Table of Contents

What Is Shield Tunneling?

Shield tunnelling is a temporary support structure used during the excavation of large, man-made tunnels. It is used to protect workers and the project from falling materials or cave-ins when excavating through soft, liquid, or unstable ground.

The shield is typically in place for the short-term until the tunnel section can be lined with a permanent support structure, which may be made of materials such as bricks, concrete, cast iron, or steel. The shield protected the workers from cave-ins while they excavated the tunnel in front of it.

Description

Shield tunnelling is a method of constructing tunnels that uses a shield machine. This method is considered safe and efficient, however, it does have some limitations. One limitation is that the efficiency of the shield machine can be affected by the geological conditions of the area. Additionally, it can be difficult to change the configuration of the shield machine or switch to a different construction method once the tunnelling process has begun.

To avoid problems during construction, it is essential to conduct a thorough geological survey before starting a shield tunnel project. This survey will provide information about the geological conditions of the area and will help identify and evaluate any existing geotechnical engineering or environmental problems. It should also propose appropriate solutions to ensure the safe, reliable, and economic construction of the shield tunnel.

However, if the geological survey is not done properly, it can lead to accidents during construction. For example, if the survey does not accurately identify the presence of gravel in a silt stratum, using an extruding shield machine could result in a gushing accident. Similarly, if methane gas is not detected and emergency measures are not taken, it could lead to accidents and loss of life.

To avoid these problems, it is essential to conduct a meticulous geological survey for each shield tunnel project. This survey should be done with care and should provide the necessary information for all stages of the project. It is important that the survey is conducted with the necessary care and attention to detail to ensure the safe and successful completion of the shield tunnel project.

Shield Tunneling Method Explained

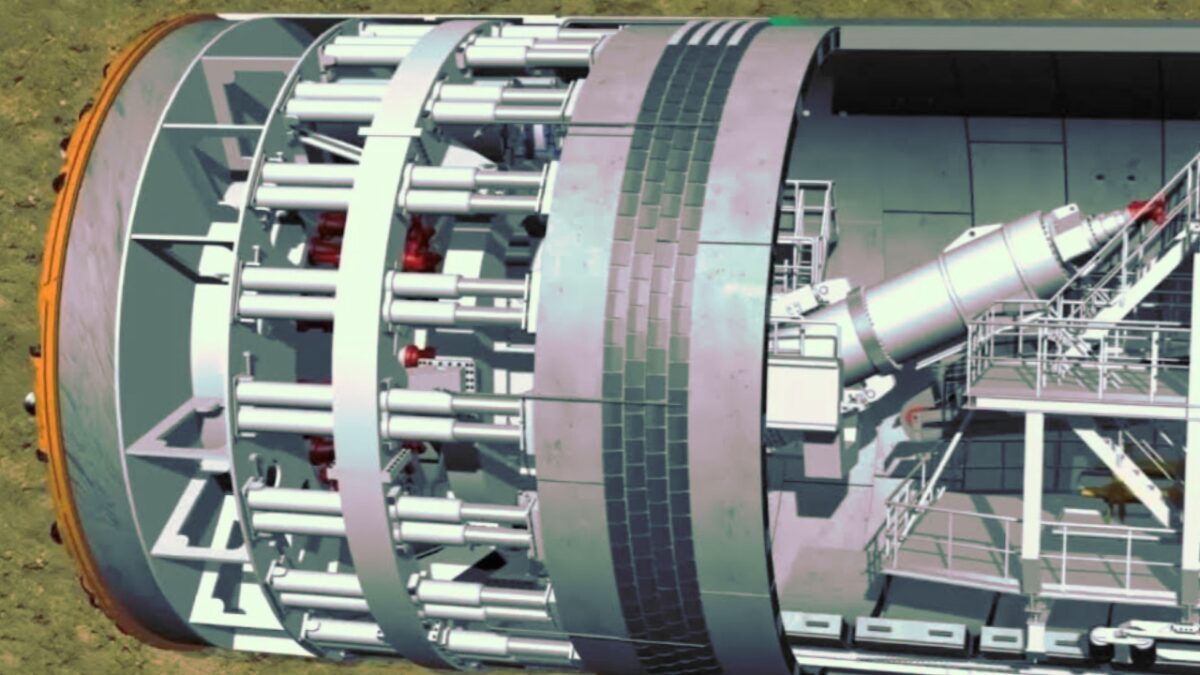

The shield tunneling method is a technique used to construct tunnels without excavating trenches. This method involves the use of a shield, which is a protective metal cylinder. The shield acts as a temporary support structure to prevent the surrounding soil from becoming unstable.

The shield also houses various mechanisms such as soil removal systems, slurry pipelines, control rooms, and rails for transporting lining segments. The method involves a rotating cutting head positioned at the front of the shield that advances the boring machine through the soil.

Once the tunnel is bored, a stable support structure such as concrete lining segments is put in place. Depending on the project, this method may be done with drilling slurry or without it.

Similar to other trenchless drilling methods, soil is removed from the borehole to the surface during shield tunneling. The shield Tunneling method is critical in large tunnels, where extreme ground pressures can result in cave-ins and other safety hazards.

How It works

Shield tunnel boring is a method used to excavate underground tunnels. It involves two main phases: the tunneling phase and the ring building phase.

During the tunneling phase, a rotating cutting wheel at the front of the shield machine grinds and breaks up the soil, which is then removed by a screw conveyor system. The machine also uses hydraulic jacks to push forward and create a tunnel opening.

Once the shield and cutting head have advanced a certain distance, the ring building phase begins. This involves using a mechanical transportation system to install new segments of lining under the shield, which provide support for the cutting head to continue tunneling.

In some cases, water, bentonite, or foam may be injected into the tunnel face to help stabilize the soil. In unstable soils, additional support pressure may be applied behind the cutting wheel to counteract instability.

It’s important to maintain a balance between the amount of soil removed by the conveyor system and the amount removed by the tunneling process to ensure optimal support for the tunnel face. The end result is a smooth and stable underground tunnel.

FAQS

Shield tunneling is a trenchless method used for larger diameter utility and crossing tunnels. It involves using a steerable shield and digger arm for excavation and ground stabilization.

Typical drive lengths for shield tunneling projects range from 50 to 1200-lf, but can vary depending on project details.