This article explains slump test, procedure of slump test, slump test table and slump cone test value. This test also called slump cone test.

Table of Contents

What Is Slump Test

A slump test or slump cone test is the most commonly used method to check the consistency and workability of the concrete mix prepared at the construction site during the progress of the work. It is carried out conveniently as a control test and gives an indication of the uniformity of concrete from batch to batch.

Factors Impacting Slump Cone Test Of Concrete

To produce high-quality and durable concrete, various factors must be considered, and appropriate measures implemented. These factors include monitoring the material properties of cementitious materials, such as their chemistry, fineness, particle size distribution, moisture content, and temperature. The size, texture, combined grading, cleanliness, and moisture content of the aggregates should also be monitored.

The dosage, type, combination, interaction, sequence of addition, and effectiveness of chemical admixtures must be carefully controlled. Excessive air in the concrete should be prevented, and proper batching, mixing, and transporting methods and equipment should be used to ensure a homogeneous mix, while maintaining the correct temperature.

Accurate testing results are crucial, and therefore, proper sampling techniques, the slump-testing technique, and the condition of the test equipment must be monitored. The amount of free water in the concrete and the time since mixing are also important factors that must be considered. By taking these various factors into consideration and implementing appropriate measures, consistent strength and durability of high-quality concrete can be achieved.

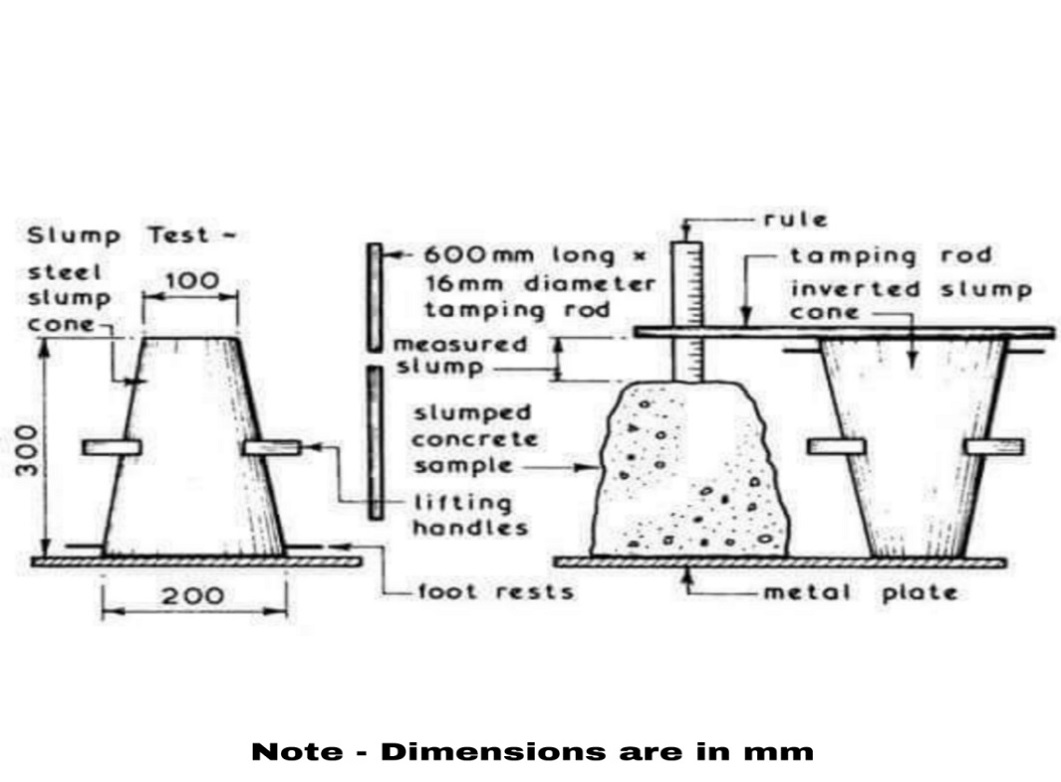

Equipments Required For Slump Test:

- Standard slump cone.

- Tamping rod.

- Waterproof Baseplate.

- Trowel.

- Measuring Tape.

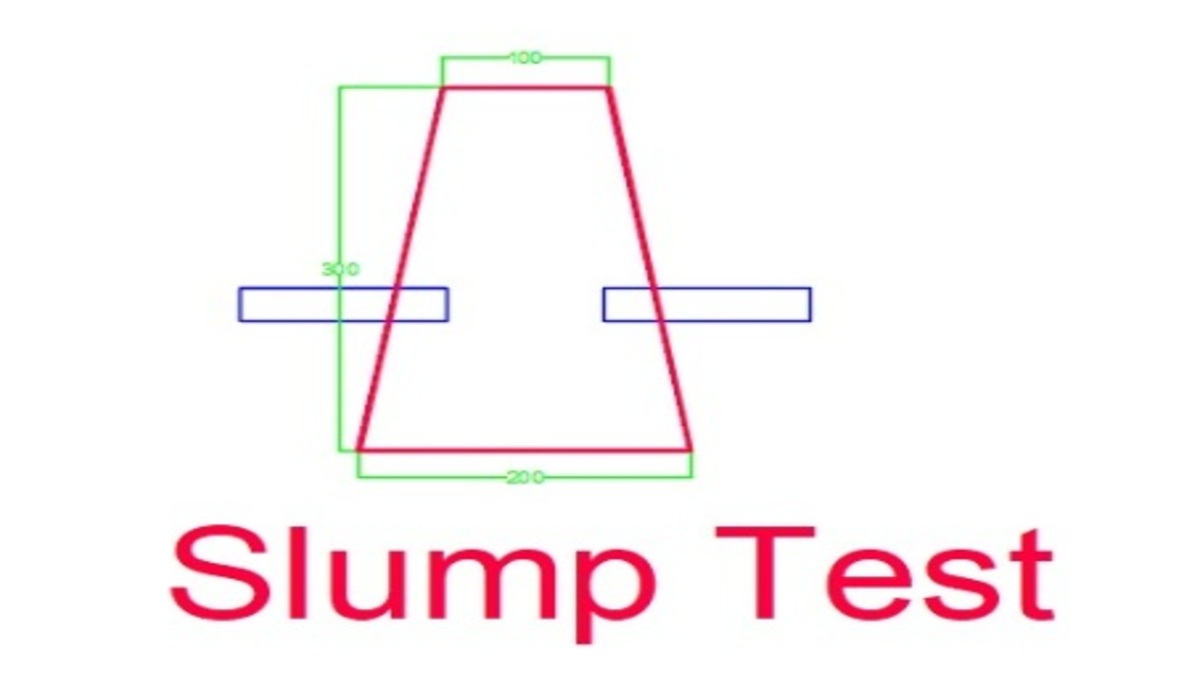

Slump test apparatus is shown below:

Slump Test Procedure

- The internal surface of the standard slump cone is thoroughly cleaned and freed from superfluous moisture.

- The slump cone is placed on a smooth, horizontal waterproof base plate.

- The slump cone is then filled with concrete in 4 layers (75mm each) tamping each layer 25 times with the help of a tamping rod.

- After the top layer has been tamped, the excess concrete is removed and the surface is leveled with a trowel.

- Then, the slump cone is removed by lifting it slowly and carefully in a vertical direction which allows the concrete to subside. This subsidence is referred to as a slump of concrete.

Types Of Slump

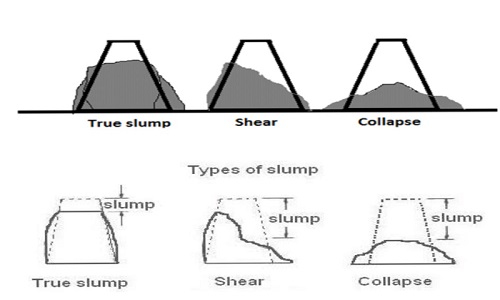

Three types of a slump are possible as given below.

- True Slump

- Shear Slump

- Collapse Slump

Let us discuss these types of slumps.

1. True Slump:

It refers to the general drop of the concrete mass evenly all around without disintegration. This type of slump is most desirable.

2. Shear Slump:

It indicates that the concrete lacks cohesion. It may go through segregation and bleeding and thus is undesirable for the durability of concrete.

3. Collapse Slump:

It indicates that the water-cement ratio in the concrete mix is too high and the mix is regarded as harsh and leaner.

Slump Test Table

| Sr. No | Structure Type | Min. Slump Value (mm) | Max. Slump Value (mm) |

| 1 | Columns | 75 | 125 |

| 2 | Rcc beam & slab | 30 | 125 |

| 3 | Pavements | 25 | 50 |

| 4 | Rcc Foundation & wall | 50 | 100 |

| 5 | Rcc Wall | 50 | 100 |

| 6 | Bridge & Flyover deck | 25 | 75 |

| 7 | Footing without reinforcement | 25 | 75 |

Limitation Of Slump Cone Test

The slump test assesses the workability of concrete with a slump in the range of 5 – 260 mm, which is considered to be of medium to low workability.

This test is not effective for determining the workability of stiff mixes that have zero slump or wet mixes that exhibit a collapse slump. Slump cone test is only suitable for concrete that is composed of aggregates that are smaller than 38 mm.

Faqs

True slump, Shear Slump And Collapse Slump.

Slump value is the height difference between the height of the mould and the average value of the subsidence.

To check consistency and workability of fresh concrete.