent cleaning / abiotic applications

- Change the pitch of brass instruments. Hydraulic power steering control valves for most automobiles. Plastic manufacturing

- Control of steam and exhaust ports of steam engines, especially in the Corris steam engine. Abrasive transport/administration

- It periodically reverses the flow of air and fuel through the open-hearth furnace. Applications in pharmaceutical manufacturing

- Load the sample into a chromatography column. Chemical and food processing applications

- Several types of 4-stroke and 2-stroke