Table of Contents

What Is Wind Tunnel?

Wind tunnel is a machine used to test how objects interact with moving air. They help us understand how things like airplanes, cars, and buildings behave in different airflow conditions.

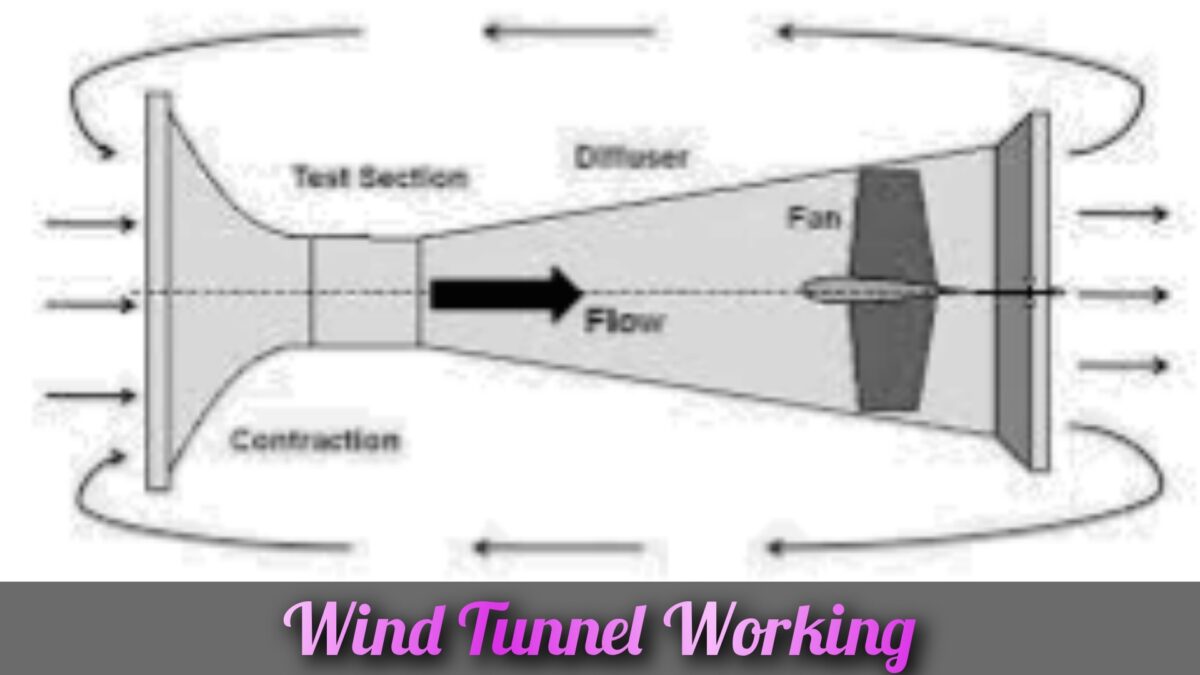

In a wind tunnel, an object is placed inside a tube, and air is blown around it. Large fans create the airflow, while the object stays still. The object can be something like a model airplane wing or a small-scale version of a car.

We can measure different things during these tests. For example, we can measure the forces that the air exerts on the object or the air pressure at different points. To see how the air moves around the object, we might use smoke or attach small threads to specific parts.

Nowadays, we also use wind tunnels to test sporting equipment like golf clubs and race car helmets. By studying the aerodynamics of these objects, we can improve their performance and safety.

While computer simulations have become more advanced, wind tunnel testing is still necessary for some things.

There are still real-world problems that computers cannot solve accurately enough, so physical testing in wind tunnels is still important.

Concept Of Wind Tunnel Testing

In wind tunnel testing, we blow air over or around the model in the tunnel, creating airflow similar to what the object would experience in real-world conditions.

We equip the model with sensors and instrumentation to measure various aerodynamic parameters such as lift, drag, and turbulence.

These measurements provide valuable data about the object’s performance, stability, and efficiency under different wind speeds and angles of attack.

Types Of Wind Tunnels

1. Open-Circuit Wind Tunnel

The open-circuit wind tunnel consists of a long test section with a fan at one end and an exhaust at the other. It is called “open circuit” because the air is drawn from the surrounding environment and then discharged after passing through the test section. This type of wind tunnel is commonly used for low-speed testing, such as aerodynamic studies of cars, buildings, and other stationary objects. The fan creates a continuous airflow through the test section, allowing researchers to measure the forces and pressures acting on the models placed inside.

2. Closed-Circuit Wind Tunnel

In a closed-circuit wind tunnel, the air is recirculated within the system, creating a continuous flow for testing. This type of wind tunnel is especially useful for high-speed testing, where maintaining a steady and controlled airflow is crucial. The closed circuit ensures that the air undergoes minimal changes in temperature and humidity during the testing process. By recirculating the air, it becomes more efficient and allows for long-duration testing. Closed-circuit wind tunnels are commonly used for aerodynamic research on aircraft, missiles, and high-speed vehicles.

3. Supersonic Wind Tunnel

Supersonic wind tunnels are designed to generate and study high-speed airflows exceeding the speed of sound. They are used to investigate the behavior of objects flying at supersonic speeds and to assess their aerodynamic performance. These wind tunnels employ specially designed nozzles to compress the air and achieve supersonic velocities. The test section in a supersonic wind tunnel is often shaped like a converging-diverging nozzle to maintain supersonic flow conditions. Researchers use supersonic wind tunnels to study phenomena such as shock waves, boundary layer behavior, and wave drag.

4. Subsonic Wind Tunnel

A subsonic wind tunnel is used to simulate airflows at speeds lower than the speed of sound for various testing purposes. Subsonic wind tunnels are commonly employed in aerodynamic research, such as testing aircraft and automobile designs. They are designed to accurately replicate the flow conditions experienced by the object being tested. Subsonic wind tunnels can produce different airflow velocities, allowing researchers to investigate various flight regimes and optimize the design of vehicles and structures for optimal performance.

5. Transonic Wind Tunnel

A transonic wind tunnel is capable of simulating airflow conditions at both subsonic and supersonic speeds. Transonic flow refers to the range of speeds near the speed of sound, where both subsonic and supersonic effects are present. These wind tunnels employ variable Mach number nozzles or other mechanisms to generate airflow velocities within the transonic range. They are essential for studying the complex aerodynamic phenomena that occur when an object transitions from subsonic to supersonic speeds, such as shock waves and boundary layer interactions.

6. Cryogenic Wind Tunnel

The cryogenic wind tunnel uses extremely low temperatures to study the effects of cold air on aircraft and spacecraft components. By cooling the air to cryogenic temperatures, researchers can simulate the conditions encountered at high altitudes or in space. This allows for testing the performance and behavior of materials and equipment under extreme cold conditions. Cryogenic wind tunnels are vital for evaluating the thermal management systems and structural integrity of aerospace vehicles and their components.

7. Water Tunnel

A water tunnel is a specialized type of wind tunnel that uses flowing water instead of air to simulate hydrodynamic conditions. Water tunnels are primarily used for studying the behavior of underwater objects, such as ships, submarines, and marine structures. The flowing water creates forces and pressures on models placed inside the tunnel, allowing researchers to investigate the hydrodynamic performance and stability of the objects. Water tunnels are particularly useful in the design and optimization of naval vessels and offshore structures.

8. Blowdown Wind Tunnel

A blowdown wind tunnel operates by storing compressed air, which is rapidly released to create a high-speed airflow for testing.

The blowdown wind tunnel works on the principle of releasing a large volume of compressed air in a short period, creating a high-pressure surge that propels the airflow through the test section. This rapid release of air generates high-speed flow conditions required for testing aerodynamic forces and phenomena. Blowdown wind tunnels are typically used for short-duration tests and can provide a wide range of airflow velocities depending on the amount of stored compressed air.

9. Suction Wind Tunnel

A suction wind tunnel generates airflow by drawing air through a test section, simulating the effects of relative motion. It works by creating a pressure difference between the test section and the surrounding environment, causing the air to be sucked into the tunnel. This type of wind tunnel is useful for studying the aerodynamic properties of objects in motion, such as airplanes, cars, or projectiles. By controlling the suction velocity, researchers can simulate different flight conditions and evaluate the performance and stability of various designs.

10. Industrial Wind Tunnel

The industrial wind tunnel is a large-scale facility used for testing large structures such as buildings, bridges, and vehicles under realistic wind conditions. These wind tunnels are designed to replicate the complex airflow patterns and turbulent gusts experienced in real-world environments. Industrial wind tunnels typically have a large test section capable of accommodating full-scale or scaled-down models. They are essential for assessing the structural integrity, aerodynamic behavior, and safety of structures subject to wind loads, contributing to the development of robust and efficient designs.

Faqs

Wind tunnel test results are analyzed through data analysis and visual observations to understand aerodynamic forces and flow patterns.

Wind tunnels offer controlled conditions, real-world simulations, early design evaluation, an iterative design process, and physical validation.

Yes, specialized wind tunnels can simulate extreme weather conditions like high winds and heavy rain for testing structures.

Limitations include scale effects, Reynolds number limitations, cost and time constraints, and the need for accurate model fidelity.

Safety precautions involve personnel training and protective gear, secure model mounting, electrical safety measures, proper ventilation, and established emergency procedures.